Reduce Costs, Ensure Quality with the Smart Setup Process from ZOLLER

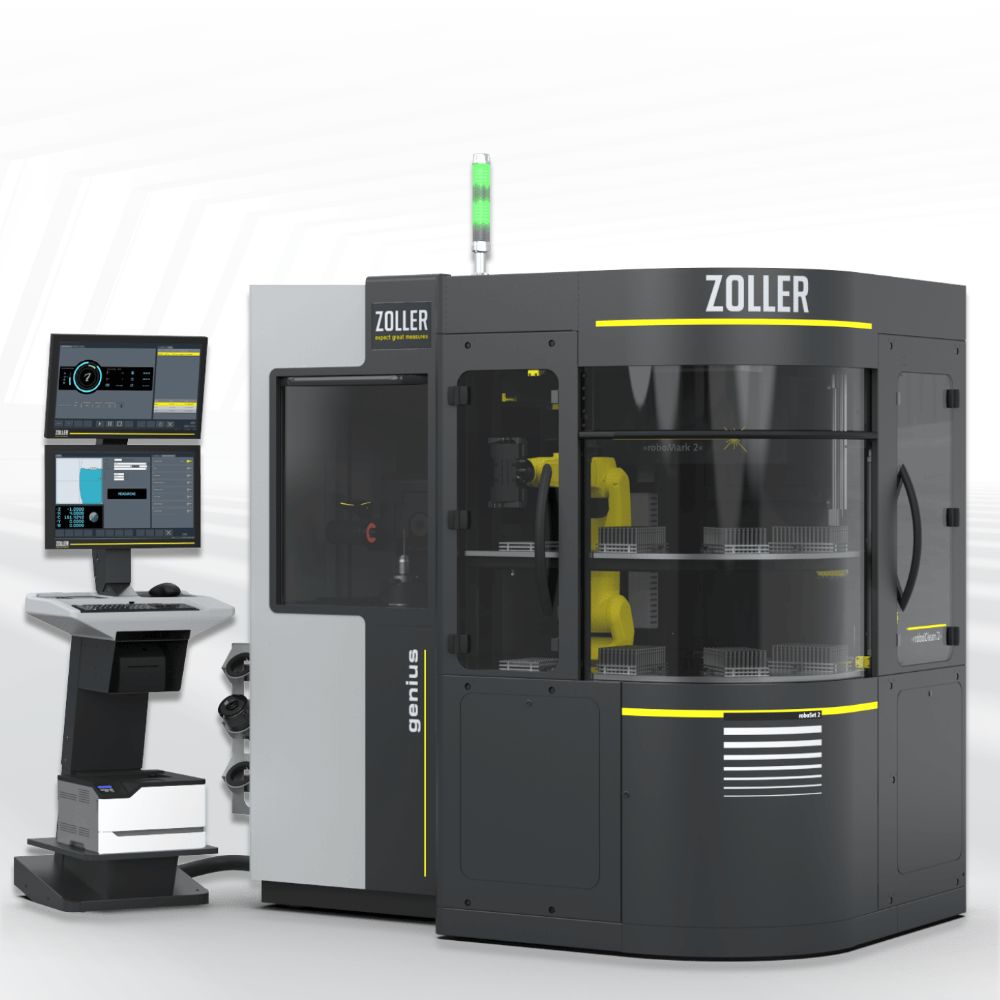

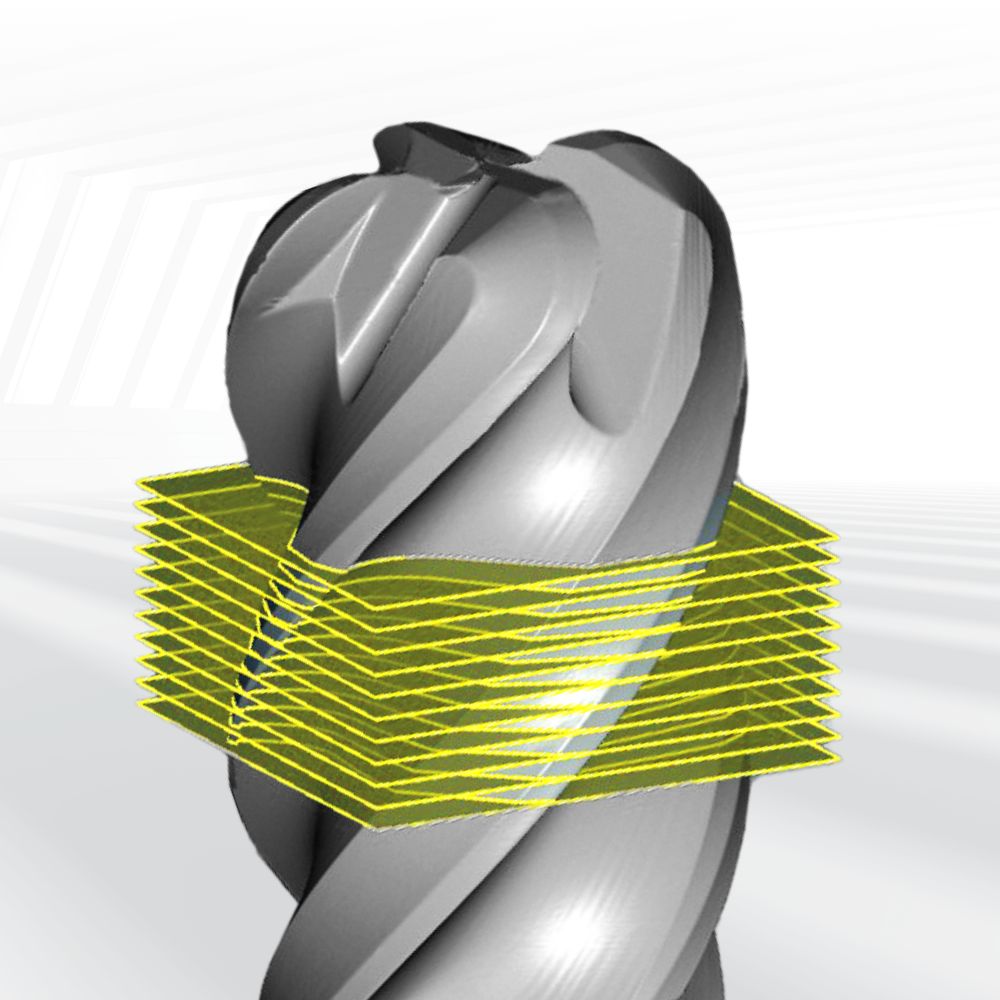

Act efficiently, and manufacture reliably regardless of the shortage of skilled workers: With ZOLLER, you can quickly and safely switch to a smart set-up process for grinding wheels. Five steps are all it takes: storage, balancing, measuring, automated data transfer to the grinding machine and in-process tool inspection directly at the grinding machine.

Your benefits: lower costs, shorter setup times, longer service life for grinding wheels, higher process reliability and repeatible high tool quality in every batch.

At GrindingHub, we showed 28 ZOLLER solutions for measuring and inspection as well as the smart setup process all the way to automation.

Discover the new ZOLLER Solutions in the field of 3D tool digitization and measurement of micro tools.

Get to know the Advantages of a Globally Unique System

ZOLLER Solutions at the international trade fair for grinding technology in Stuttgart:

Innovative products, digitalized processes and efficiency made by ZOLLER.

ZOLLER offers you a solution system with which you can take your production step by step into the future.

Identify the efficiency leaks in your production process and get to know the ZOLLER Solutions.

At ZOLLER, everything comes from a single source and is perfectly coordinated: Software, Tool storage, Presetting and measuring machines, Inspection, Data handling, Automation.

Thank you for visiting GrindingHub 2024

Start with a solution - Enter a system: Come and visit us again - at our Smart Factory in Pleidelsheim or at one of our branches - and at other events!

Thank you for visiting GrindingHub 2024

Start with a solution - Enter a system: Come and visit us again - at our Smart Factory in Pleidelsheim or at one of our branches - and at other events!