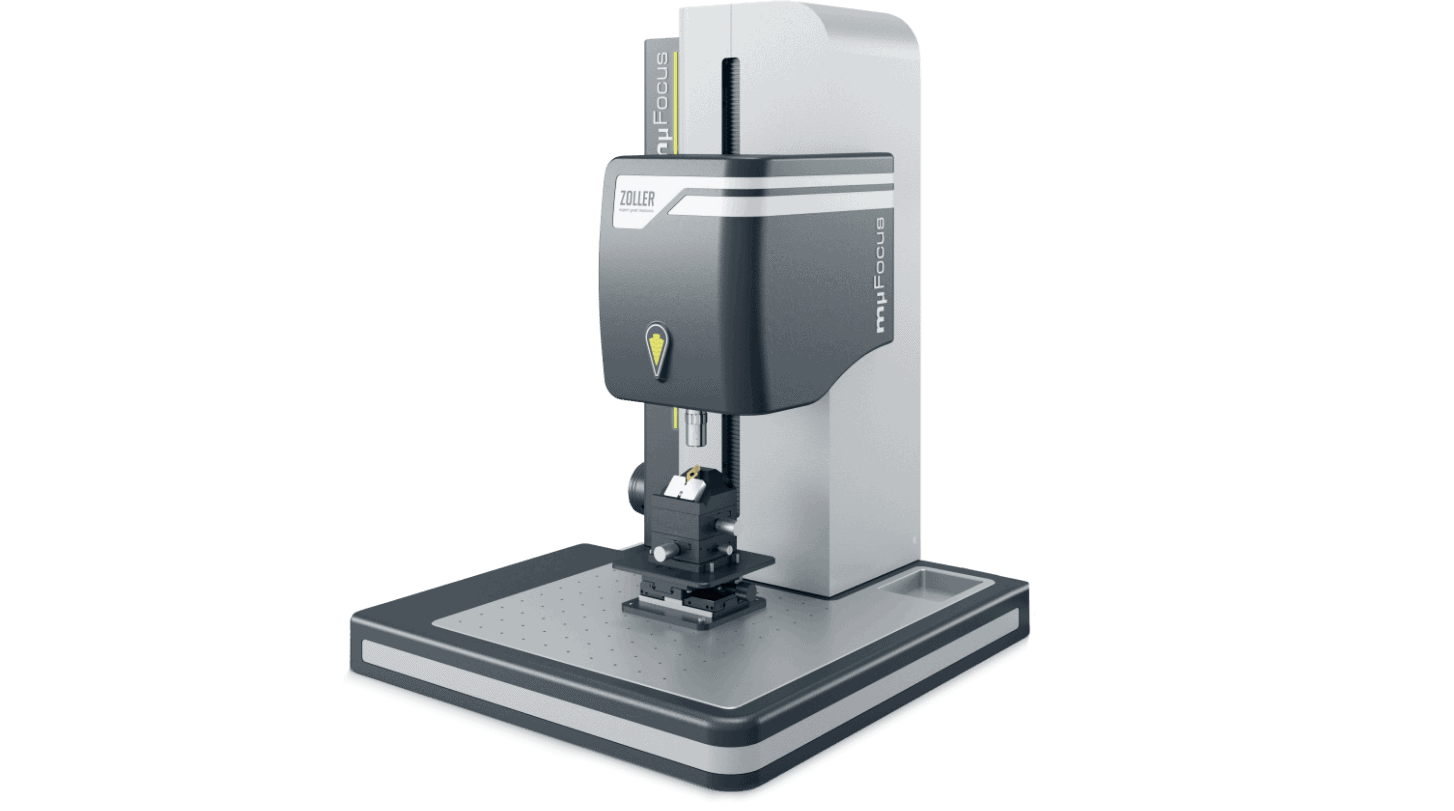

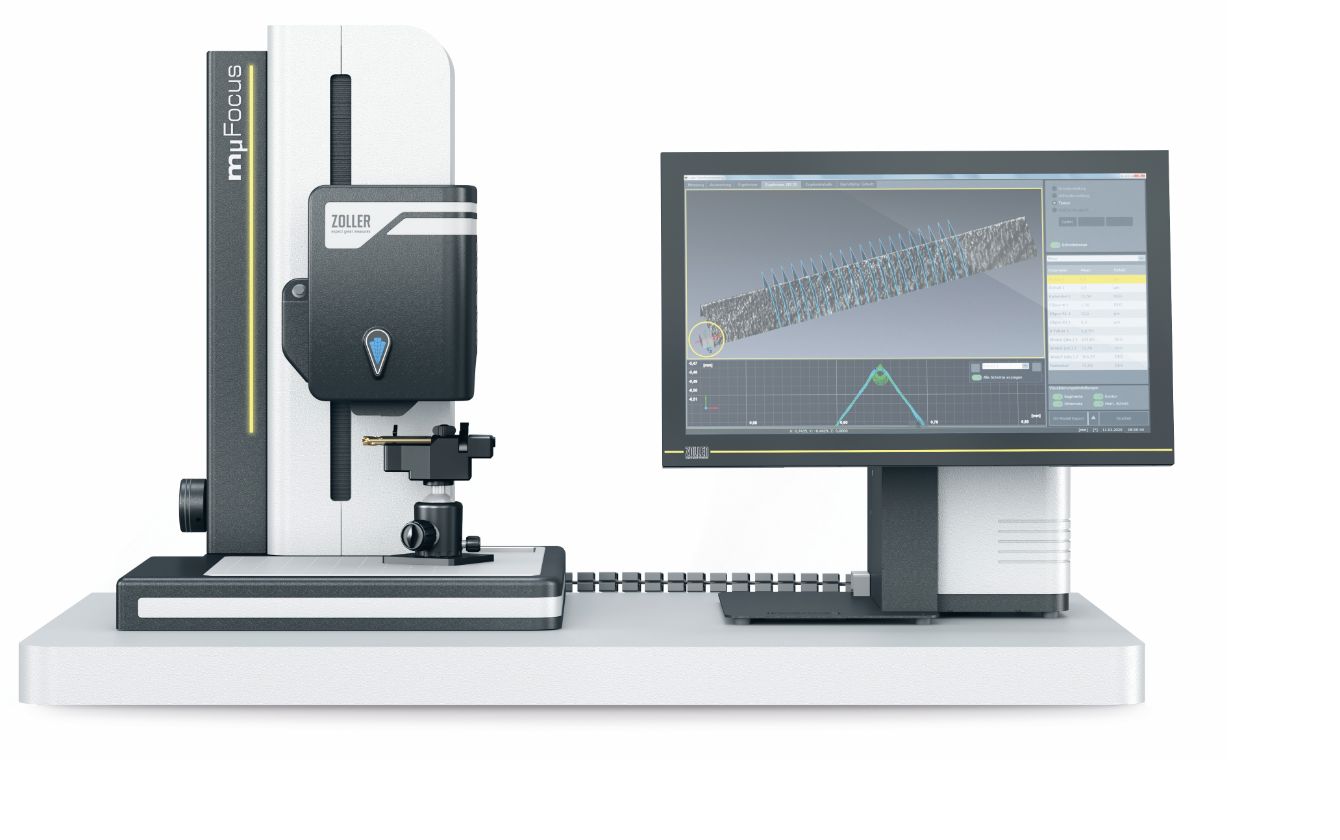

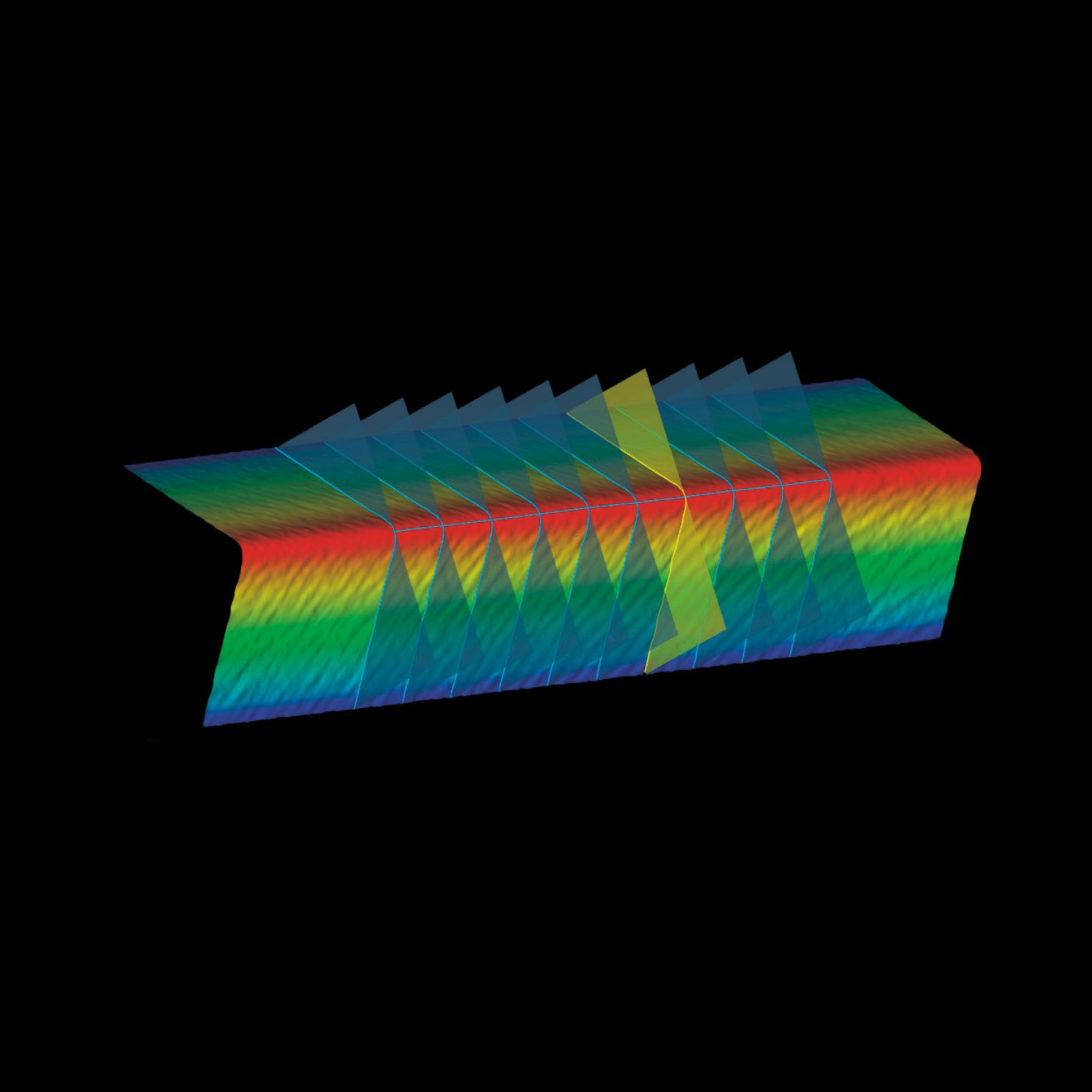

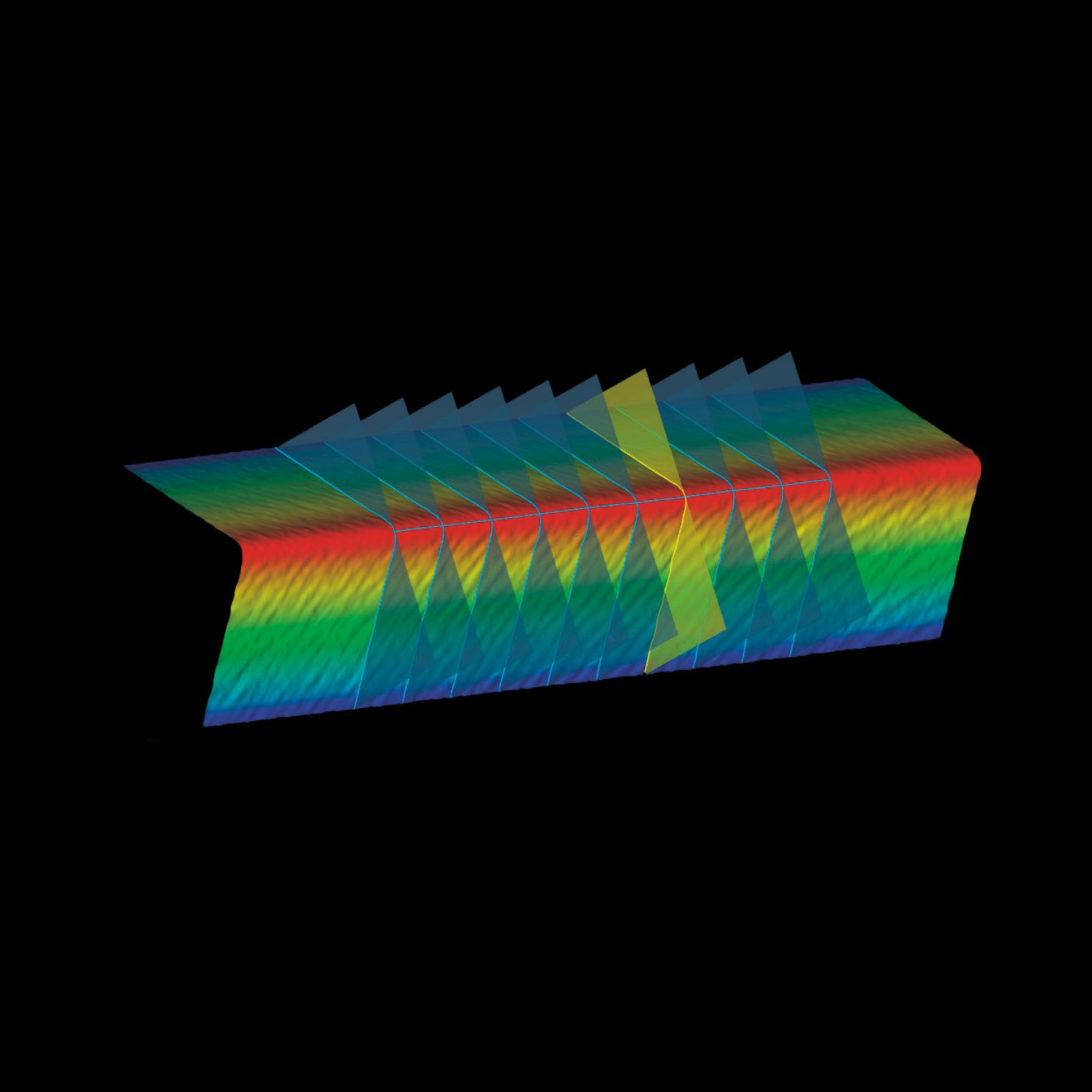

High-precision three-dimensional images

Calculated from many individual images, »mµFocus« displays the tool cutting edge high-precisely in 3D. You determine the level of detail via the number of images. You can display the measurement result topographically, in grayscale, as measurement curves or in tabular form according to DIN. This view on tool cutting edges is the richest in perspective.

High-precision three-dimensional images

Calculated from many individual images, »mµFocus« displays the tool cutting edge high-precisely in 3D. You determine the level of detail via the number of images. You can display the measurement result topographically, in grayscale, as measurement curves or in tabular form according to DIN. This view on tool cutting edges is the richest in perspective.

