Start with a solution

Enter a system

We will customize a solution that optimizes and fits

your manufacturing process.

Presetting and Measuring Machine »smile«

ZOLLER »smile« is a must for manufacturing companies carrying out machining work: easy to operate, exclusively constructed with high-quality brand name components, comes equipped with all standard measuring functions for professionally presetting and measuring cutting tools, and suitable for difficult shop floor use thanks to its well thought-out construction.

The variable control unit, the ergonomic single-hand operating handle »eQ« and the freely accessible tool clamp make work more comfortable. In addition to quick and precise measurements, the »smile« guarantees direct transmission of tool data to your machine. There’s plenty of reasons to greet the challenges that lie ahead with a smile.

Presetting and Measuring Machine »smile«

ZOLLER »smile« is a must for manufacturing companies carrying out machining work: easy to operate, exclusively constructed with high-quality brand name components, comes equipped with all standard measuring functions for professionally presetting and measuring cutting tools, and suitable for difficult shop floor use thanks to its well thought-out construction.

The variable control unit, the ergonomic single-hand operating handle »eQ« and the freely accessible tool clamp make work more comfortable. In addition to quick and precise measurements, the »smile« guarantees direct transmission of tool data to your machine. There’s plenty of reasons to greet the challenges that lie ahead with a smile.

Premium Presetting and Measuring Machine »venturion«

Our classic workhorse of the presetting line of Solutions is the »venturion«, a presetting and measuring machine that is characterized by unique ergonomics, maximum flexibility and precision. The module design of this presetting and measuring machine gives you the freedom to put together your individual presetting and measuring machine optimally matched to your production processes.

All the basic functions for measuring and presetting your tools are possible with the basic version – you profit from photorealistic input dialogs, automatic cutting edge detection, automatic zero point monitoring and much more. For example, modules can be added for tool inspection, for center height measuring, for measuring reamers or for heat shrinking tools. »venturion« offers every possibility for individual adjustment.

Premium Presetting and Measuring Machine »venturion«

Our classic workhorse of the presetting line of Solutions is the »venturion«, a presetting and measuring machine that is characterized by unique ergonomics, maximum flexibility and precision. The module design of this presetting and measuring machine gives you the freedom to put together your individual presetting and measuring machine optimally matched to your production processes.

All the basic functions for measuring and presetting your tools are possible with the basic version – you profit from photorealistic input dialogs, automatic cutting edge detection, automatic zero point monitoring and much more. For example, modules can be added for tool inspection, for center height measuring, for measuring reamers or for heat shrinking tools. »venturion« offers every possibility for individual adjustment.

Toolmanagement Smart Cabinets

Our Smart Cabinets storage solutions stand for significant time and costs savings. Thanks to transparent warehouse stock, the right quantity of tools is always available. Eliminate costly time spent searching for tools. Tool information is at your fingertips so you know exactly where your tools are, always. Discover our storage solutions »toolOrganizer«, »keeper«, »toolCart«, »toolStation«, »autoLock«, »twister«, »zTower« – and the brand-new »toolCart 750«. Profit of the fast location and availability of your items and save time and costs.

Toolmanagement Smart Cabinets

Our Smart Cabinets storage solutions stand for significant time and costs savings. Thanks to transparent warehouse stock, the right quantity of tools is always available. Eliminate costly time spent searching for tools. Tool information is at your fingertips so you know exactly where your tools are, always. Discover our storage solutions »toolOrganizer«, »keeper«, »toolCart«, »toolStation«, »autoLock«, »twister«, »zTower« – and the brand-new »toolCart 750«. Profit of the fast location and availability of your items and save time and costs.

