Top products

Even with a shortage of skilled workers, ZOLLER enables faster setups, consistent and precise tool measurements, and ensures that you can manufacture with up-to-date data and reliable quality.

Discover the unique ZOLLER Solutions system.

- Tool inspection

»smileCheck«

With the »smileCheck« you can inspect not only tools but also grinding wheels in incident and transmitted light. Enhanced by the optional CNC control, µm-precise inspections are possible at the touch of a button.

- Tool inspection

»smileCheck«

With the »smileCheck« you can inspect not only tools but also grinding wheels in incident and transmitted light. Enhanced by the optional CNC control, µm-precise inspections are possible at the touch of a button.

- Tool inspection

»smartCheck«

The premium class for the complete inspection of grinding wheels and grinding wheel packs as well as for quality assurance when grinding and regrinding all types of tools. Thanks to the swivelling optics carrier, you can also inspect threading tools with »smartCheck«.

- Tool inspection

»smartCheck«

The premium class for the complete inspection of grinding wheels and grinding wheel packs as well as for quality assurance when grinding and regrinding all types of tools. Thanks to the swivelling optics carrier, you can also inspect threading tools with »smartCheck«.

- Process-oriented measurement

»pomBasic« and »pomBasicMicro«

The ZOLLER »pomBasic« and »pomBasicMicro« measure and check tools directly in the grinding shop in a matter of seconds. The easy‑to‑use universal devices record over 70 parameters.

»pomBasic« is perfect for tools from 3 mm diameter. For micro tools from 0.2 mm diameter »pomBasicMicro« is your expert.

- Process-oriented measurement

»pomBasic« and »pomBasicMicro«

The ZOLLER »pomBasic« and »pomBasicMicro« measure and check tools directly in the grinding shop in a matter of seconds. The easy‑to‑use universal devices record over 70 parameters.

»pomBasic« is perfect for tools from 3 mm diameter. For micro tools from 0.2 mm diameter »pomBasicMicro« is your expert.

- Tool inspection on hob cutters

»hobCheck«

The quantum leap in the complete inspection of hob cutters – »hobCheck« opens up unprecedented possibilities for fully automatic, efficient and complete measurement of hob cutters, even large ones.

- Tool inspection on hob cutters

»hobCheck«

The quantum leap in the complete inspection of hob cutters – »hobCheck« opens up unprecedented possibilities for fully automatic, efficient and complete measurement of hob cutters, even large ones.

- Process-oriented measurement of the cutting edge preparation

»mμFocus« and »pomSkpGo«

»pomSkpGo« is a compact, mobile device with which you can measure the cutting edge preparation in a process-oriented manner.

With »mµFocus« you have a high-end device that can be used close to the grinding machine and that can also create precise 3D images of surface roughness in addition to cutting edge preparation.

- Process-oriented measurement of the cutting edge preparation

»mμFocus« and »pomSkpGo«

»pomSkpGo« is a compact, mobile device with which you can measure the cutting edge preparation in a process-oriented manner.

With »mµFocus« you have a high-end device that can be used close to the grinding machine and that can also create precise 3D images of surface roughness in addition to cutting edge preparation.

