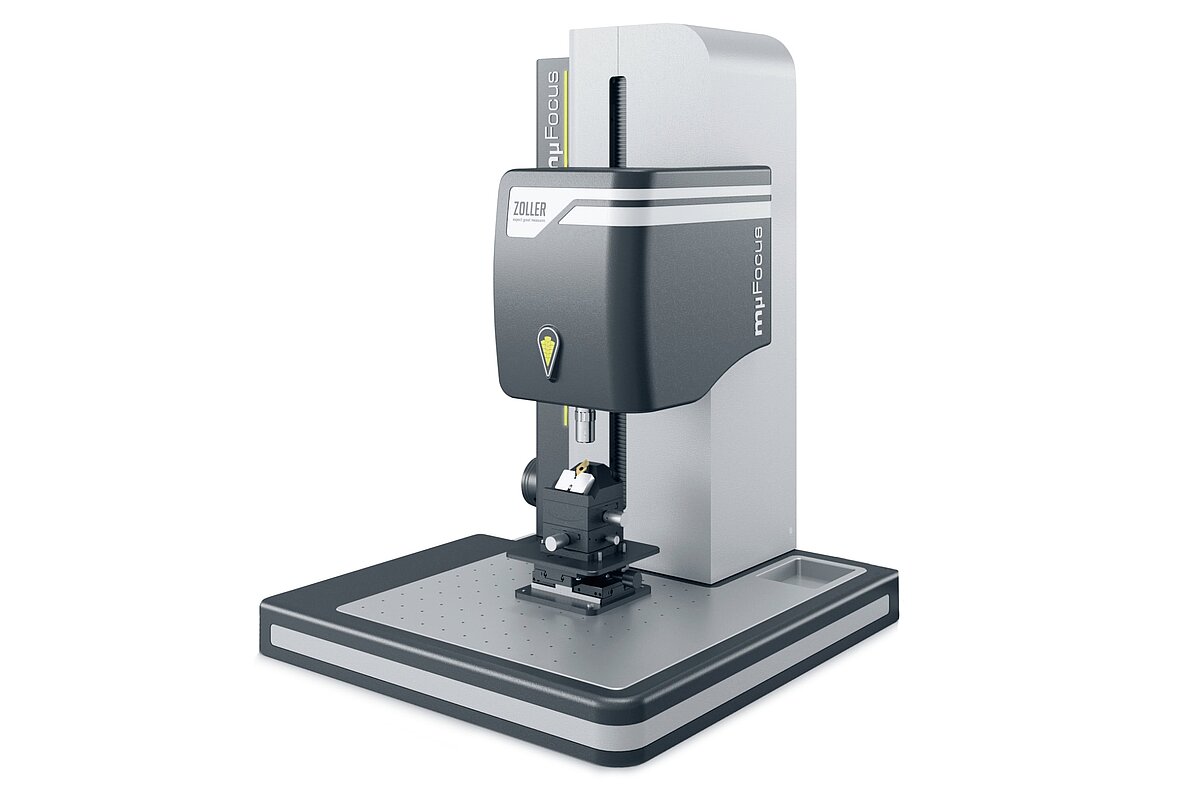

The 0.1 µm solution

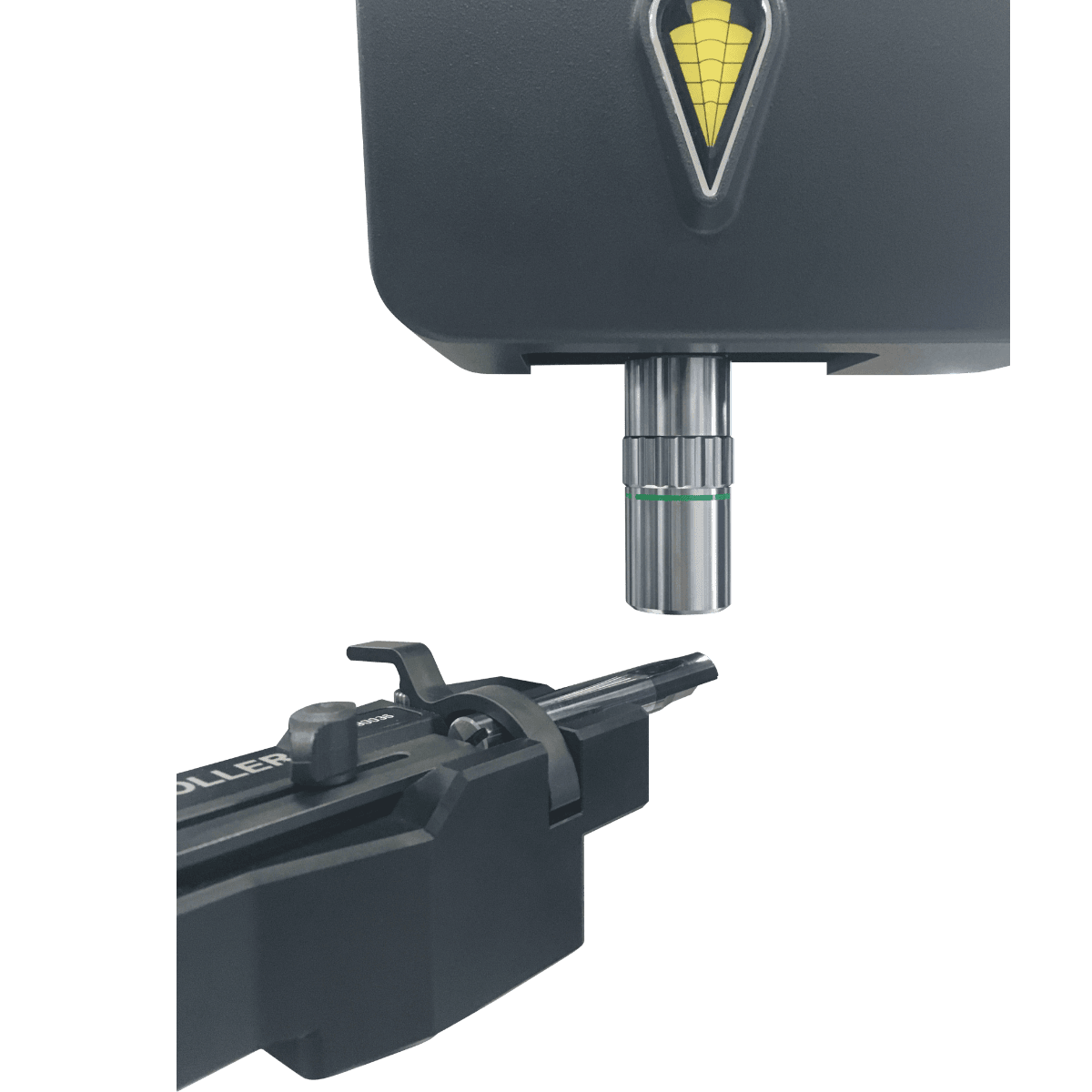

