Top products

Even with a shortage of skilled workers, ZOLLER allows you to set up faster, always measure precisely thanks to simple operation, manufacture with up-to-date data and reliably ensure quality.

- Software That Grows With You

TMS Tool Management Solutions

Manage your individual component data such as cutting material and weights in a simple and detailed way. Thanks to the tool parts list, drawing and 3D model, you are guaranteed to assemble your tools correctly directly at the workplace on the workbench. ZOLLER offers interfaces from the TMS Tool Management Solutions to all common CAM and simulation systems.

- Software That Grows With You

TMS Tool Management Solutions

Manage your individual component data such as cutting material and weights in a simple and detailed way. Thanks to the tool parts list, drawing and 3D model, you are guaranteed to assemble your tools correctly directly at the workplace on the workbench. ZOLLER offers interfaces from the TMS Tool Management Solutions to all common CAM and simulation systems.

- Efficient Tool Storage

Smart Cabinets

Intelligent store and management solutions for grinding wheels, tools, components and accessories. Perfectly matched to the ZOLLER TMS Tool Management Solutions software.

- Efficient Tool Storage

Smart Cabinets

Intelligent store and management solutions for grinding wheels, tools, components and accessories. Perfectly matched to the ZOLLER TMS Tool Management Solutions software.

- Data transfer

»zidCode«

The technology ensures safe data transfer to the CNC machine »zidCode« from ZOLLER. At all stations, the tool data is transferred via barcodes, QR codes or DataMatrix codes, optionally using the technology »idChip« with handheld scanners in connection with the tool identification »zidCode« entered and transferred, and managed centrally in the z.One database.

- Data transfer

»zidCode«

The technology ensures safe data transfer to the CNC machine »zidCode« from ZOLLER. At all stations, the tool data is transferred via barcodes, QR codes or DataMatrix codes, optionally using the technology »idChip« with handheld scanners in connection with the tool identification »zidCode« entered and transferred, and managed centrally in the z.One database.

- Shrinking Technology

»redomatic«

With one »redomatic 400« or »redomatic 600« from ZOLLER, you will produce more effectively with your multi-spindle machines and in your automated high volume manufacturing. Because with »redomatic« you can be sure that the tool lengths are always set correctly. The shrink fit process developed by ZOLLER with the adjusting adapter is »masterPiece« is both fast and simple.

- Shrinking Technology

»redomatic«

With one »redomatic 400« or »redomatic 600« from ZOLLER, you will produce more effectively with your multi-spindle machines and in your automated high volume manufacturing. Because with »redomatic« you can be sure that the tool lengths are always set correctly. The shrink fit process developed by ZOLLER with the adjusting adapter is »masterPiece« is both fast and simple.

- Shrinking Technology

»powerShrink«

Shrink-fit and unshrink tools in record time while saving energy and protecting the chuck: You get all these benefits with the inductive shrink-fit system »powerShrink«. When developing this device, ZOLLER placed a high value on maximum energy efficiency as well as a fast and reliable shrinking process – for more efficiency in your production.

- Shrinking Technology

»powerShrink«

Shrink-fit and unshrink tools in record time while saving energy and protecting the chuck: You get all these benefits with the inductive shrink-fit system »powerShrink«. When developing this device, ZOLLER placed a high value on maximum energy efficiency as well as a fast and reliable shrinking process – for more efficiency in your production.

- Balancing Technology

»toolBalancer«

»toolBalancer« ensures the radial run-out of grinding wheels and rotating tools with an accuracy of < 0.4 gmm.

Balancing is a quality-determining factor in parts production and tool manufacturers. Surfaces and cutting edges benefit from precisely balanced tools and grinding wheels.

In addition, balancing protects the high-speed spindles of your CNC machine. Even low unbalances can put a massive strain on the spindle mechanics.

- Balancing Technology

»toolBalancer«

»toolBalancer« ensures the radial run-out of grinding wheels and rotating tools with an accuracy of < 0.4 gmm.

Balancing is a quality-determining factor in parts production and tool manufacturers. Surfaces and cutting edges benefit from precisely balanced tools and grinding wheels.