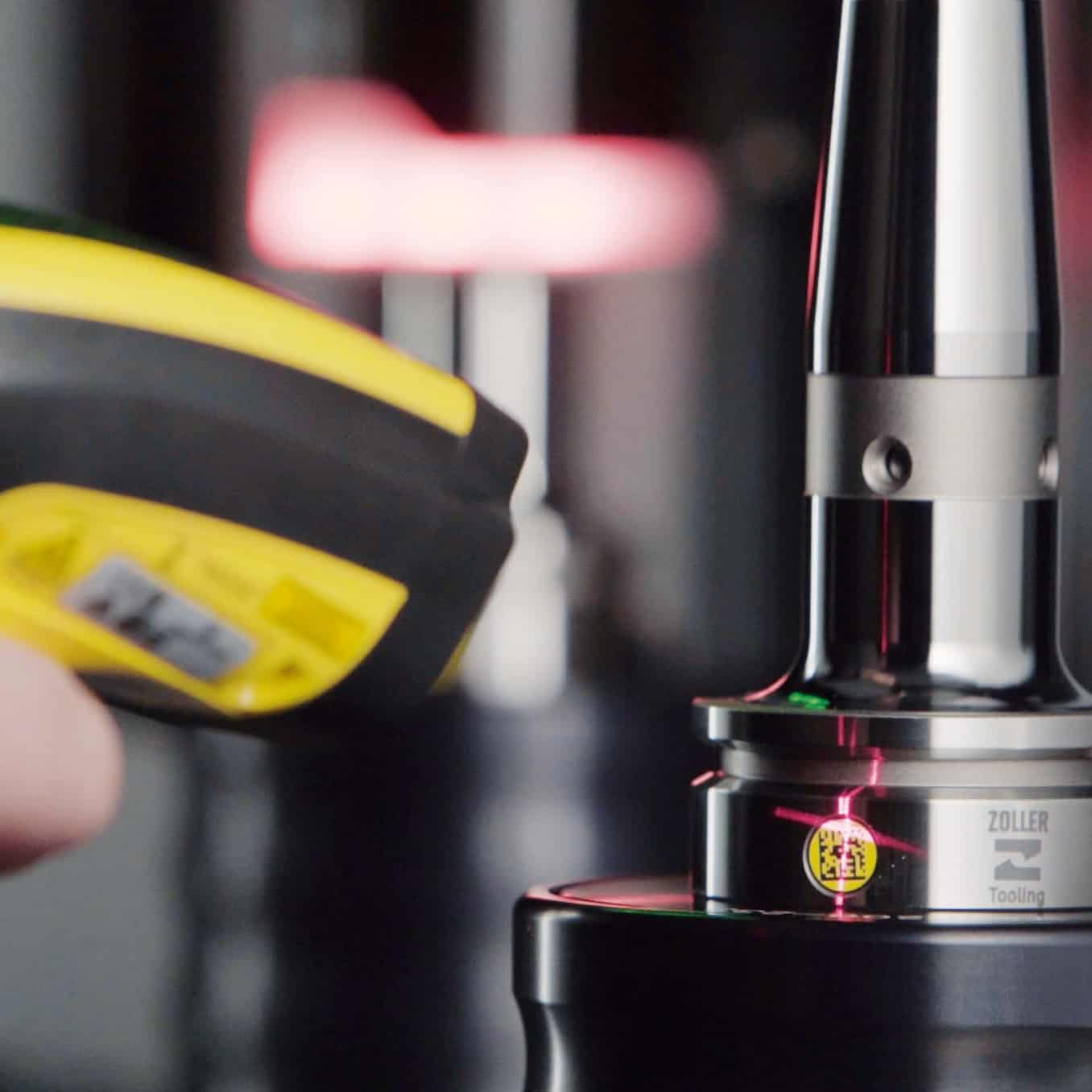

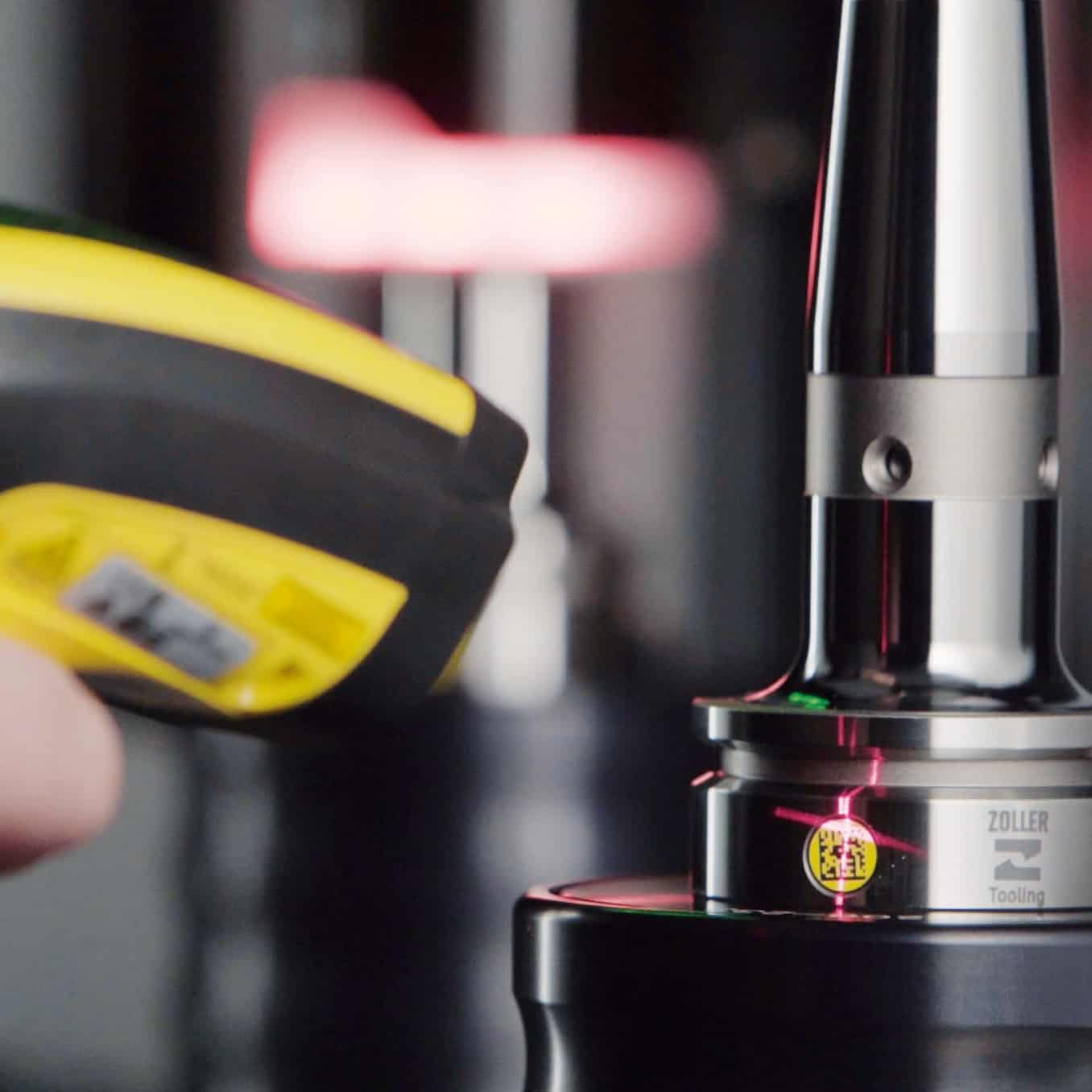

Tool Identification ZOLLER »zidCode«

Identify tools within your manufacturig process and transfer tool data securely to the machine. With »zidCode« you avoid crashes on CNC machines. With ZOLLERs »zidCode« and »zidCode 4.0«, you can transmit the measurement and setting data as well as the tool ID digitally and error-free to almost any common CNC machine and thus avoid the machine crash.

»zidCode« quickly gets your production ready to use digital tool data conveniently in your processes. After just a short time, your data will flow to the CNC machine without errors and in a control-ready manner.

Tool Identification ZOLLER »zidCode«

Identify tools within your manufacturig process and transfer tool data securely to the machine. With »zidCode« you avoid crashes on CNC machines. With ZOLLERs »zidCode« and »zidCode 4.0«, you can transmit the measurement and setting data as well as the tool ID digitally and error-free to almost any common CNC machine and thus avoid the machine crash.

»zidCode« quickly gets your production ready to use digital tool data conveniently in your processes. After just a short time, your data will flow to the CNC machine without errors and in a control-ready manner.

