We Stand for Smart Progress

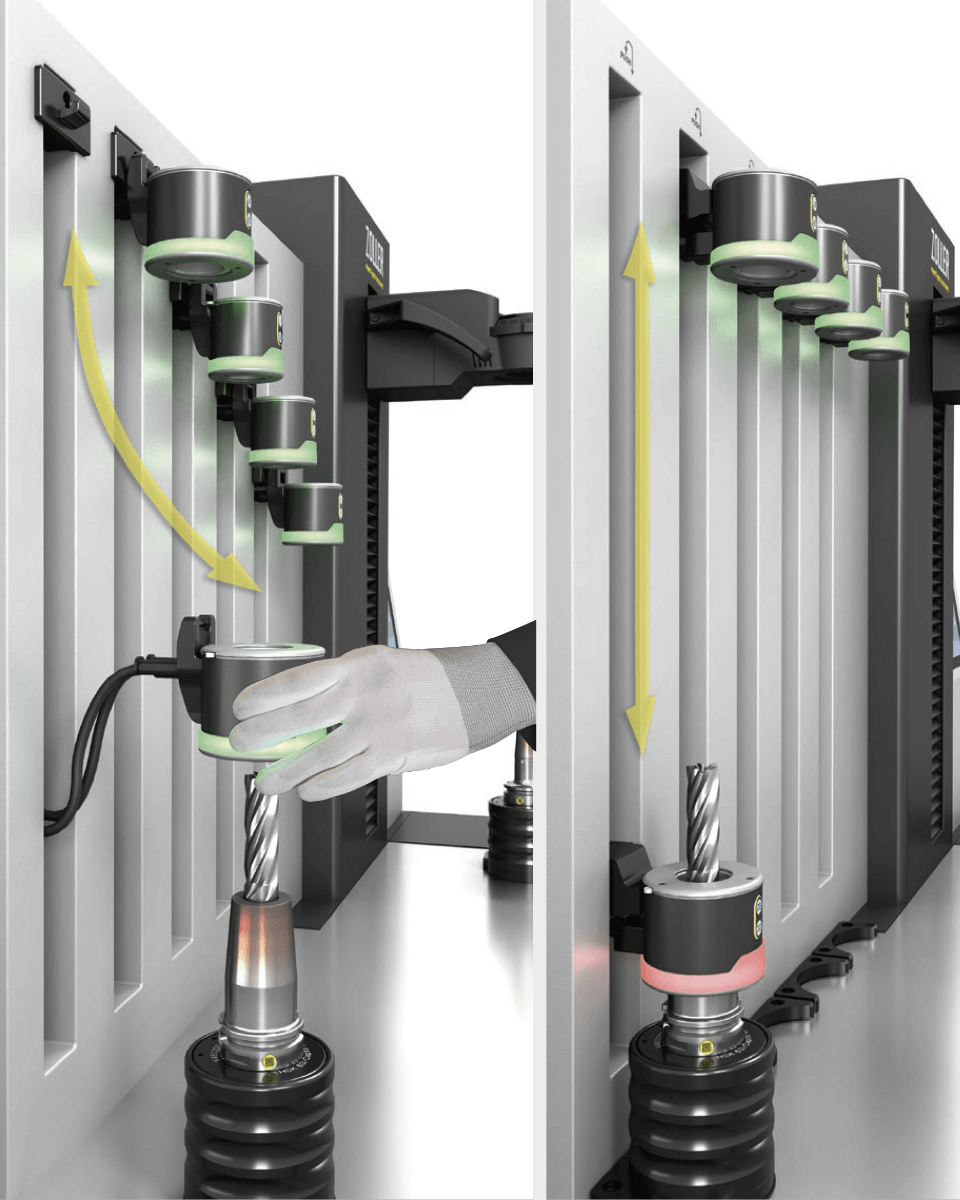

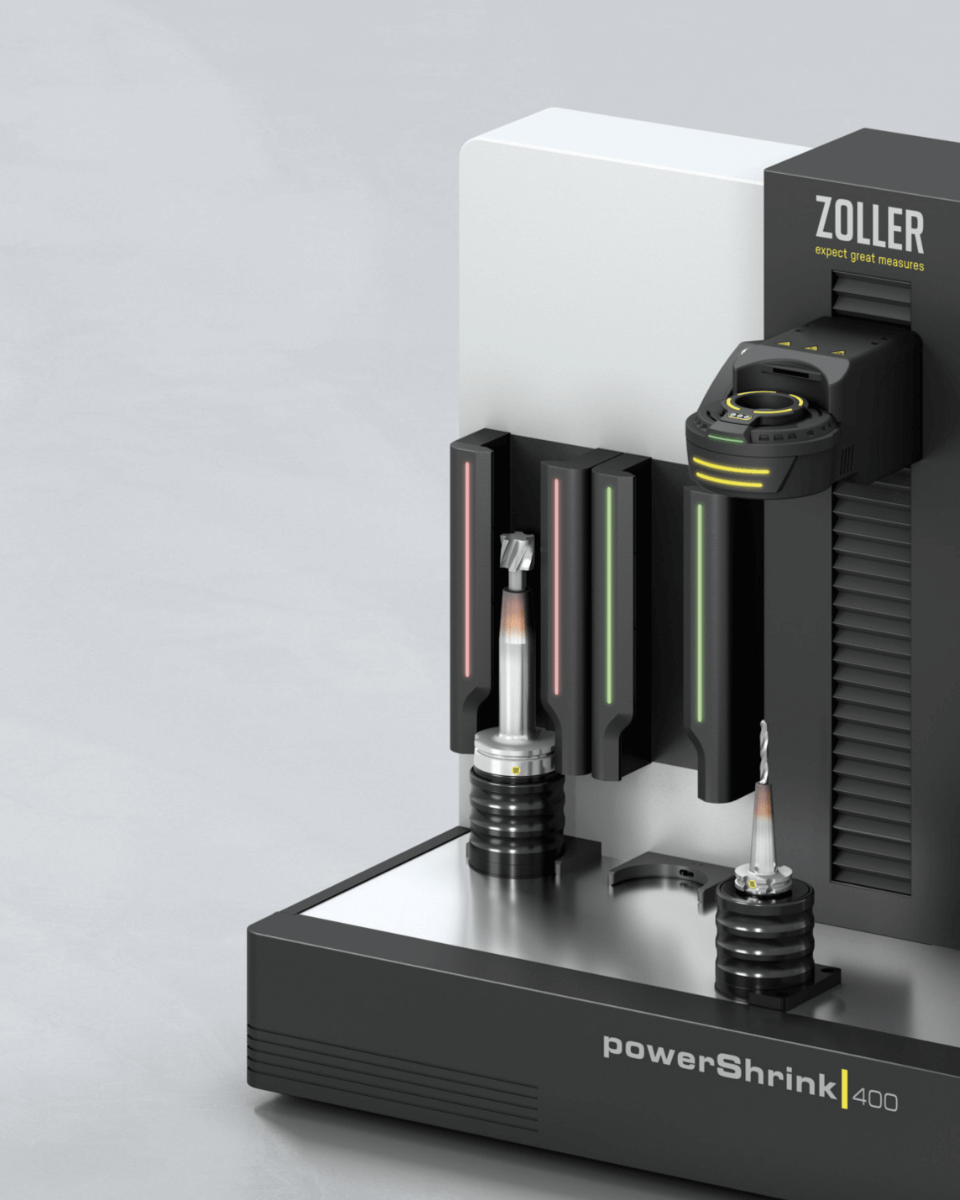

Clamping and unclamping tools in record time and saving energy and conserving tool holders: You get all these benefits with the inductive »powerShrink« heat shrink system. With the »powerShrink« machine series, you increase production efficiency.

»actbyLight« guides you safely through the clamping process and includes the »shrinkbyLight« coil function, the LED-control on the induction coil, and the LED operating guide »coolbyLight« on the cooling system.

We Stand for Smart Progress

Clamping and unclamping tools in record time and saving energy and conserving tool holders: You get all these benefits with the inductive »powerShrink« heat shrink system. With the »powerShrink« machine series, you increase production efficiency.

»actbyLight« guides you safely through the clamping process and includes the »shrinkbyLight« coil function, the LED-control on the induction coil, and the LED operating guide »coolbyLight« on the cooling system.