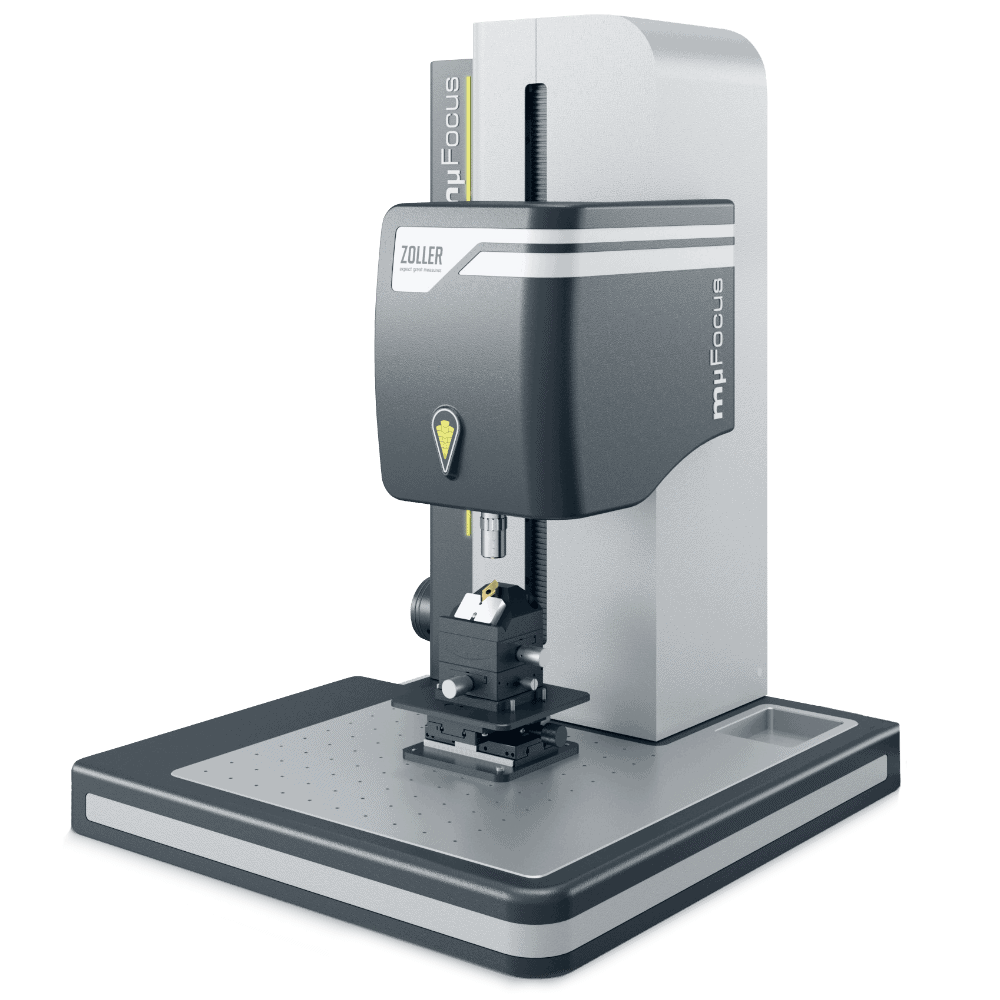

Display roughness with color-labeled topography

»mµFocus« visualizes the quality factor roughness by using easily distinguishable colour- labeling. Light and dark blue show depressions, yellow and red indicate elevations. The light blue line represents the measuring path. Grooves, for example, can be quickly identified with this color-labeling.

Display roughness with color-labeled topography

»mµFocus« visualizes the quality factor roughness by using easily distinguishable colour- labeling. Light and dark blue show depressions, yellow and red indicate elevations. The light blue line represents the measuring path. Grooves, for example, can be quickly identified with this color-labeling.

