Inspection on autopilot

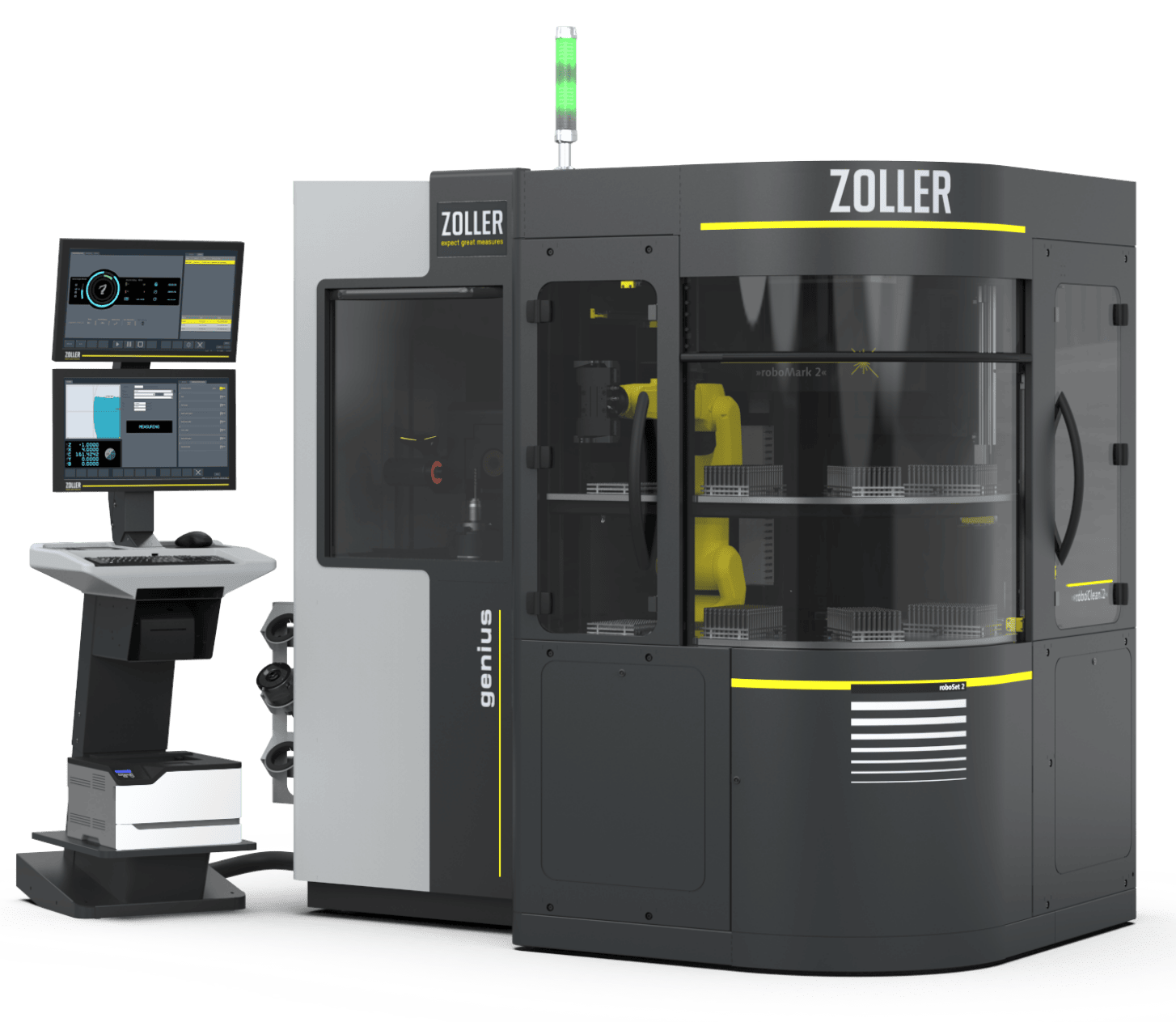

24/7 tool inspection and documentation with minimal manpower: »genius« plus »roboSet 2«

Focus your team's skills on production

Your in-house specialists are key to guaranteeing outstanding quality tools. But if these experts are tied up with tool inspection, the grinding shop and your entire production lose out on their knowledge.