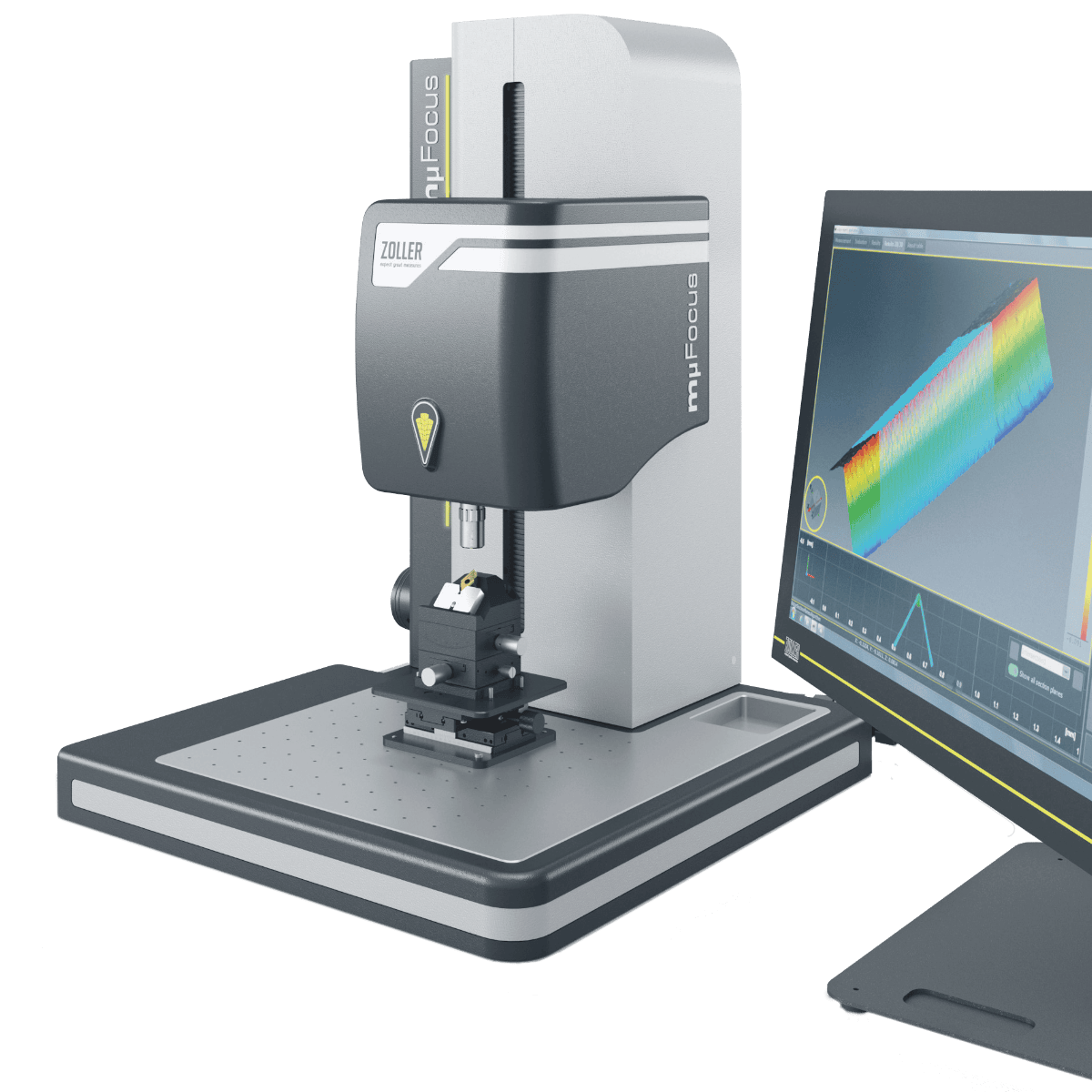

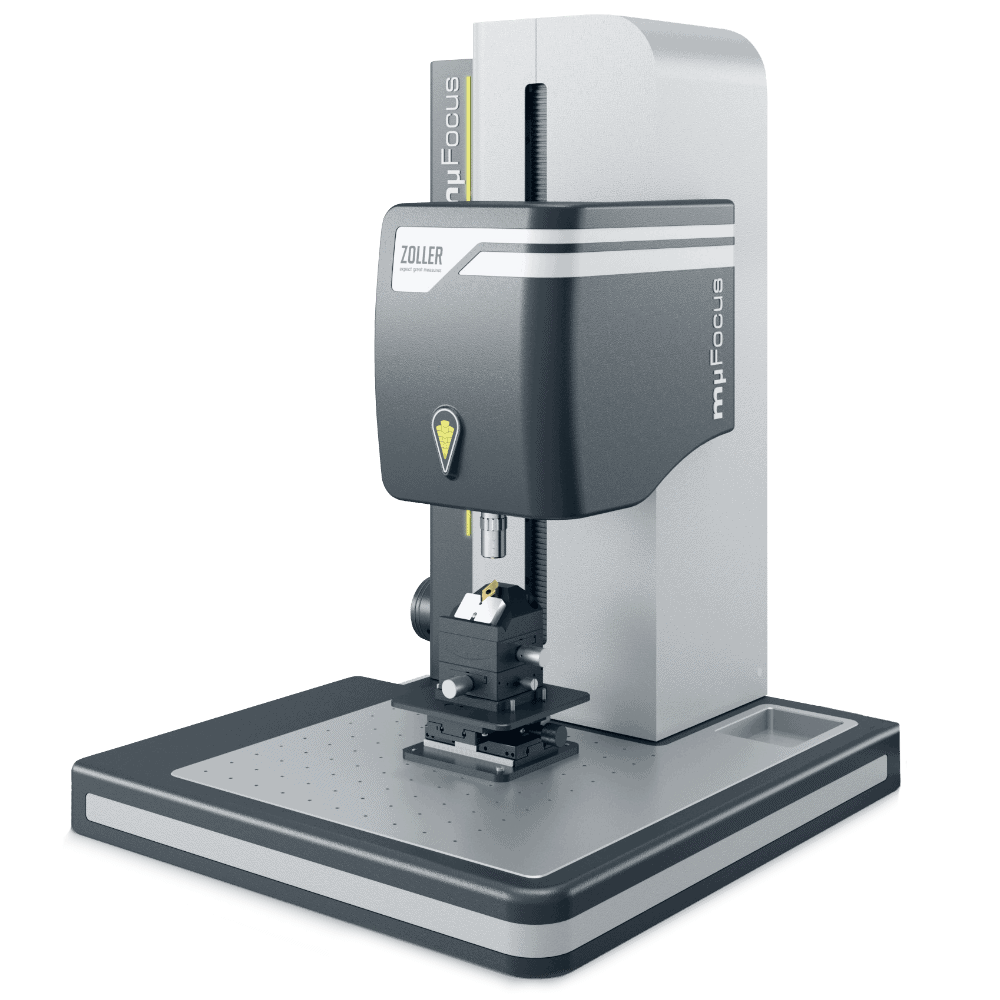

»mµFocus« analyzes cutting edge preparation and surface roughness without contact. Its resolution for roughness inspections is 0.1 µm.