Tool inspection

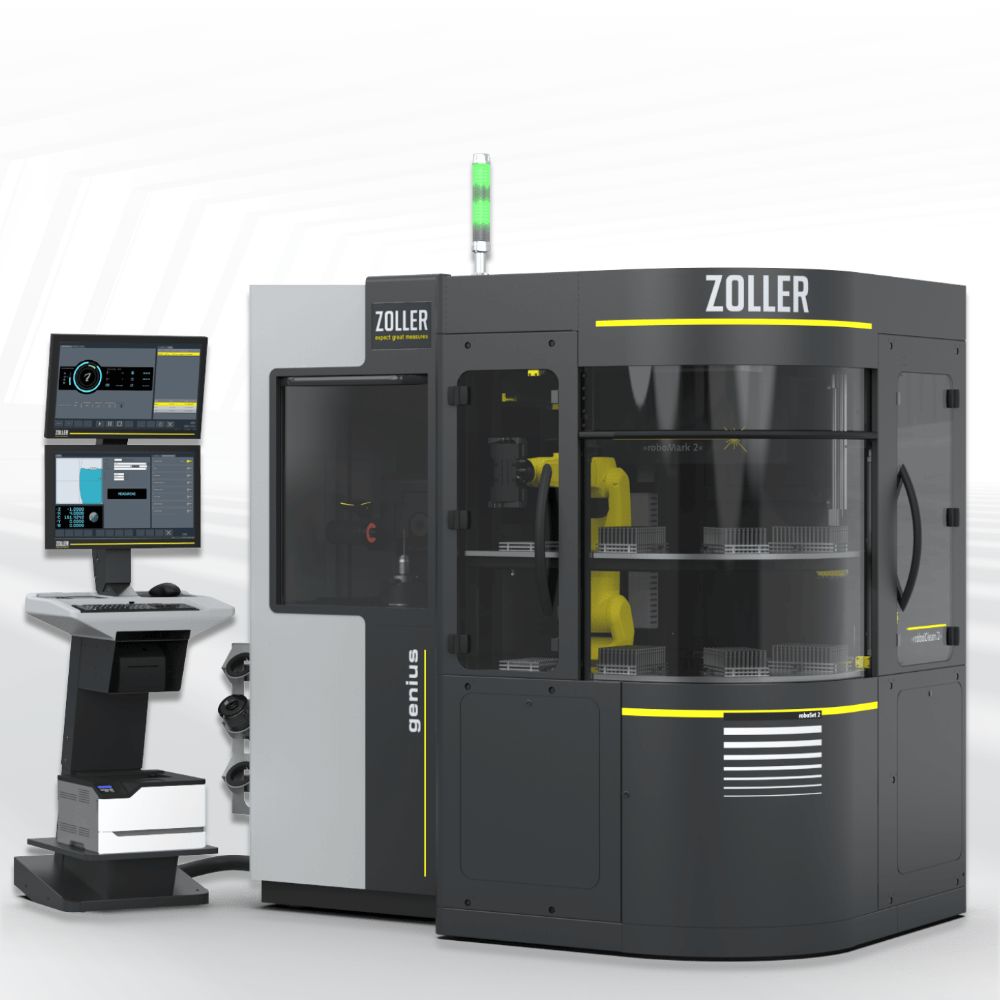

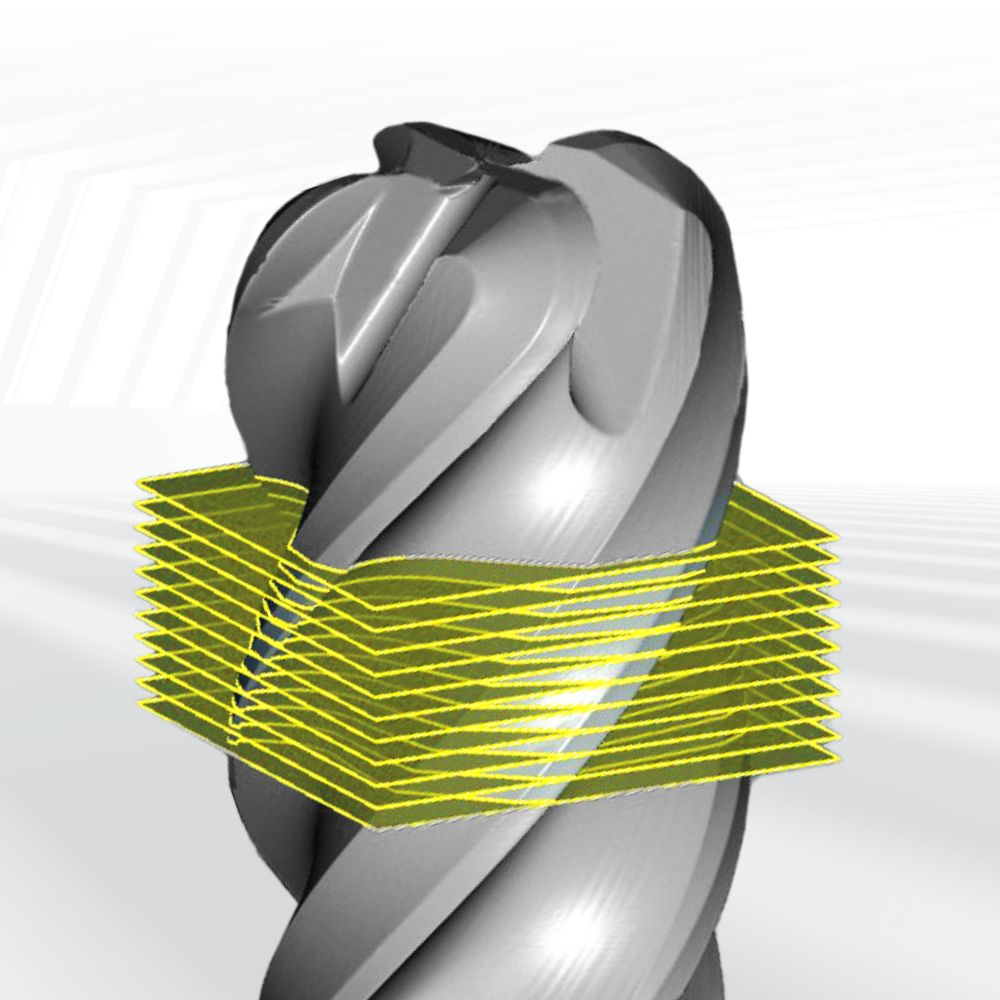

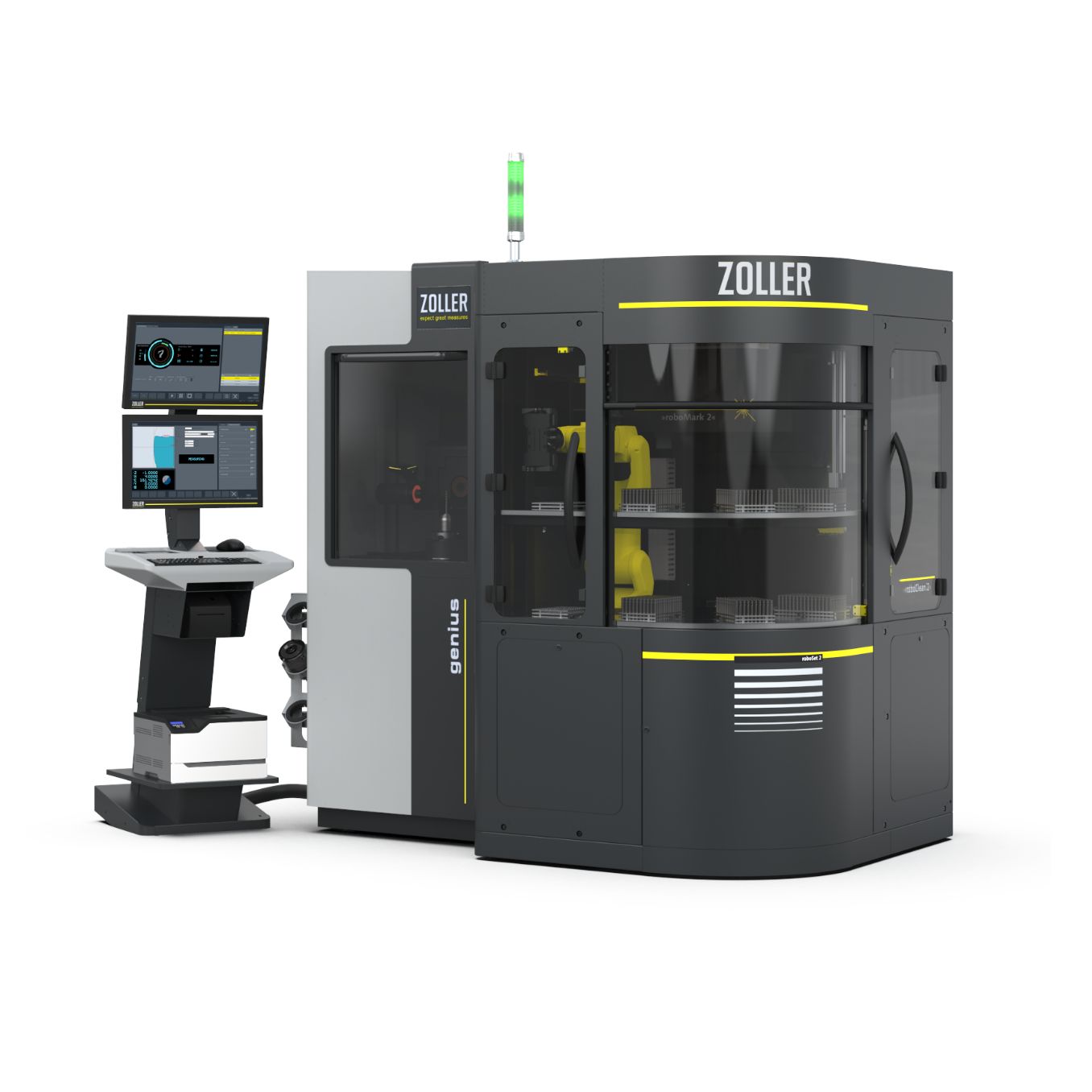

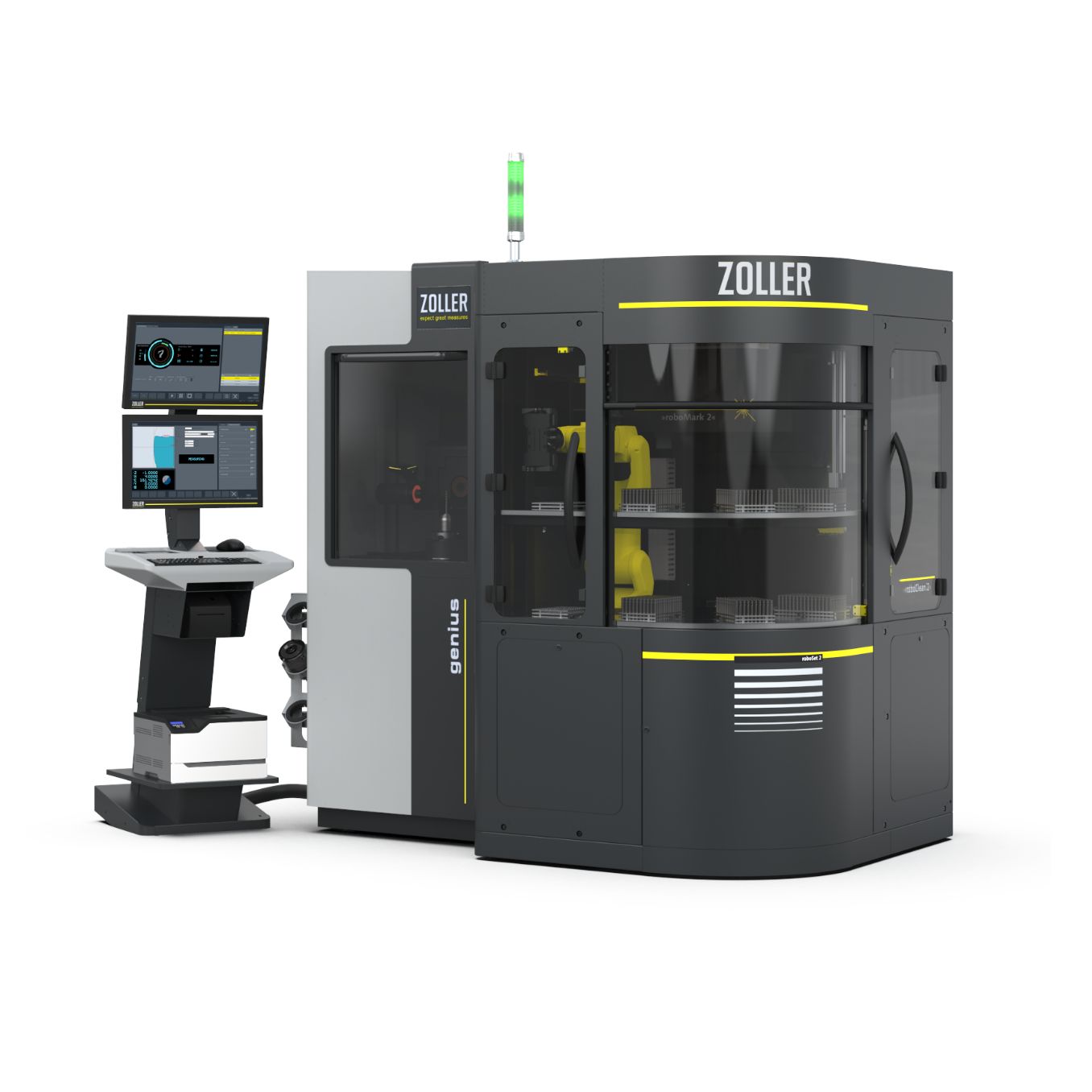

»genius«

This universal measuring machine provides comprehensive proof of quality for every cutting tool for more than 100 parameters. The »genius« performs non-contact inspections in 2D and 3D with high precision. From quick testing of individual criteria to fully automatic and operator-independent complete inspection, you have everything combined in one measuring machine.

The »titan« allows you to check the cutting edge preparation without contact - for the complete, informative documentation of your tools.

Tool inspection

»genius«

This universal measuring machine provides comprehensive proof of quality for every cutting tool for more than 100 parameters. The »genius« performs non-contact inspections in 2D and 3D with high precision. From quick testing of individual criteria to fully automatic and operator-independent complete inspection, you have everything combined in one measuring machine.