Shrink-clamping technology

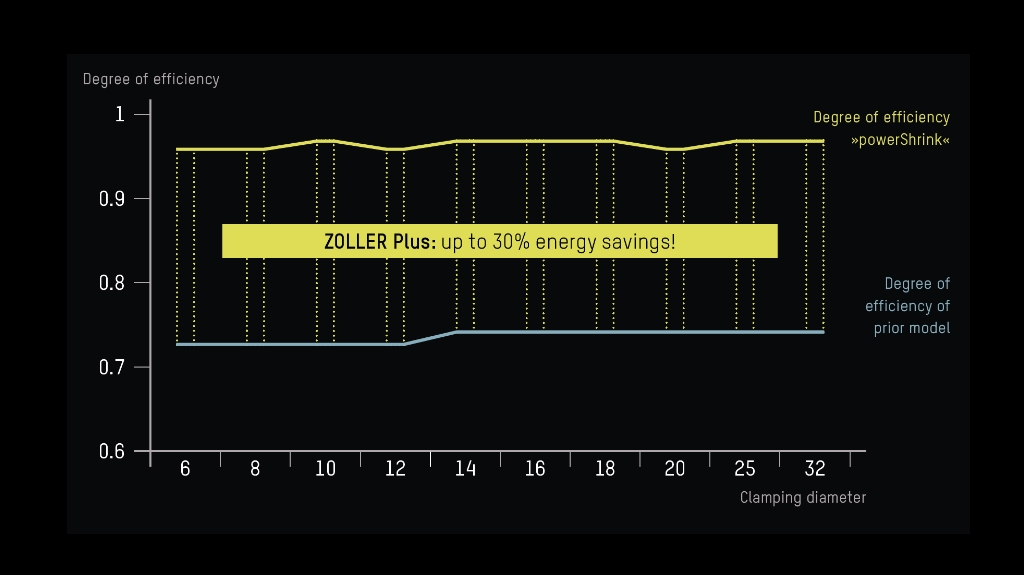

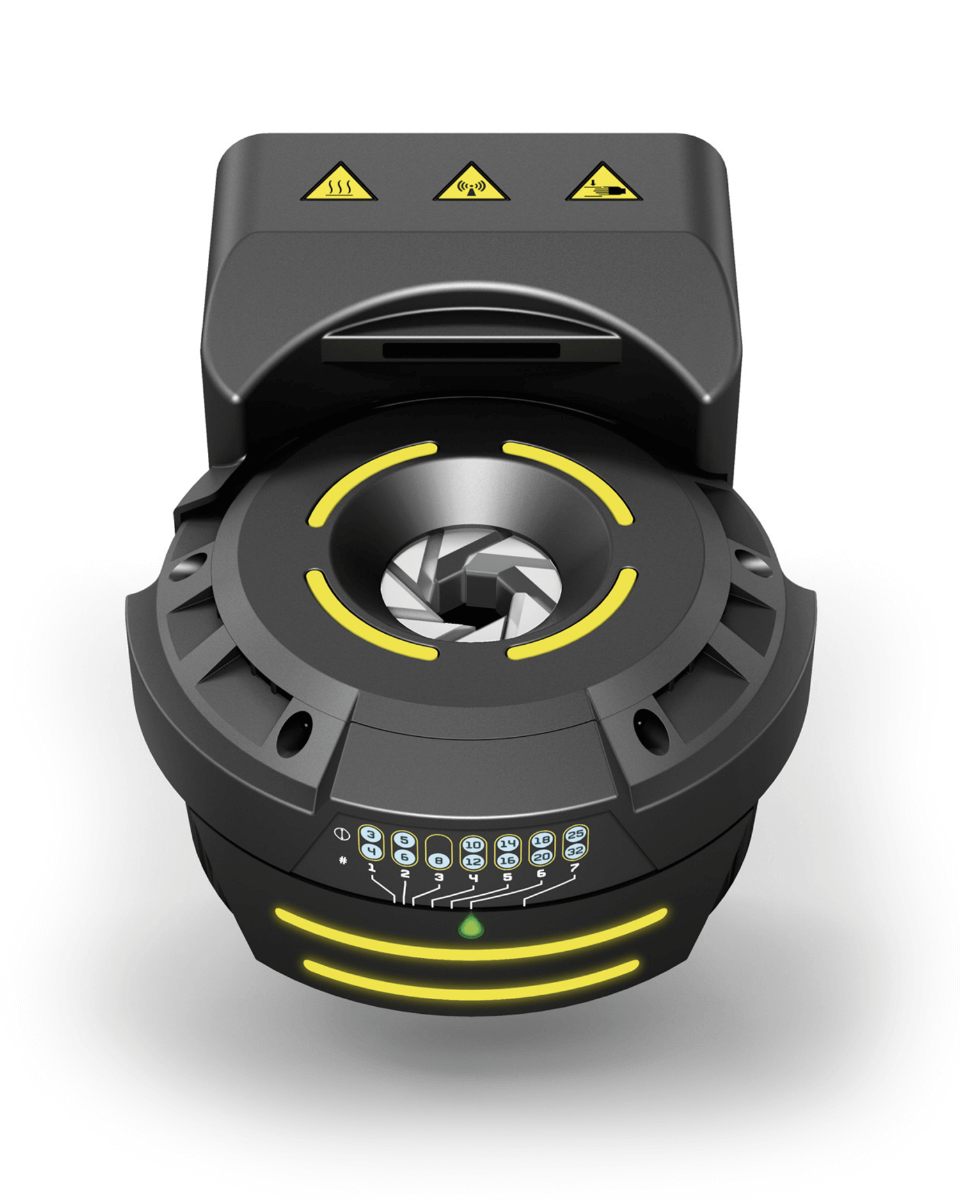

Smart Design for Maximal Efficiency

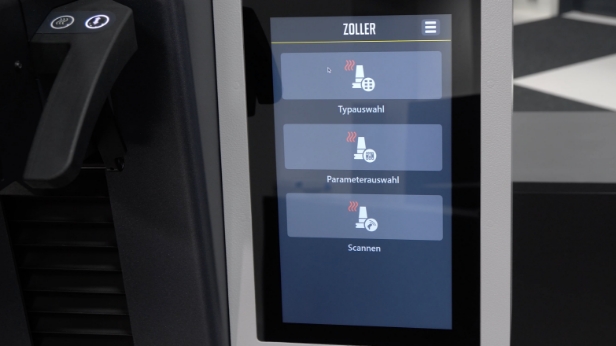

The ZOLLER induction coil, an intelligent, well-conceived »powerShrink« highlight. Two parallel-connected windings within the coil can be activated can be activated and controlled separately, depending on the clamp diameter and length. This enables optimum energy input into the clamping area, accelerating the heating and cooling process, in addition to protecting your tool-holding fixture.

Shrink-clamping technology

Smart Design for Maximal Efficiency

The ZOLLER induction coil, an intelligent, well-conceived »powerShrink« highlight. Two parallel-connected windings within the coil can be activated can be activated and controlled separately, depending on the clamp diameter and length. This enables optimum energy input into the clamping area, accelerating the heating and cooling process, in addition to protecting your tool-holding fixture.

