The Future for Every Production:

From CAM-To-Part to the Smart Factory

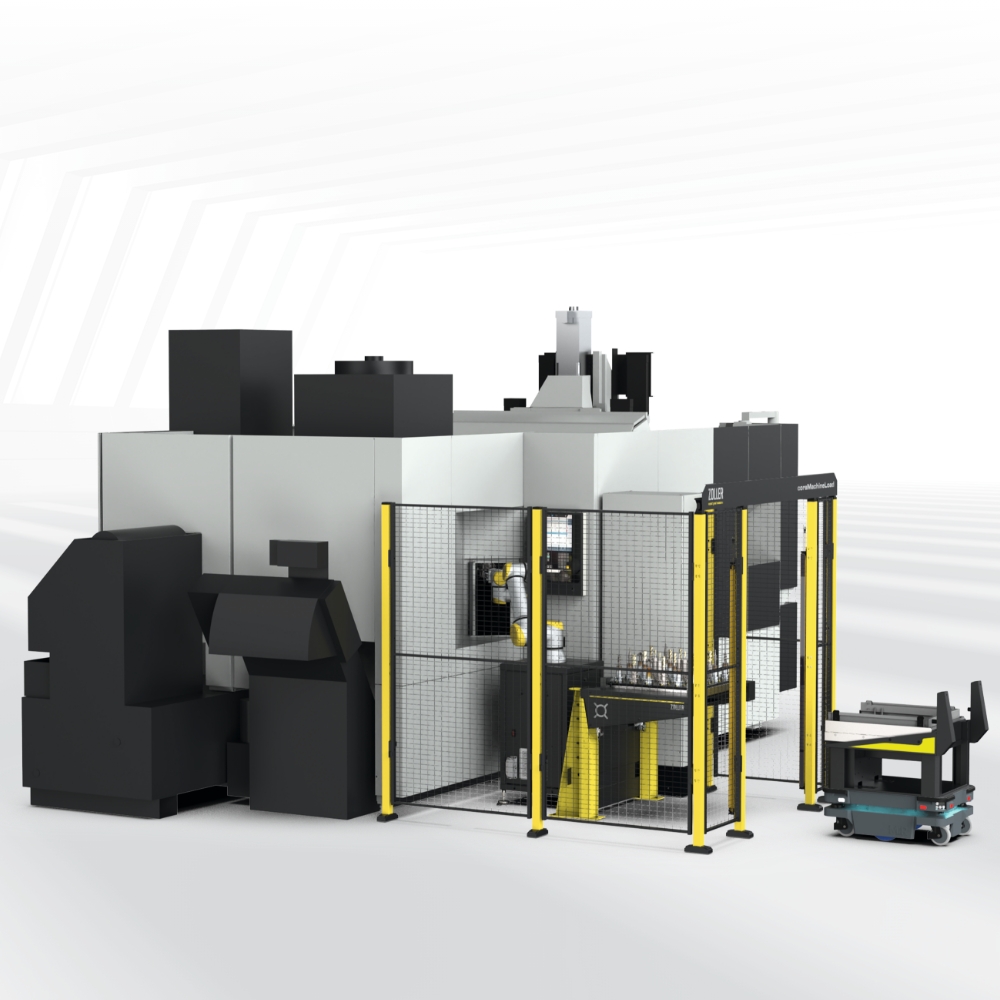

Find out at EMO 2025 how ZOLLER can help you digitize the process from the CAM system to the control of the CNC machine. We present the seven ZOLLER Solutions – including automation – and show where you can already use AI technology.

Experience in a real sample tool room how you can digitalize processes step by step with the ZOLLER Solutions and network them using tool data – from tool management to tool preparation and quality assurance. This is how digital CAM‑to‑part succeeds in every production process.