The »titan« allows you to check the cutting edge preparation without contact - for the complete, informative documentation of your tools.

Automation

»roboSet 2«

This Automation Solution for tool inspection ensures high throughput in a small space. Coupled to your ZOLLER universal measuring machine »titan«, »threadCheck« or »genius«, »roboSet 2« takes over the tool handling of large and small tool batches.

The potential for reducing personnel costs for tool inspection is close to 83 %.

Automation

»roboSet 2«

This Automation Solution for tool inspection ensures high throughput in a small space. Coupled to your ZOLLER universal measuring machine »titan«, »threadCheck« or »genius«, »roboSet 2« takes over the tool handling of large and small tool batches.

The potential for reducing personnel costs for tool inspection is close to 83 %.

- Tool management

Smart Cabinets

Intelligent storage and management solutions for grinding wheels, tools, components and accessories.

Perfectly coordinated with the ZOLLER TMS Tool Management Solutions software.

- Tool management

Smart Cabinets

Intelligent storage and management solutions for grinding wheels, tools, components and accessories.

Perfectly coordinated with the ZOLLER TMS Tool Management Solutions software.

- Balancing technology

»toolBalancer«

The »toolBalancer« ensures the concentricity of grinding wheels with an accuracy of < 0.4 gmm. With high-precision balanced grinding wheels, you fulfill an important and often underestimated requirement for first-class cutting edges and high geometry quality.

Balancing also protects the high-speed spindles of your CNC grinding machine. Even minor imbalances can put a massive strain on the spindle mechanics.

- Balancing technology

»toolBalancer«

The »toolBalancer« ensures the concentricity of grinding wheels with an accuracy of < 0.4 gmm. With high-precision balanced grinding wheels, you fulfill an important and often underestimated requirement for first-class cutting edges and high geometry quality.

Balancing also protects the high-speed spindles of your CNC grinding machine. Even minor imbalances can put a massive strain on the spindle mechanics.

- Presetting & measuring

»smile 420« and »venturion 450«

With the »smile 420« you can start with the professional presetting and measuring of standard tools. »venturion 450« is a premium level presetting and measuring machine.

What do these two ZOLLER Solutions have in common?: With easy-to-perform, µm-precise measurements, they shorten setup times and increase tool life.

The scalable annual savings potential per shift and CNC machine is around 15.000 euros.

- Presetting & measuring

»smile 420« and »venturion 450«

With the »smile 420« you can start with the professional presetting and measuring of standard tools. »venturion 450« is a premium level presetting and measuring machine.

What do these two ZOLLER Solutions have in common?: With easy-to-perform, µm-precise measurements, they shorten setup times and increase tool life.

The scalable annual savings potential per shift and CNC machine is around 15.000 euros.