In addition, balancing protects the high-speed spindles of your CNC machine. Even low unbalances can put a massive strain on the spindle mechanics.

- Presetting & Measuring

»smile« and »venturion«

With »smile 420« start your professional setting and measurement of standard tools. »venturion 450« is a premium class presetting and measuring machine.

What these two ZOLLER Solutions have in common: With simple, µm-precise measurements, they shorten setup times and increase tool life.

The scalable annual savings potential per shift and CNC machine lies at 15,000 euros.

- Presetting & Measuring

»smile« and »venturion«

With »smile 420« start your professional setting and measurement of standard tools. »venturion 450« is a premium class presetting and measuring machine.

What these two ZOLLER Solutions have in common: With simple, µm-precise measurements, they shorten setup times and increase tool life.

The scalable annual savings potential per shift and CNC machine lies at 15,000 euros.

- Automation Solutions

»coraMeasure LG«

»coraMeasure LG« measures tools in an automated manner using a room gantry robot and an intelligent pallet system for the delivery of the tools to be measured. »coraMeasureLG« can be seamlessly integrated into existing ZOLLER devices for maximum performance and minimum downtime.

- Automation Solutions

»coraMeasure LG«

»coraMeasure LG« measures tools in an automated manner using a room gantry robot and an intelligent pallet system for the delivery of the tools to be measured. »coraMeasureLG« can be seamlessly integrated into existing ZOLLER devices for maximum performance and minimum downtime.

