Insert. Start. Measure. Finished!

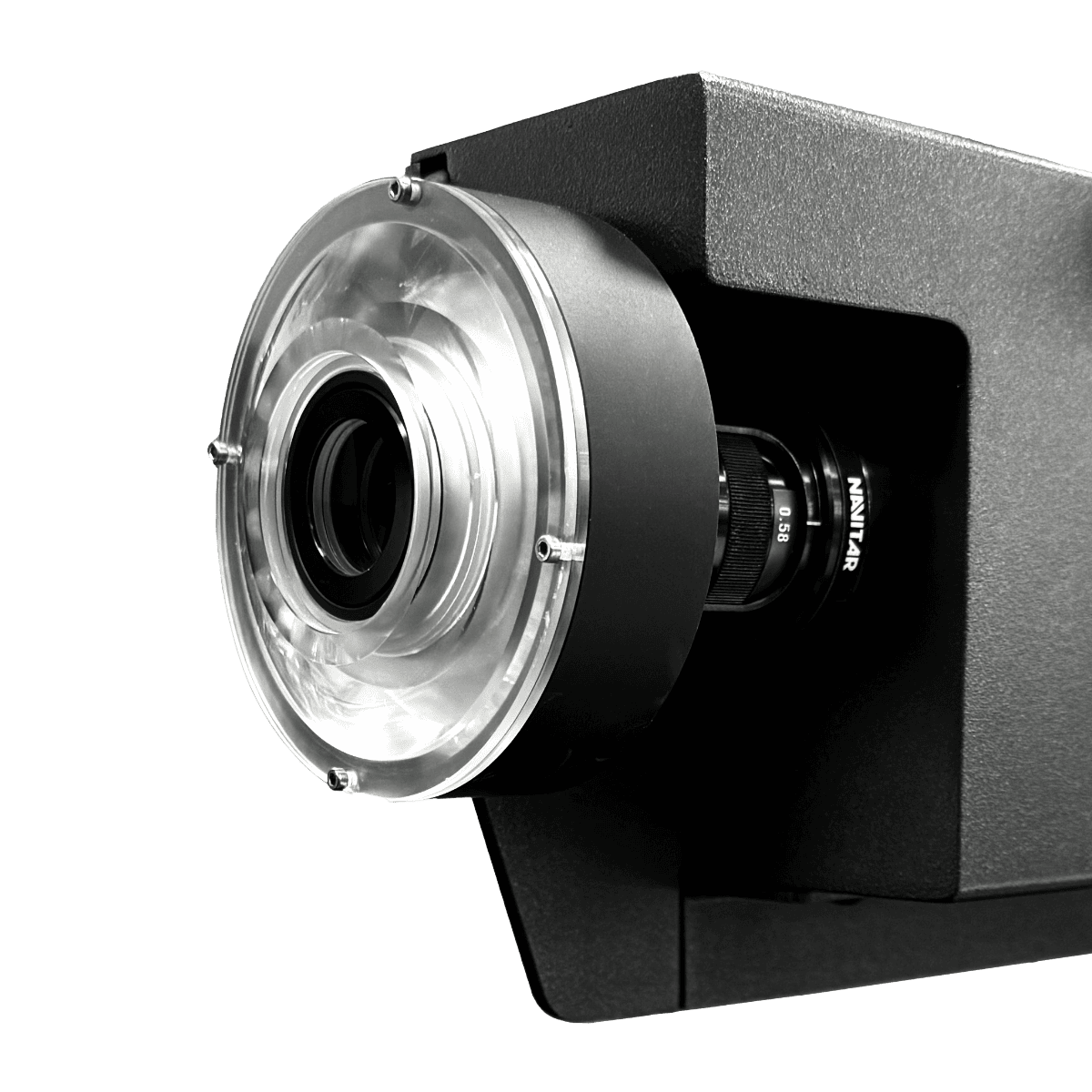

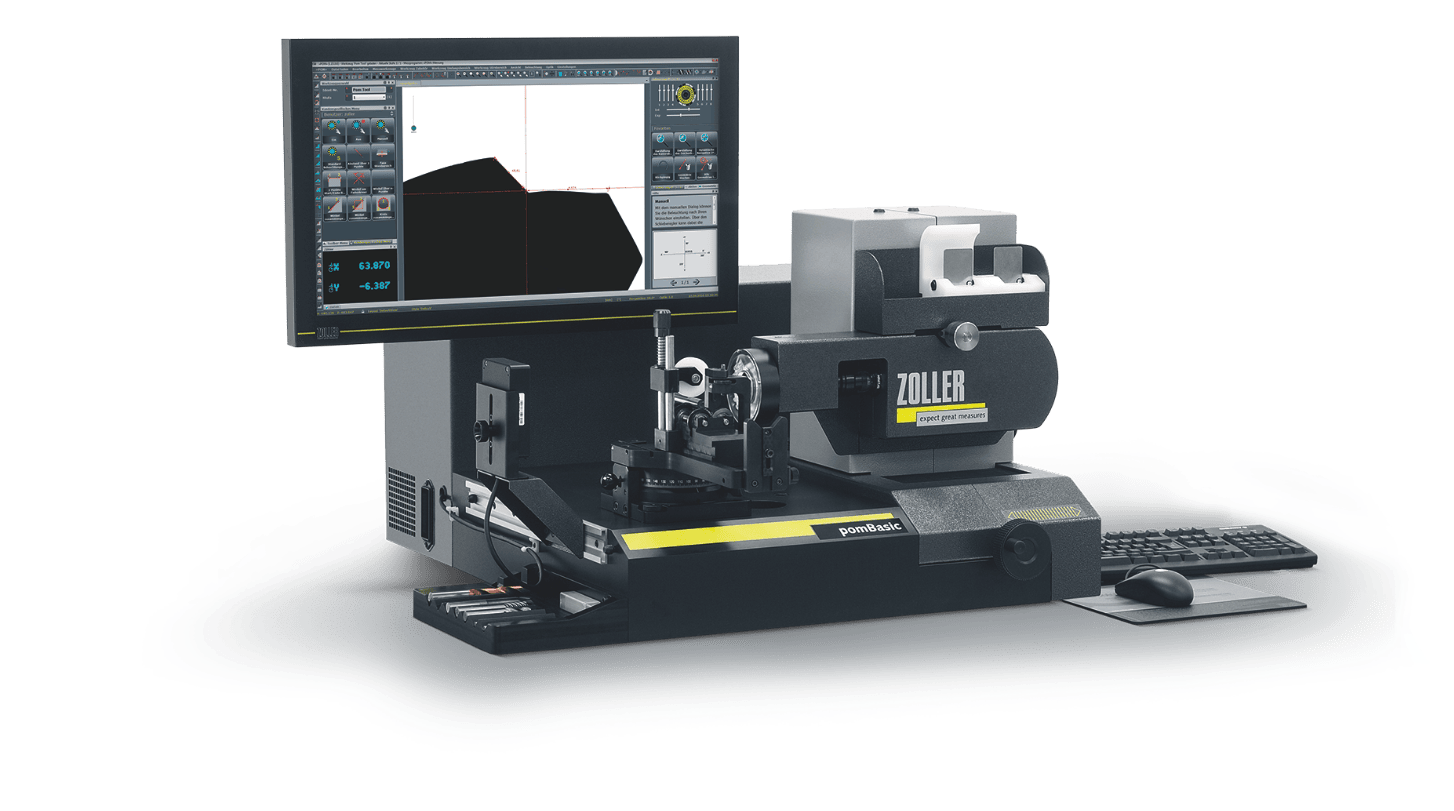

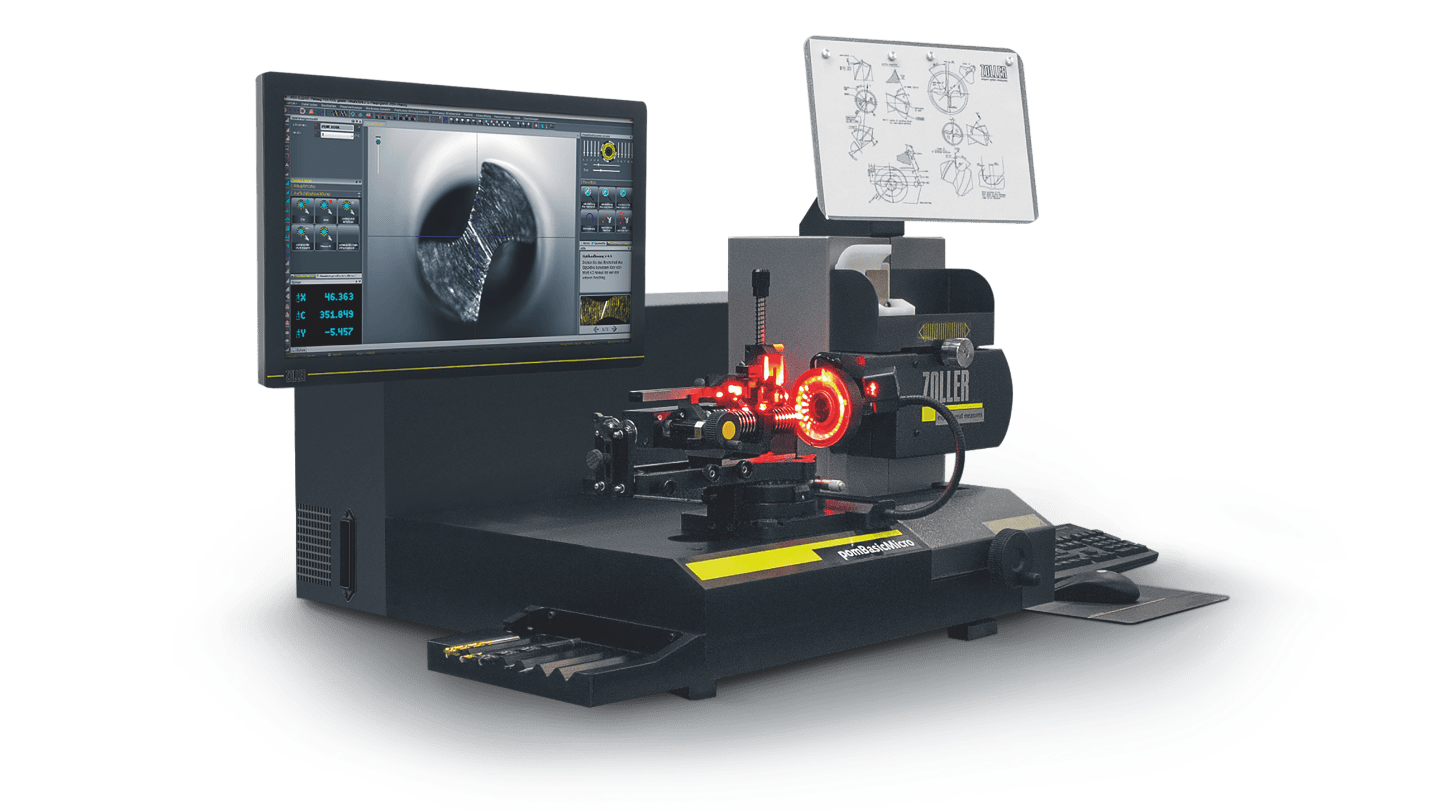

The »pomBasic« and »pomBasicMicro« manual, tabletop solutions create precise tool data from over 70 parameters in a matter of seconds, all with a minimal footprint.

Faster production, shorter distance

ZOLLER's process-oriented measurement boosts the profitability of tool manufacturers and grinding companies. Maximize your shop floor space and shorten the distance between manufacturing and your measuring process. Short distances, fast measuring, high efficiency.

The »pomBasic« and »pomBasicMicro« are your compact, easy-to-use inspection devices for precise inspection and documentation next to the CNC grinding machine.

