Check all the boxes

Each configuration of the »smileCheck« and »smartCheck« stands for top performance in tool inspection. Below you will find a comparison of the most important features. We are happy to delve more into these solutions during a one-on-one consultation from the ZOLLER Smart Factory.

Features in comparison

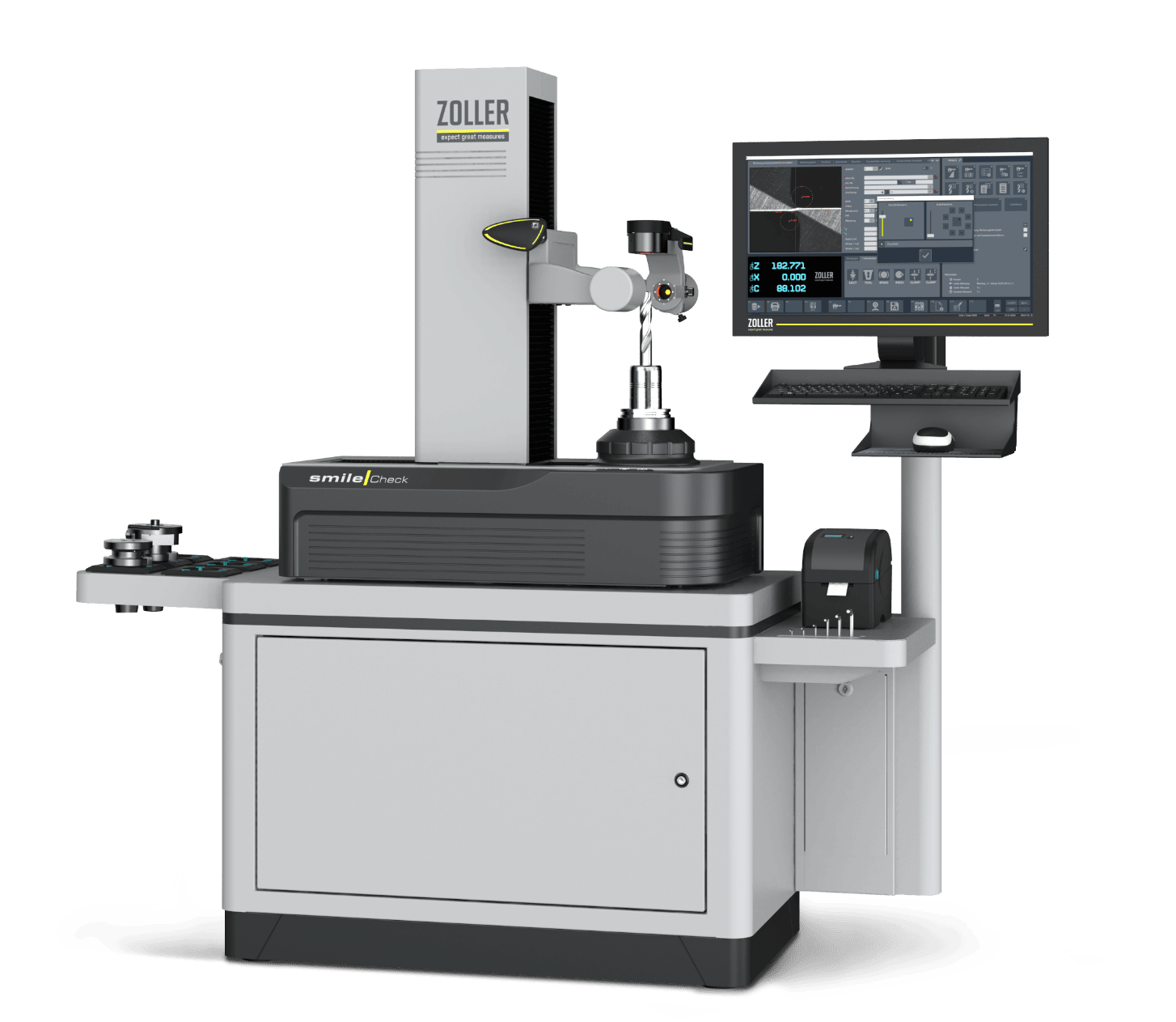

»smilecheck«

»smartCheck«

CNC control for Z-axis and X-axis

CNC control for Z-axis and X-axis

CNC control and rotary encoder for the C axis (autofocus)

CNC control and rotary encoder for the C axis (autofocus)

—

Swiveling optic carrier for inspection of threading tools

Single-segment LED illumination in incident light

LED illumination in incident light can be segmented

Monitor holder with keyboard shelf

Variable control unit »cockpit«

SK50 spindle

Spindle »ace« with power-operated tool clamping

Default camera systems for transmitted light and incident light

Premium camera systems for transmitted light and incident light

Measuring range Z-axis 420 mm

Measuring range Z-axis 600 mm

Tray for list printer

Tray for list printer

Data output

Data output

Measuring program package »inspectionBasic«

Measuring program package »inspectionPremium«