Automation Solutions

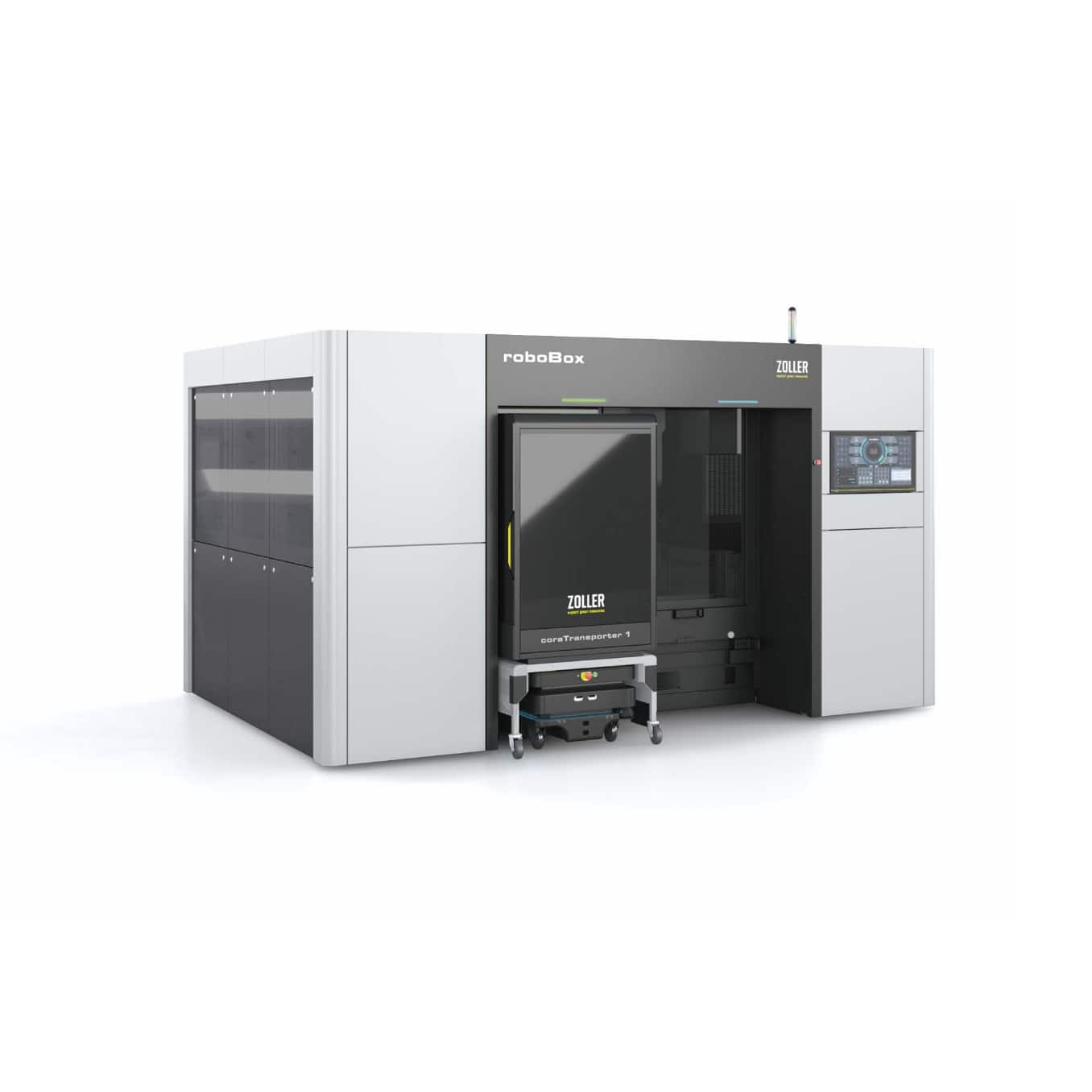

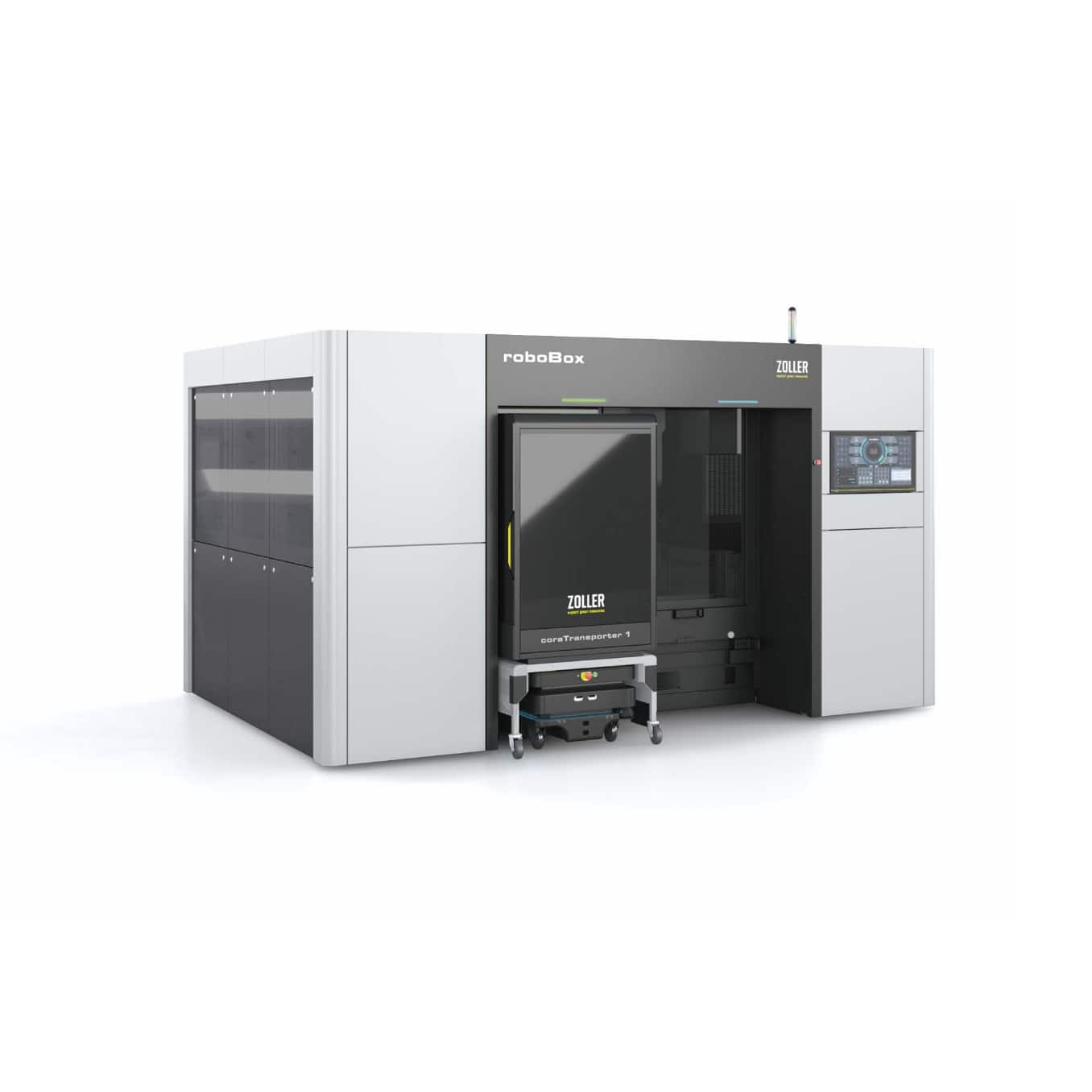

»roboBox«

ZOLLER is super excited to present to you the »roboBox«, the central systems component for your digitized, automated Industry 4.0 production process. Visitors to the ZOLLER booth will experience first hand this revolutionary automated modular assembly and measurement system for cutting tools.

Experience this system solution live that automatically assembles shrink fit holders and cutting tools together! You will be amazed at the ease of which one can fully integrate automatic tool logistics and delivery into each production process!

Automation Solutions

»roboBox«

ZOLLER is super excited to present to you the »roboBox«, the central systems component for your digitized, automated Industry 4.0 production process. Visitors to the ZOLLER booth will experience first hand this revolutionary automated modular assembly and measurement system for cutting tools.

Experience this system solution live that automatically assembles shrink fit holders and cutting tools together! You will be amazed at the ease of which one can fully integrate automatic tool logistics and delivery into each production process!

Universal Measuring Machine »smartCheck«

Whether as a manual or 3-axis-CNC version: »smartCheck« is the powerful universal measuring and inspection machine for all cutting tools! As a result you can check your tools efficiently before and after grinding in order to fulfill DIN EN ISO 9000 guidelines.

In addition, with the swiveling incident light image processing software, you can inspect, measure and document axial and radial geometries of tools– very easily in a single click without expert-level knowledge. You profit directly from at least a 25% productivity increase with your CNC grinding machines simply by measuring your tools before regrinding.

Universal Measuring Machine »smartCheck«

Whether as a manual or 3-axis-CNC version: »smartCheck« is the powerful universal measuring and inspection machine for all cutting tools! As a result you can check your tools efficiently before and after grinding in order to fulfill DIN EN ISO 9000 guidelines.

In addition, with the swiveling incident light image processing software, you can inspect, measure and document axial and radial geometries of tools– very easily in a single click without expert-level knowledge. You profit directly from at least a 25% productivity increase with your CNC grinding machines simply by measuring your tools before regrinding.