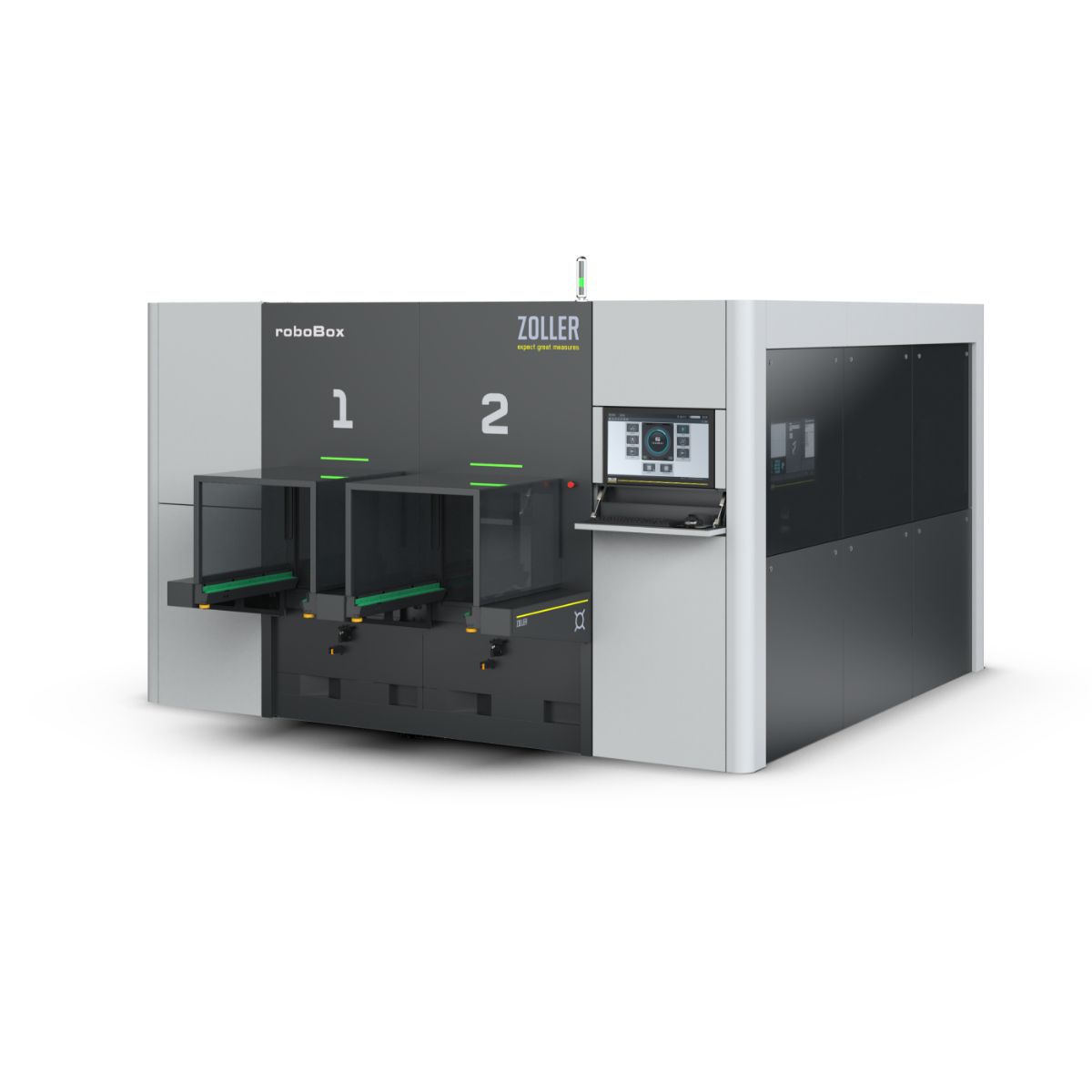

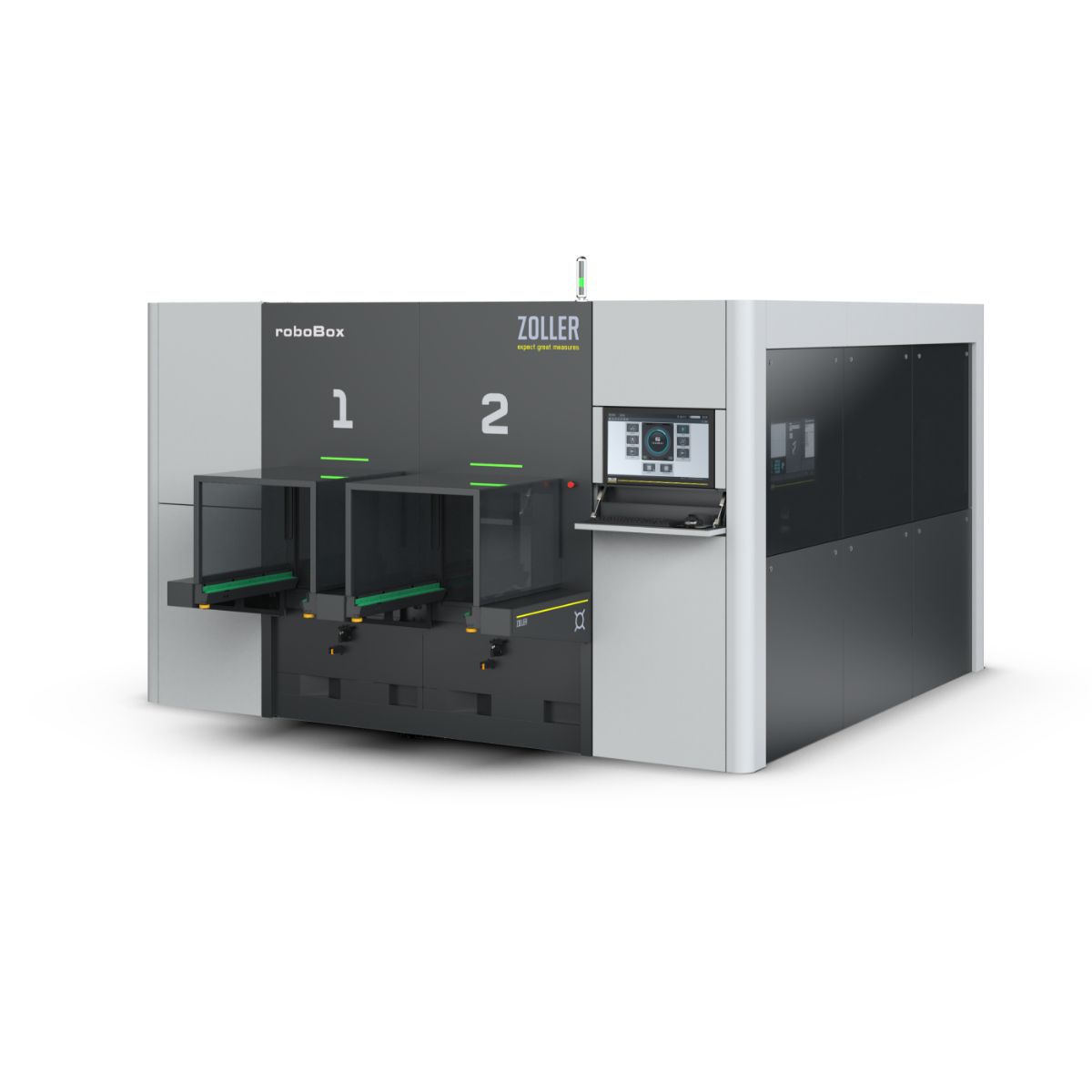

- Automation Solutions

»roboBox«

»roboBox« automates processes such as the assembly, measuring, setting and shrinking of tools. In connection, it transfers the tools directly to »coraLogistic«.

- Automation Solutions

»roboBox«

»roboBox« automates processes such as the assembly, measuring, setting and shrinking of tools. In connection, it transfers the tools directly to »coraLogistic«.