Automate these processes with the »genius« plus »roboSet 2« and free up your team to focus on production. With these ZOLLER solutions, the manpower required for tool inspection and documentation is reduced by 83%.

Arrange 1:1 expert meeting

Measuring machine meets robotics

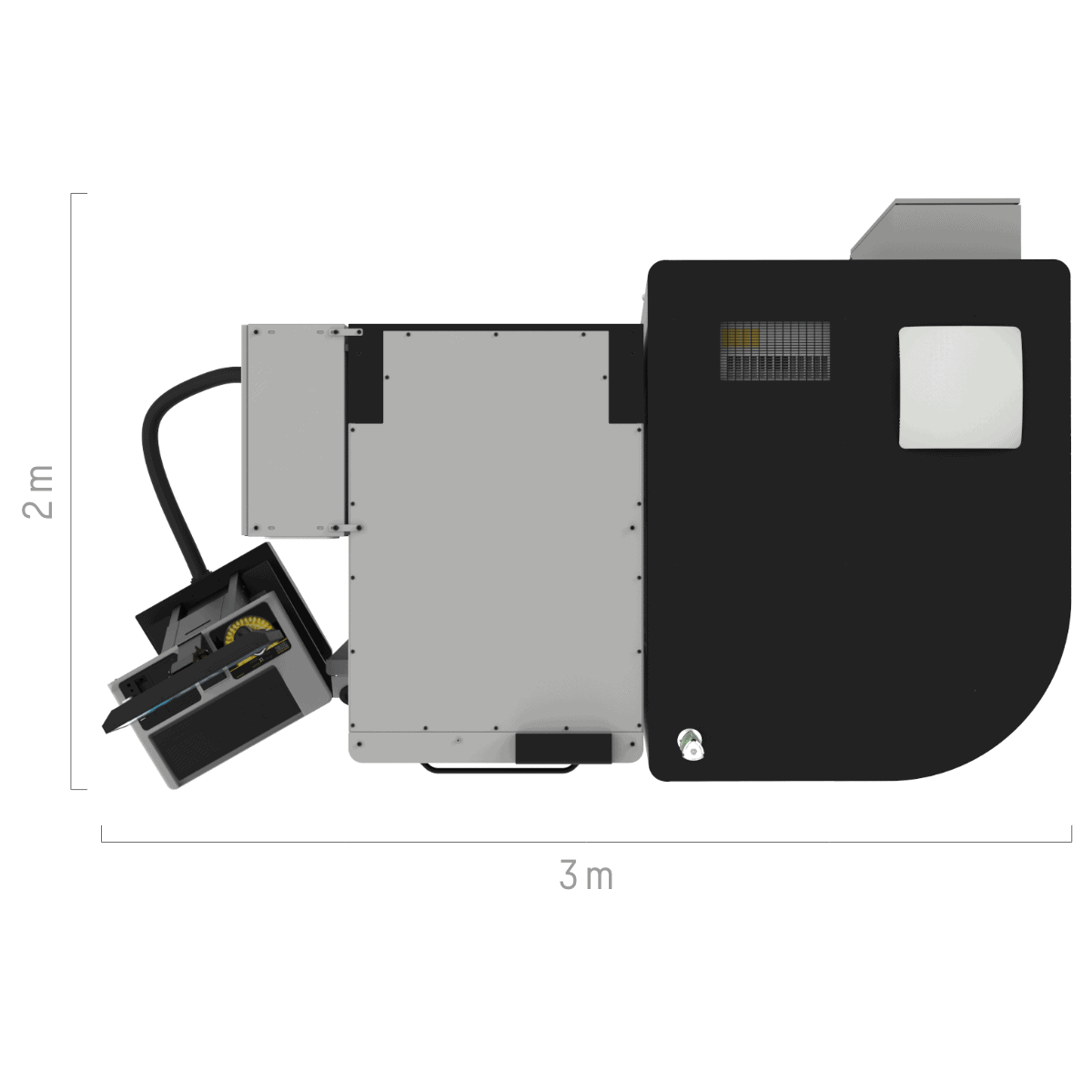

Premium measuring technology and the best robotics on the market work together seamlessly and have a shop floor footprint of less than 65 square feet. The »genius« measuring machine analyzes more than 100 parameters on standard and micro tools – all fully automatically.

Reduces labor costs by up to

83 %

Based on inspections in a three-shift operation with one employee per shift.