Arrange 1:1 expert meeting

On track for quality

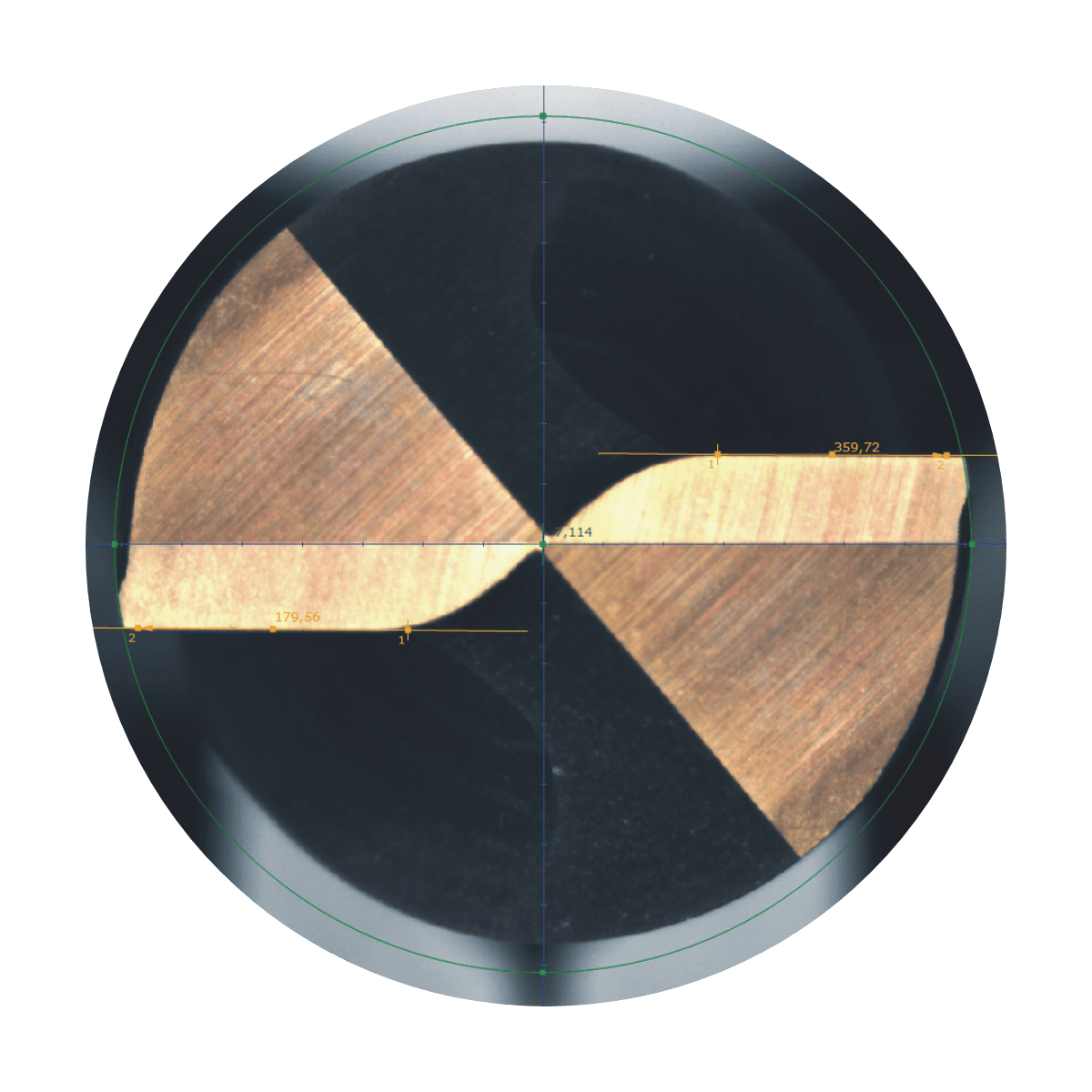

With both devices, you can measure geometries on the face and circumference. Thanks to precise data, you know whether you are on track for quality or need to make corrections when grinding.