We Stand for Smart Progress

With optimally- and highly-precisely balanced tools, you achieve longer tool life, a longer spindle running time and a better surface quality of your components. With »toolBalancer«, not only do you get your tools but also your entire production into the perfect balance of sustainability, efficiency and progress.

We Stand for Smart Progress

With optimally- and highly-precisely balanced tools, you achieve longer tool life, a longer spindle running time and a better surface quality of your components. With »toolBalancer«, not only do you get your tools but also your entire production into the perfect balance of sustainability, efficiency and progress.

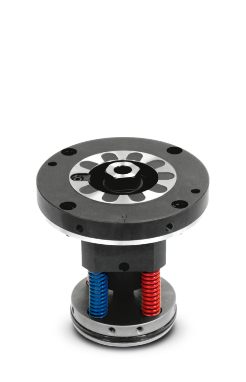

Our Adapters, Reliable and Precise

The selection of high-precision ZOLLER balancing adapters with a unique design facilitate power-activated and safe clamping of SK, HSK, polygonal shank coupling adapters and more, with even better repeat precision than ever before.

SK-Adapter –

SK 30/40/50

SK-Adapter –

SK 30/40/50

- Pneumatic clamping principle with power spring package

- High reproducibility and repeatability

- Centering pins with ejector to easily change the tool holder

- Maximum repeatability thanks to a chuck holder without radial or axial clearance

- 5-point system for backlash-free pick-up of the steep taper

- Certified safety at adapter change

- SK holders can be balanced without clamping bolts

HSK-Adapter –

HSK 32/40/50/63/80/100

(A/C/E-B/D/F)

HSK-Adapter –

HSK 32/40/50/63/80/100

(A/C/E-B/D/F)

- Pneumatic clamping principle with power spring package

- High reproducibility and repeatability

- Centering pins with ejector to easily change the tool holder

- Maximum repeatability thanks to a chuck holder without radial or axial clearance

- Certified safety at adapter change

Polygonal Shank

Coupling Adapt –

C 32/40/50/63/80

Polygonal Shank

Coupling Adapt –

C 32/40/50/63/80

- Pneumatic clamping principle with power spring package

- High reproducibility and repeatability

- Centering pins with ejector to easily change the tool holder

- Maximum repeatability thanks to a chuck holder without radial or axial clearance

- Certified safety at adapter change

Further adapters available on request.