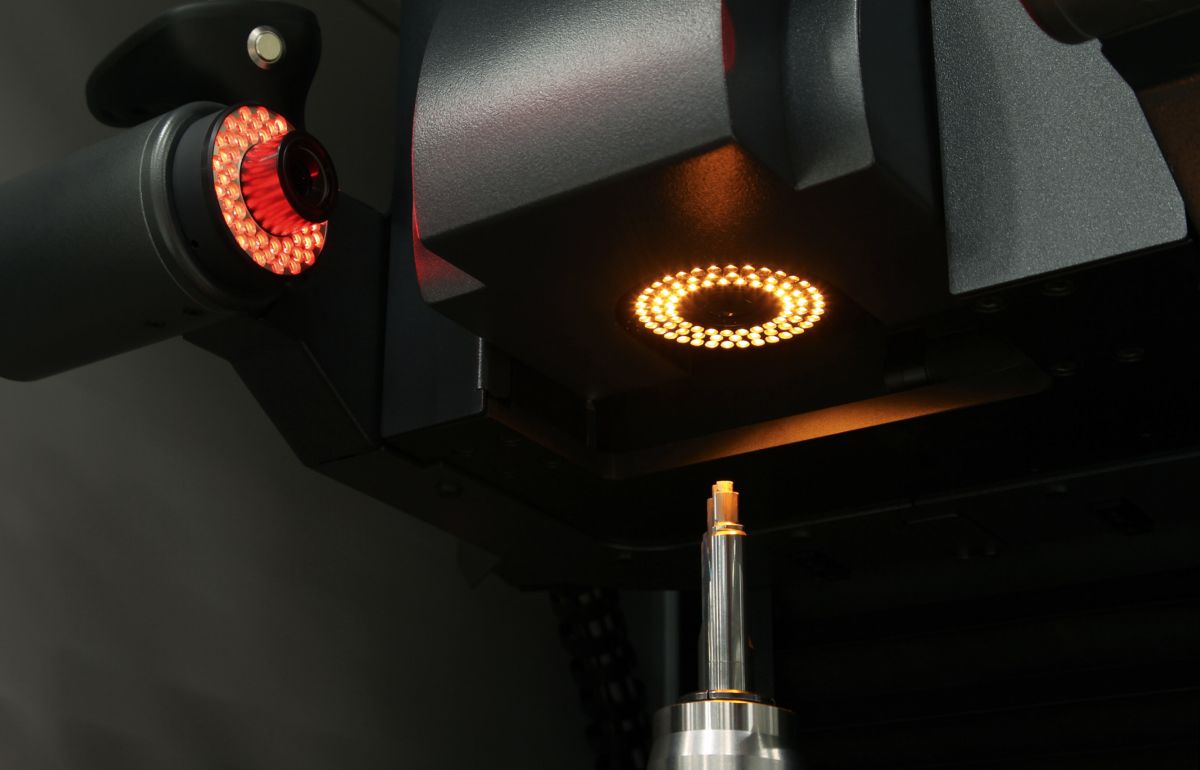

Our software innovation is called ZOLLER »zKI«. The AI-supported solution detects tool wear at the presetting and measuring machine and is simple to integrate.

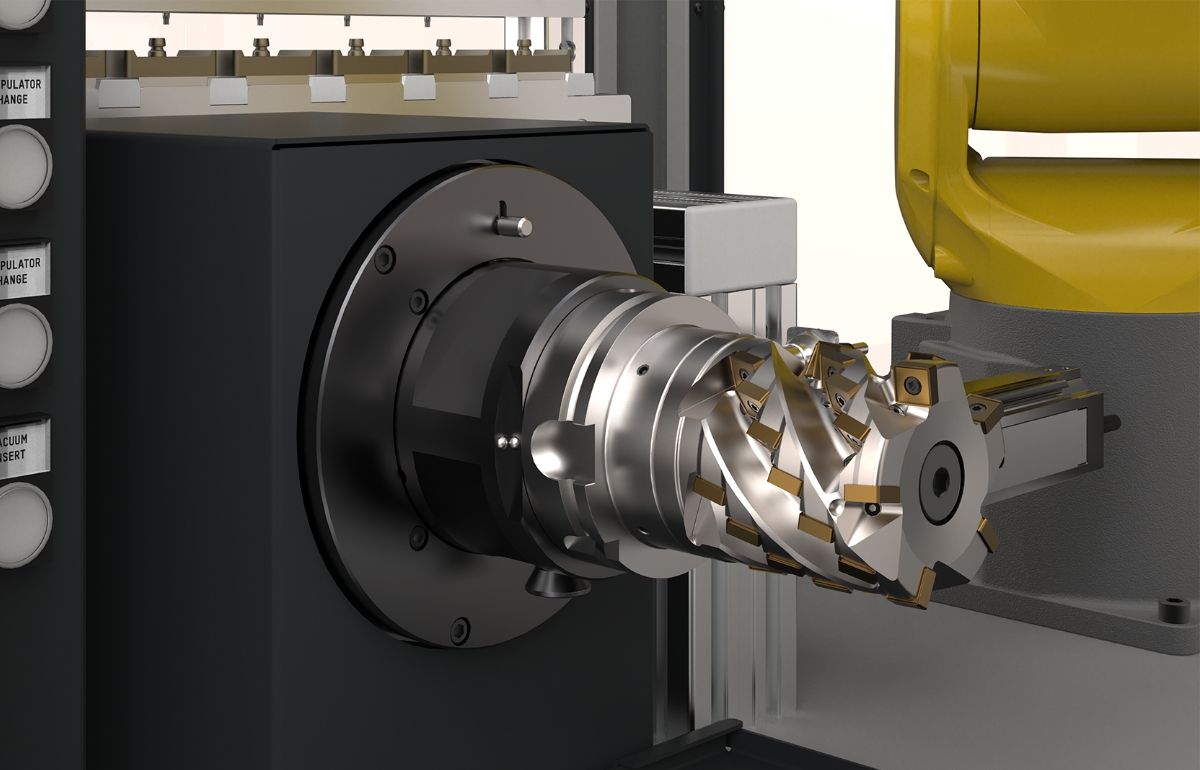

There are also new highlights in ZOLLER's automation portfolio. For example, the ZOLLER »micBox«. It specializes in the automated exchange and cutting edge replacement of indexable inserts. In addition, we will be showing other systems for efficient tool assembly.

With ZOLLER's modular principle, the transition to the Smart Factory is reliable and fast. This means you always manufacture economically and with an eye to the future.

Let's talk about it at EMO 2025. Hall 4, Booth C21.

Your Challenges – Our System!

Seven ZOLLER Solutions at the world's leading trade fair for production technology:

Get to know the unique advantages of an integrated, step-by-step combinable system.

Start with a solution - Enter a system.

Modular

Experience the performance of ZOLLER Solutions at the trade fair and move your company forward.

Economical

Discover the effectiveness of our transformative technologies.

Future-oriented

Network with ZOLLER industry experts and colleagues to realize new projects together.