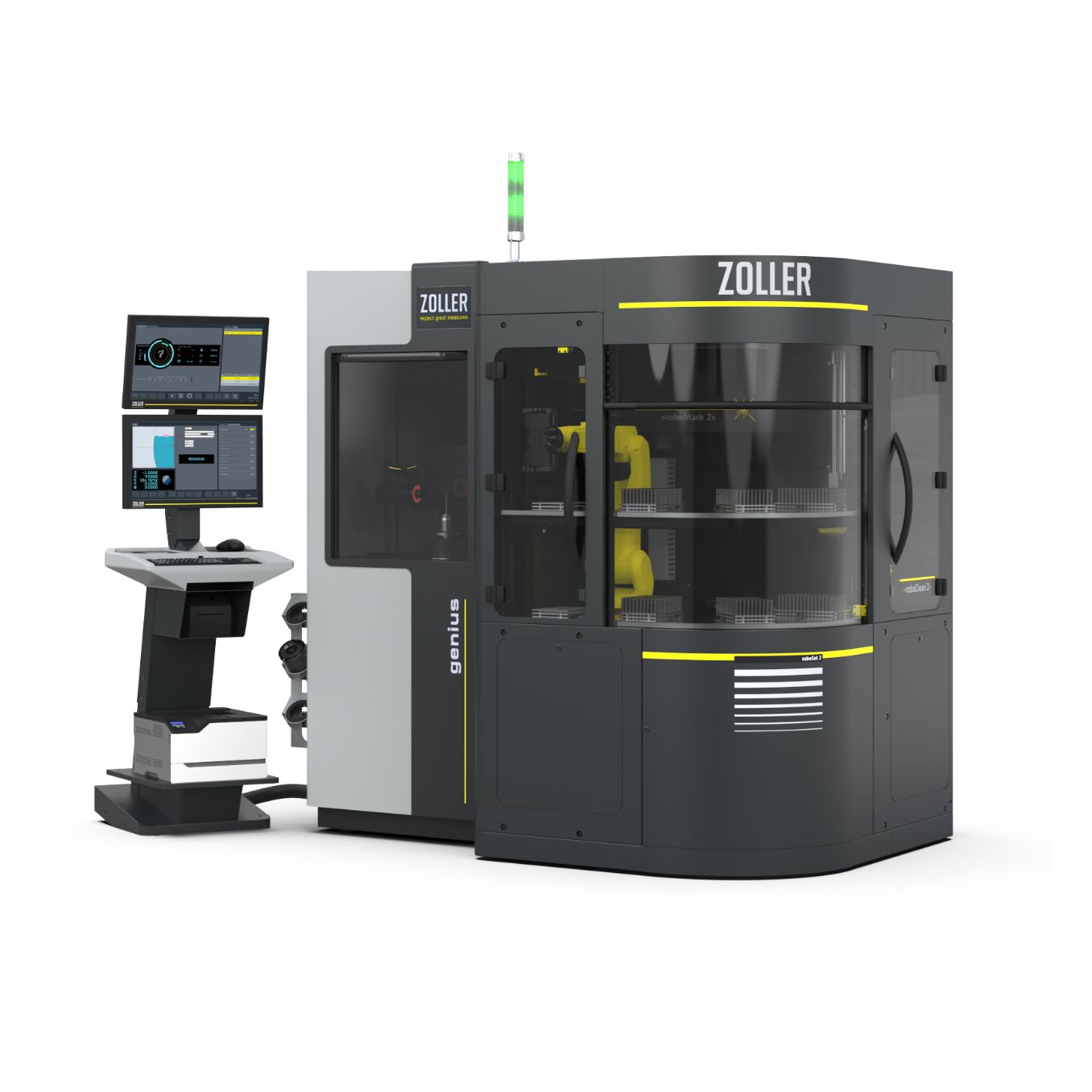

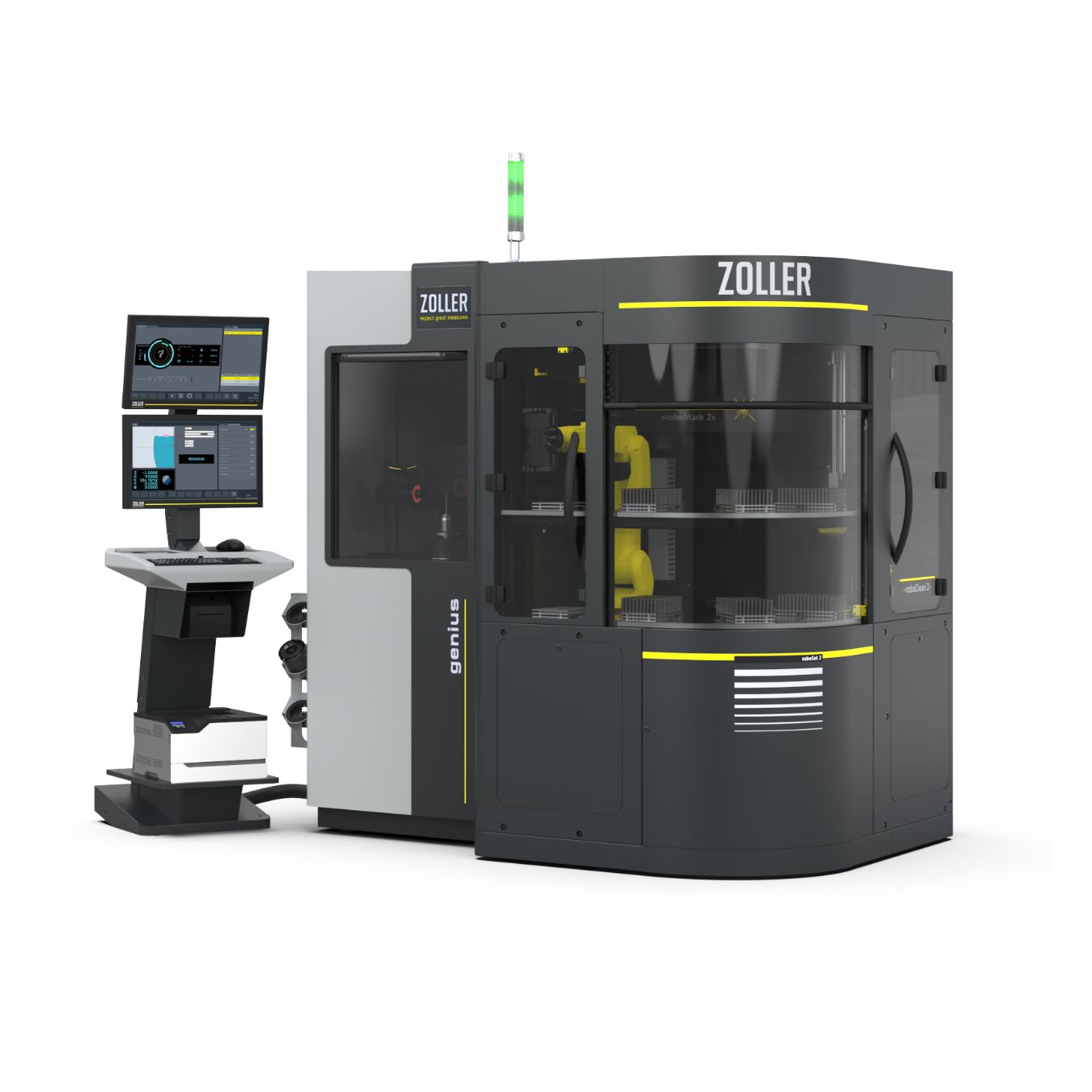

Tool Inspection

»genius«

This universal measuring machine provides comprehensive proof of quality for every cutting tool on more than 100 parameters. »genius« performs non-contact inspections in 2D and 3D with high precision. From quick checks of individual criteria to fully automatic and user-independent complete control, you have everything combined in one measuring machine.

In the execution »titan« you additionally check the cutting edge preparation without contact »« for complete, meaningful documentation of your tools.

Tool Inspection

»genius«

This universal measuring machine provides comprehensive proof of quality for every cutting tool on more than 100 parameters. »genius« performs non-contact inspections in 2D and 3D with high precision. From quick checks of individual criteria to fully automatic and user-independent complete control, you have everything combined in one measuring machine.

In the execution »titan« you additionally check the cutting edge preparation without contact »« for complete, meaningful documentation of your tools.

Automation

»roboSet 2«

This automation solution for tool inspection ensures high throughput in a small surface area. Coupled to your ZOLLER Universal measuring machine »titan«, »threadCheck« or »genius«takes over »roboSet 2« handles the tool handling of large and small batches.

The potential to reduce personnel costs for tool inspection lies at up to 83 %.

Automation

»roboSet 2«

This automation solution for tool inspection ensures high throughput in a small surface area. Coupled to your ZOLLER Universal measuring machine »titan«, »threadCheck« or »genius«takes over »roboSet 2« handles the tool handling of large and small batches.