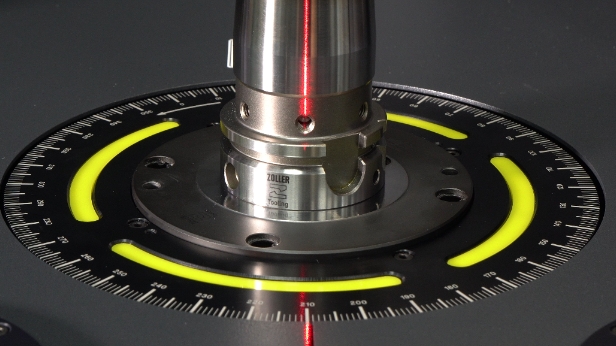

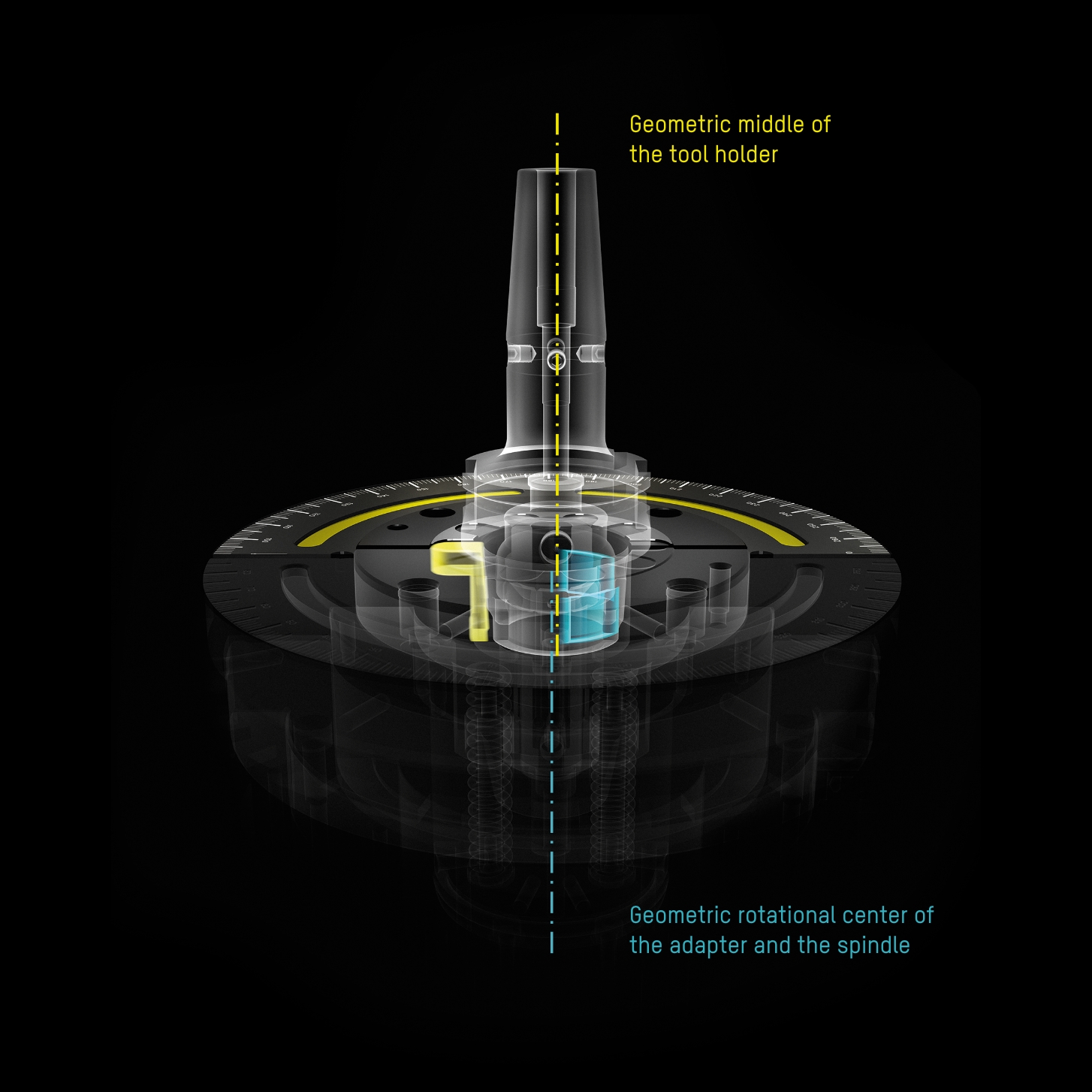

From the Center for the Highest Precision

Imbalanced tools are caused by an asymmetrical design and the resulting asymmetrical mass distribution. The ZOLLER »toolBalancer« solves like with like and relies on a deliberate center offset in the balancing adapter when measuring and balancing your tools.

The balancing adapter with center offset is designed with a two-point contact and a pressure element. These features enable a large and more measurable sensor signal and guarantee highly precise balancing results.

From the Center for the Highest Precision

Imbalanced tools are caused by an asymmetrical design and the resulting asymmetrical mass distribution. The ZOLLER »toolBalancer« solves like with like and relies on a deliberate center offset in the balancing adapter when measuring and balancing your tools.

The balancing adapter with center offset is designed with a two-point contact and a pressure element. These features enable a large and more measurable sensor signal and guarantee highly precise balancing results.

We Stand for Reliable Quality

100% made in Germany – that is our primary mission, and we work hard to ensure we achieve our goals. Thanks to an expansion of our production site in Pleidelsheim, Germany, our production is now even more efficient and economical.

The ZOLLER assembly – a team of specialized, competent employees from assembly and quality assurance ensure, day by day, that your »toolBalancer« reaches your production facility in a perfect condition. Your »toolBalancer« does not leave the line assembly until all our employees are 100% satisfied, and the device has the ZOLLER seal of quality. We are proud of this.

We Stand for Reliable Quality

100% made in Germany – that is our primary mission, and we work hard to ensure we achieve our goals. Thanks to an expansion of our production site in Pleidelsheim, Germany, our production is now even more efficient and economical.

The ZOLLER assembly – a team of specialized, competent employees from assembly and quality assurance ensure, day by day, that your »toolBalancer« reaches your production facility in a perfect condition. Your »toolBalancer« does not leave the line assembly until all our employees are 100% satisfied, and the device has the ZOLLER seal of quality. We are proud of this.