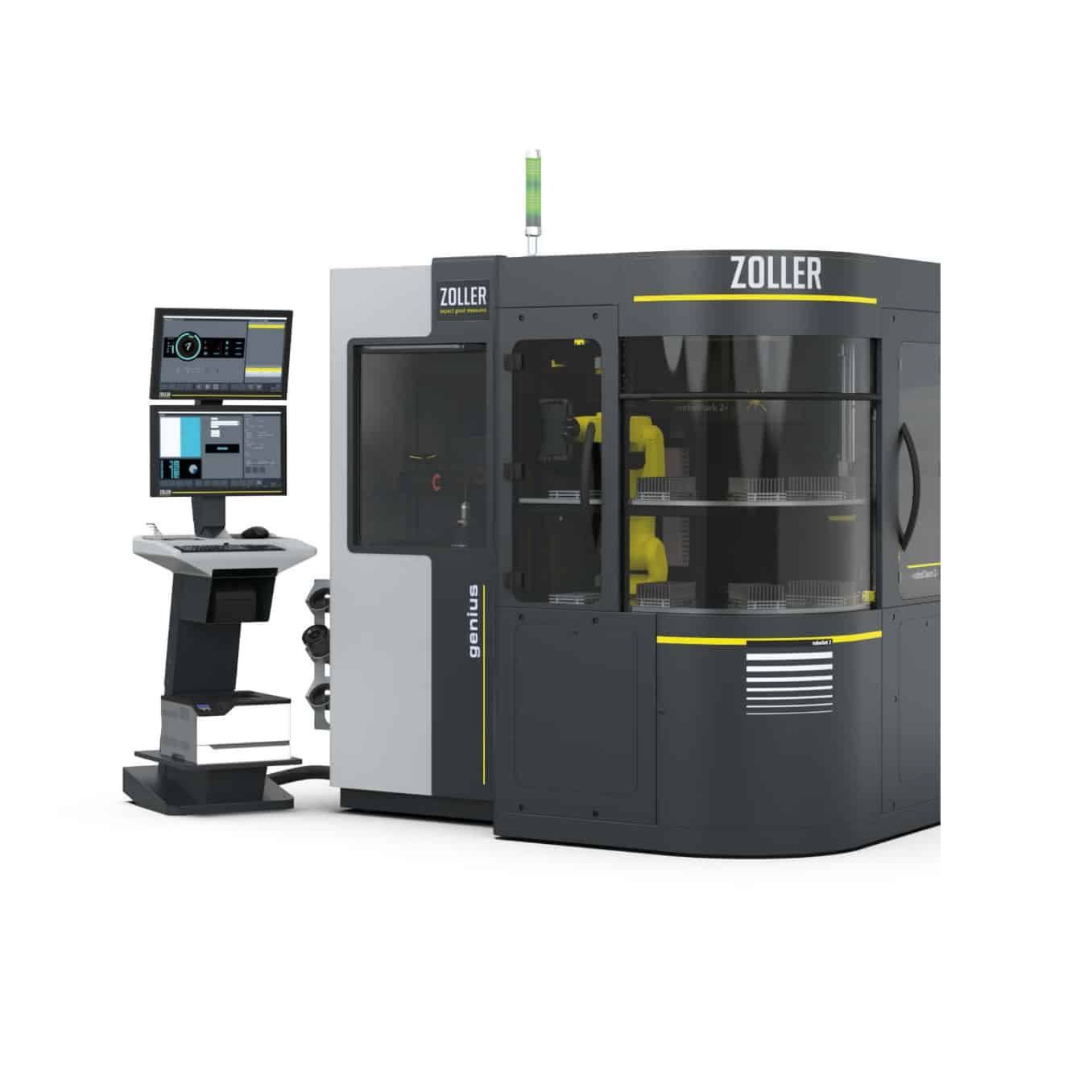

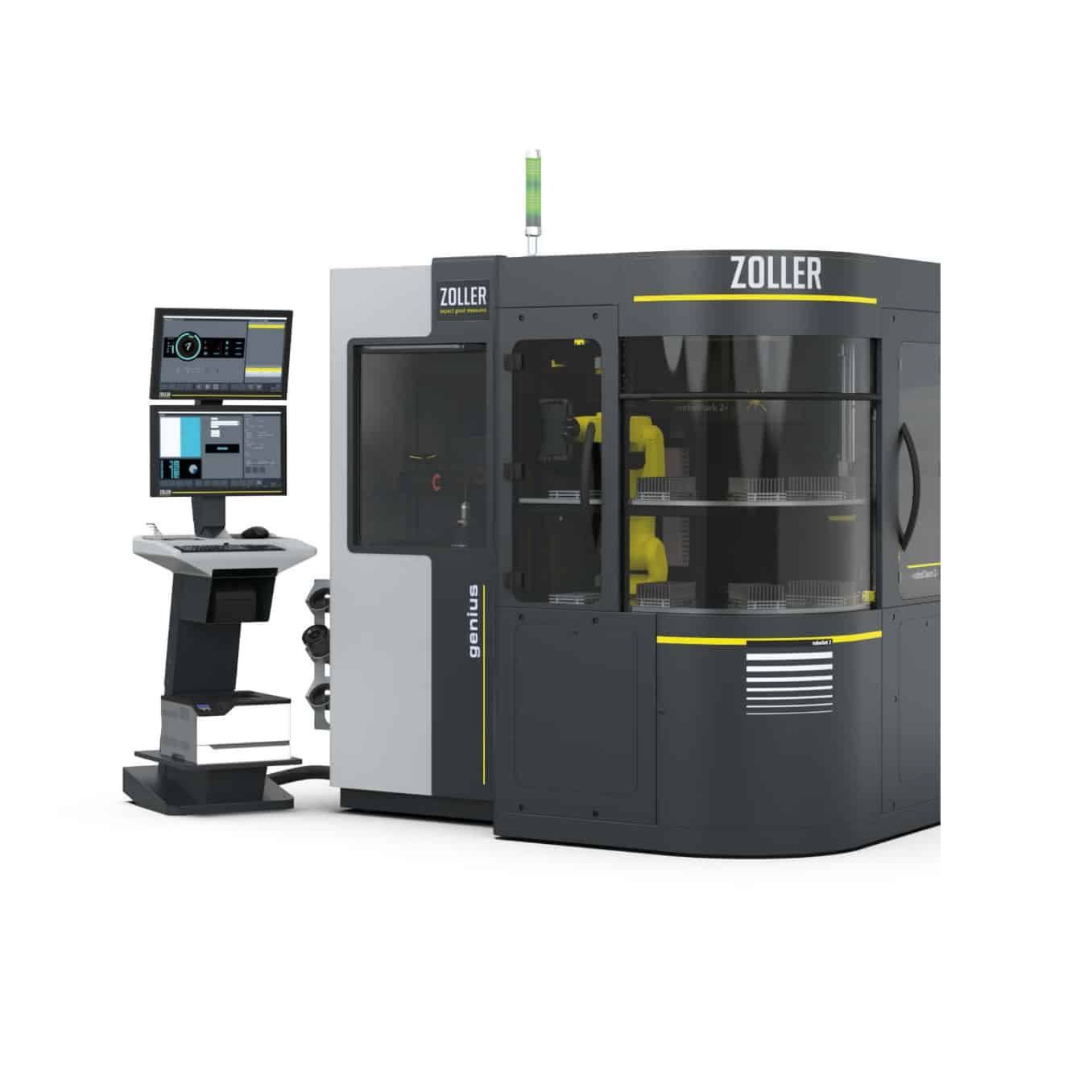

Universal Measuring Machine »genius«

The best selling »genius« is a universal measuring machine and is the perfect solution for the measurement and inspection of your cutting tools quickly, simply and precisely. It can easily handle everything from the quick testing of individual criteria to the fully automatic and operator-independent measurement of more than 100 parameters on standard and micro tools.

Applications range from incoming inspection, in-house regrinding, research, benchmarking, wear analysis, tool setup, in-process control, final inspection to cutting tool certification and reverse engineering. The new »pilot 4.0« image processing software equips users to run any measurement and inspection program for any requirement including typical tool measurement of helix angles, radial reliefs, lands, gash angles, head lengths, center offsets, chamfer heights and end face facets to list but a few.

Universal Measuring Machine »genius«

The best selling »genius« is a universal measuring machine and is the perfect solution for the measurement and inspection of your cutting tools quickly, simply and precisely. It can easily handle everything from the quick testing of individual criteria to the fully automatic and operator-independent measurement of more than 100 parameters on standard and micro tools.

Applications range from incoming inspection, in-house regrinding, research, benchmarking, wear analysis, tool setup, in-process control, final inspection to cutting tool certification and reverse engineering. The new »pilot 4.0« image processing software equips users to run any measurement and inspection program for any requirement including typical tool measurement of helix angles, radial reliefs, lands, gash angles, head lengths, center offsets, chamfer heights and end face facets to list but a few.

Automation Solutions

»roboSet 2«

In hall 4 at booth E70 at the EMO 2023, see the industry gamechanger for 24/7 light out cutting tool inspection solution for efficient quality control! Your production throughput can be maximised with the fully automated loading station that allows a ZOLLER »genius« machine to operate with total accuracy around the clock. Predefined program selection within »pilot 3.4« software caters for the recording of more than 50 measurement parameters with micron precision without any operator intervention. Once the checking procedure is complete, faulty tools are automatically separated from the correct ones.

It’s the perfect solution for efficient quality control at high tool volumes.