The potential to reduce personnel costs for tool inspection lies at up to 83 %.

- Process-Oriented Measuring

»pomBasic«

ZOLLER »pomBasic« and »pomBasicMicro« measure and check tools in seconds at goods receipt and in the grinding shop. The simple to operate universal devices enter over 70 parameters.

»pomBasic« is perfect for tools from 3 mm diameter. For micro tools from 0.2 mm diameter is »pomBasicMicro« Your expert.

- Process-Oriented Measuring

»pomBasic«

ZOLLER »pomBasic« and »pomBasicMicro« measure and check tools in seconds at goods receipt and in the grinding shop. The simple to operate universal devices enter over 70 parameters.

»pomBasic« is perfect for tools from 3 mm diameter. For micro tools from 0.2 mm diameter is »pomBasicMicro« Your expert.

- Tool Inspection on Hob Cutters

»hobCheck«

The quantum leap in the complete control of hob cutters – »hobCheck« opens up unprecedented options for the fully automatic, efficient and complete measurement of milling cutters, including large sizes.

- Tool Inspection on Hob Cutters

»hobCheck«

The quantum leap in the complete control of hob cutters – »hobCheck« opens up unprecedented options for the fully automatic, efficient and complete measurement of milling cutters, including large sizes.

- Process-Oriented Measurement of Cutting Edge Preparation

»mμFocus«

With »mµFocus« you have a high-end device that can be used close to the process and can create exact 3D images of the surface roughness in addition to cutting edge preparation.

- Process-Oriented Measurement of Cutting Edge Preparation

»mμFocus«

With »mµFocus« you have a high-end device that can be used close to the process and can create exact 3D images of the surface roughness in addition to cutting edge preparation.