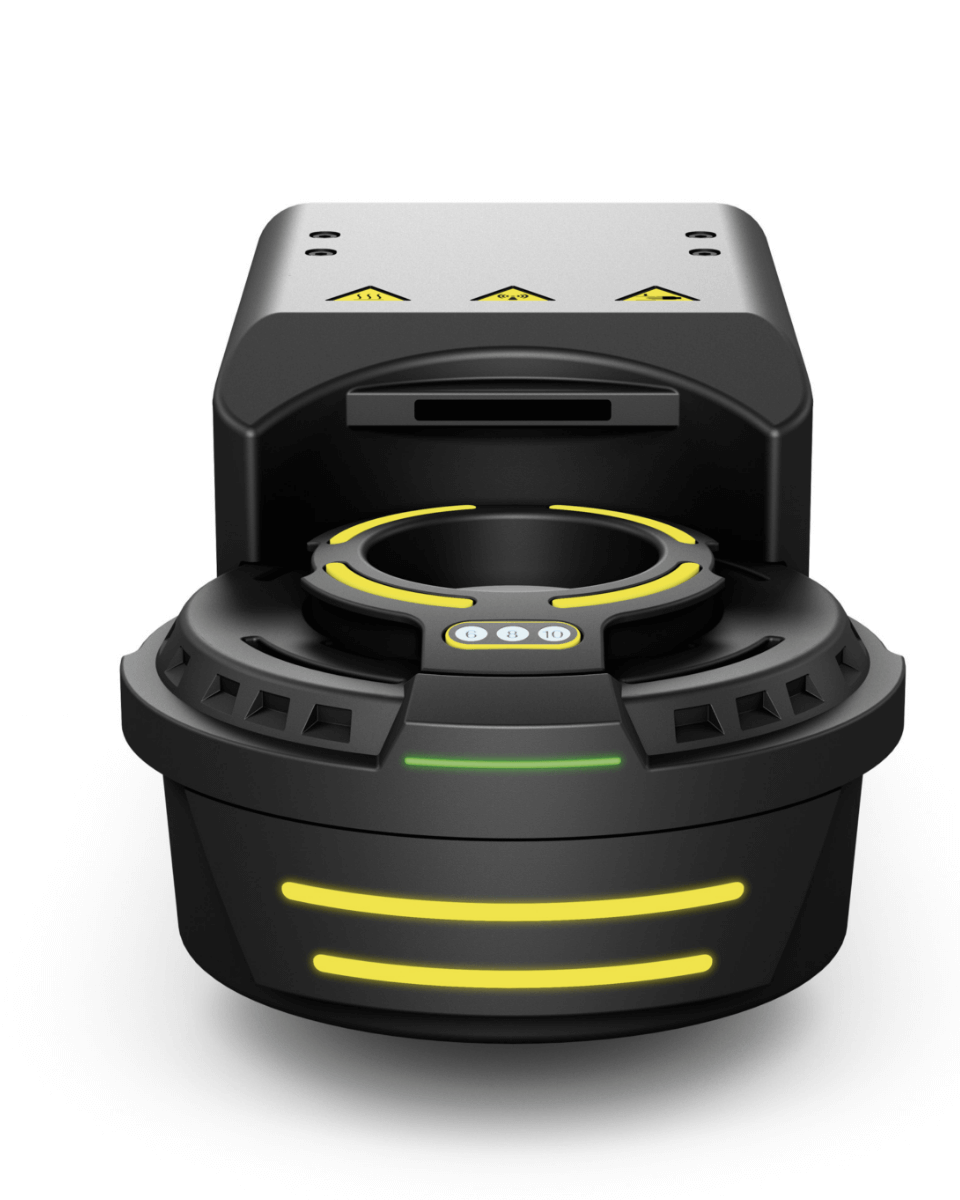

»coolbyLight«

Cool Highlights for Efficient Cooling

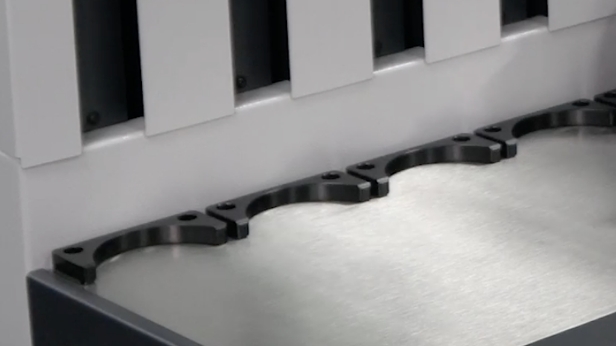

With »powerShrink« by ZOLLER, you cool with maximum efficiency. The five cooling bells for standard shrink fit tool holders, from D6 mm to D32 mm, ensure fast, consistent cooling thanks to their intelligent design and integrated contact cooling. Your shrink fit tool holders are protected and high true-running accuracy is maintained.

»coolbyLight«

Cool Highlights for Efficient Cooling

With »powerShrink« by ZOLLER, you cool with maximum efficiency. The five cooling bells for standard shrink fit tool holders, from D6 mm to D32 mm, ensure fast, consistent cooling thanks to their intelligent design and integrated contact cooling. Your shrink fit tool holders are protected and high true-running accuracy is maintained.

We Stand for Reliable Quality

100% made in Germany – that is our primary mission, and we work hard to ensure we achieve our goals. Thanks to an expansion of our production site in Pleidelsheim, Germany, our production is now even more efficient and economical.

The ZOLLER assembly – a team of specialized, competent employees from assembly and quality assurance ensure, day by day, that your »powerShrink« reaches your production facility in perfect condition. Your »powerShrink« does not leave the assembly line until all our employees are 100% satisfied, and the machine has the ZOLLER seal of quality. We are proud of this.

We Stand for Reliable Quality

100% made in Germany – that is our primary mission, and we work hard to ensure we achieve our goals. Thanks to an expansion of our production site in Pleidelsheim, Germany, our production is now even more efficient and economical.

The ZOLLER assembly – a team of specialized, competent employees from assembly and quality assurance ensure, day by day, that your »powerShrink« reaches your production facility in perfect condition. Your »powerShrink« does not leave the assembly line until all our employees are 100% satisfied, and the machine has the ZOLLER seal of quality. We are proud of this.