Automation Solutions

»roboSet 2«

In hall 4 at booth E70 at the EMO 2023, see the industry gamechanger for 24/7 light out cutting tool inspection solution for efficient quality control! Your production throughput can be maximised with the fully automated loading station that allows a ZOLLER »genius« machine to operate with total accuracy around the clock. Predefined program selection within »pilot 3.4« software caters for the recording of more than 50 measurement parameters with micron precision without any operator intervention. Once the checking procedure is complete, faulty tools are automatically separated from the correct ones.

It’s the perfect solution for efficient quality control at high tool volumes.

Inspection Machine »mμFocus«

You want to produce the perfect cutting edge – one that ensures a long tool life, minimal wear, optimal chip formation, and precision workpiece processing, thereby significantly lowering costs for production?

Achieve your goals with high-precision tool geometry and optimal surface textures customized to your specific application. If you want to ensure exact, standardized quality in your tool development, then the ZOLLER »mμFocus« inspection machine is the right choice for your needs. »mµFocus« uses non-contact measurement procedures to determine the surface roughness and cutting edge preparation of your tool, down to the µm. Use the ZOLLER »mμFocus« to create fully optimized tools.

Inspection Machine »mμFocus«

You want to produce the perfect cutting edge – one that ensures a long tool life, minimal wear, optimal chip formation, and precision workpiece processing, thereby significantly lowering costs for production?

Achieve your goals with high-precision tool geometry and optimal surface textures customized to your specific application. If you want to ensure exact, standardized quality in your tool development, then the ZOLLER »mμFocus« inspection machine is the right choice for your needs. »mµFocus« uses non-contact measurement procedures to determine the surface roughness and cutting edge preparation of your tool, down to the µm. Use the ZOLLER »mμFocus« to create fully optimized tools.

»powerShrink 400/600«

The New ZOLLER Heat Shrink System

Clamping and unclamping tools in record time and saving energy and conserving tool holders: You get all these benefits with the new inductive »powerShrink« heat shrink system.

Our product development team factored in maximum energy efficiency as well as a fast and reliable shrinking process with maximal safety – which is very important for ZOLLER customers, allowing more profitability and efficiency in their shops.

»powerShrink 400/600«

The New ZOLLER Heat Shrink System

Clamping and unclamping tools in record time and saving energy and conserving tool holders: You get all these benefits with the new inductive »powerShrink« heat shrink system.

Our product development team factored in maximum energy efficiency as well as a fast and reliable shrinking process with maximal safety – which is very important for ZOLLER customers, allowing more profitability and efficiency in their shops.

Tooling Solutions with »idChip«

Tool holders with ZOLLER »idChip« - the perfect interface for digital manufacturing. The integrated chip and DataMatrix code allows you to clearly identify your tool holder at all times, with a comprehensive overview of information: the number of heating processes, uses on the machine, and much more.

The ZOLLER »idChip« is made of exeptionally robust material. The 3-groove-technology in the chip bore of the tool holder guarantees a form fit with the adhesive, for safe and fixed connection.

We go one step further and present the ZOLLER Tooling Solutions online: Our web shop in the customer portal MYZOLLER ensures a simple, clear and quick overview of the selection of your requested products, in addition to providing the digital twin at the push of a button.

Tooling Solutions with »idChip«

Tool holders with ZOLLER »idChip« - the perfect interface for digital manufacturing. The integrated chip and DataMatrix code allows you to clearly identify your tool holder at all times, with a comprehensive overview of information: the number of heating processes, uses on the machine, and much more.

The ZOLLER »idChip« is made of exeptionally robust material. The 3-groove-technology in the chip bore of the tool holder guarantees a form fit with the adhesive, for safe and fixed connection.

We go one step further and present the ZOLLER Tooling Solutions online: Our web shop in the customer portal MYZOLLER ensures a simple, clear and quick overview of the selection of your requested products, in addition to providing the digital twin at the push of a button.

»toolBalancer 550/750«

The New ZOLLER Balancing System

The gamechanging »toolBalancer« enables you to increase your process reliability and the quality of your components, reduce machine maintenance costs and prevent machine failures. How does it work? It’s simple: Highly-precisely balanced tools allow you to achieve longer tool life, higher spindle running time and better surface quality of your components. Experience the new balancing system from ZOLLER with the most modern technology and innovative ergonomic design.

»toolBalancer 550/750«

The New ZOLLER Balancing System

The gamechanging »toolBalancer« enables you to increase your process reliability and the quality of your components, reduce machine maintenance costs and prevent machine failures. How does it work? It’s simple: Highly-precisely balanced tools allow you to achieve longer tool life, higher spindle running time and better surface quality of your components. Experience the new balancing system from ZOLLER with the most modern technology and innovative ergonomic design.