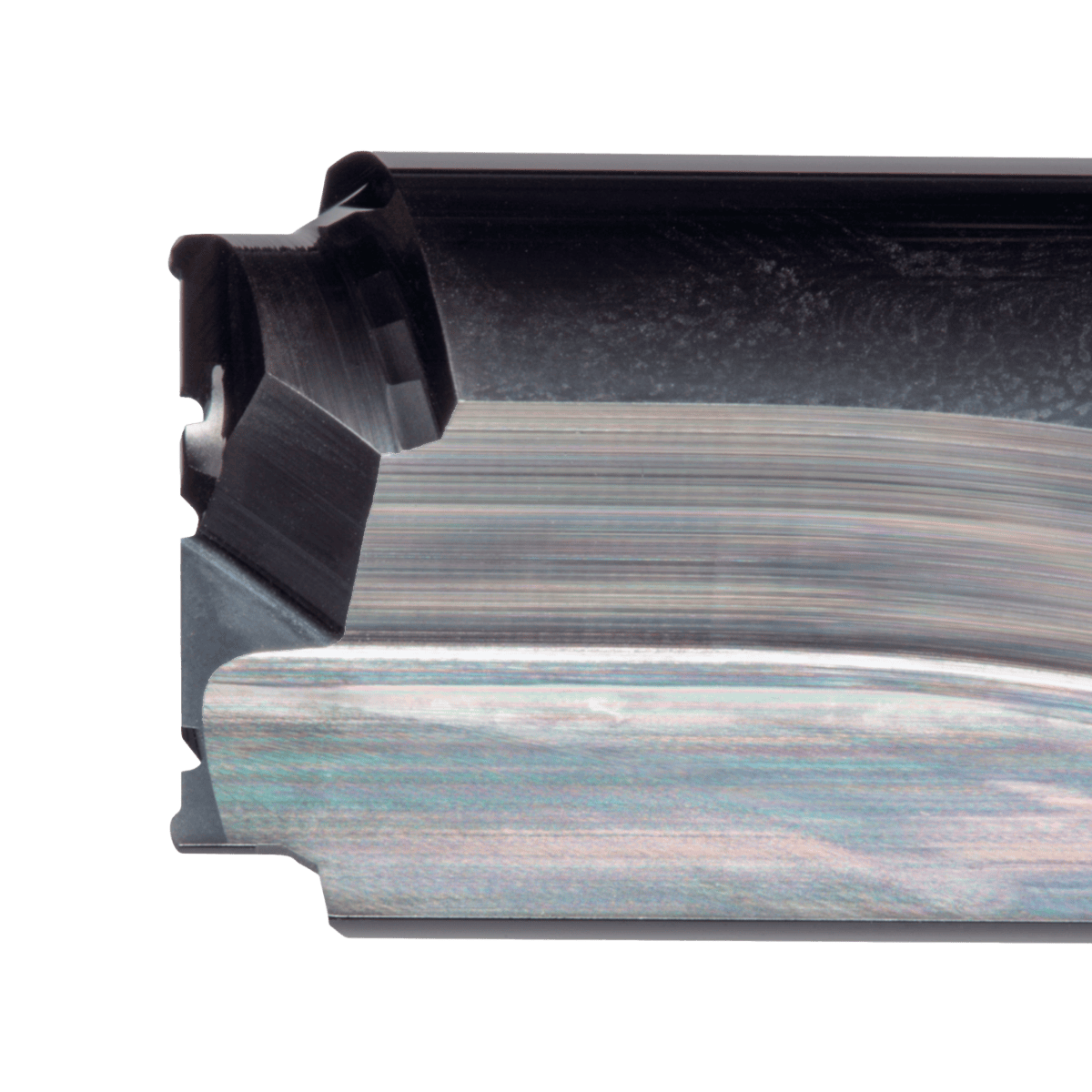

Cutting edge inspection in 3D

Analyze the cutting edge preparation and surface roughness of a tool without wasting time, directly in the grinding shop and with impressively accurate 3D visualizations.

»mµFocus« meets all the requirements for speed, precision and robustness that tool developers and manufacturers place on an inspection device. High-end design for the best tools in the world.

Arrange 1:1 expert meeting

Only one minute

Within around one minute, »mµFocus« captures all image data required for visualization in 3D. Short, precise measurement cycles for random samples and batches.