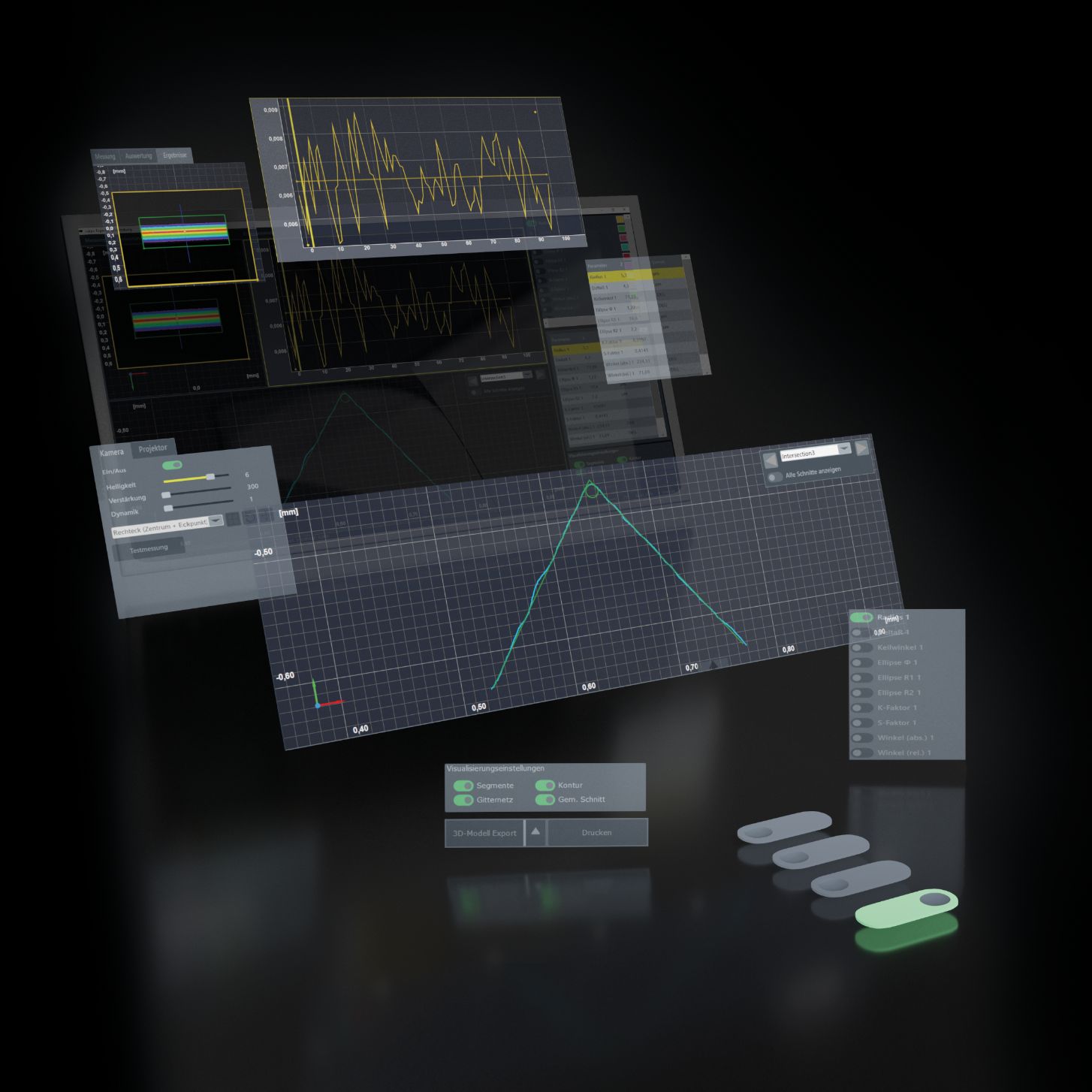

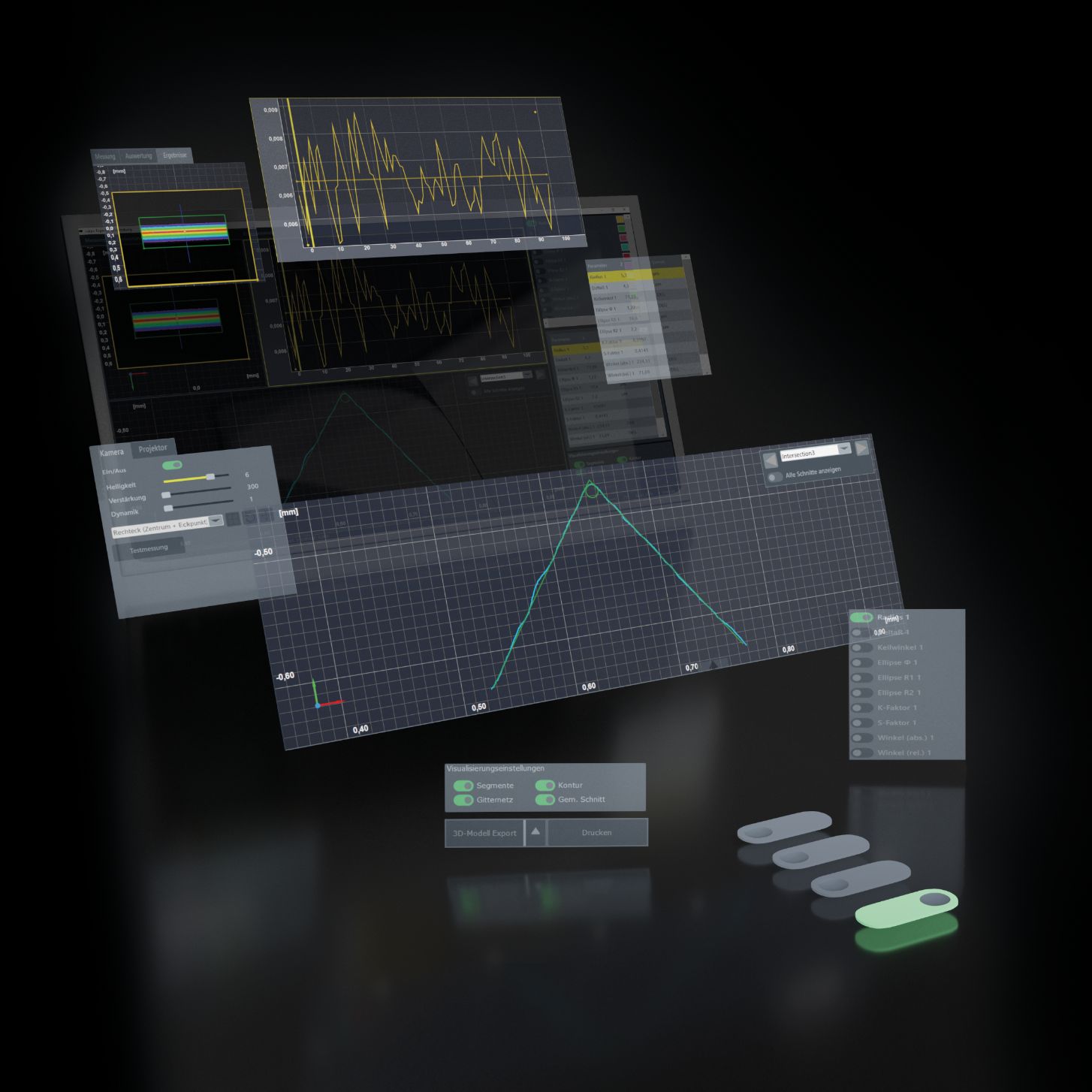

»pilot 4.0«: Perfection with image data

»pilot 4.0« supports you perfectly. Simple operation, clear icons for cutting edge shapes and fast navigation through the menu structure characterize this image processing software. It converts image data into meaningful diagrams and 3D visualizations. You will immediately recognize the unmistakable signature of your tool manufacturing.

»pilot 4.0«: Perfection with image data

»pilot 4.0« supports you perfectly. Simple operation, clear icons for cutting edge shapes and fast navigation through the menu structure characterize this image processing software. It converts image data into meaningful diagrams and 3D visualizations. You will immediately recognize the unmistakable signature of your tool manufacturing.