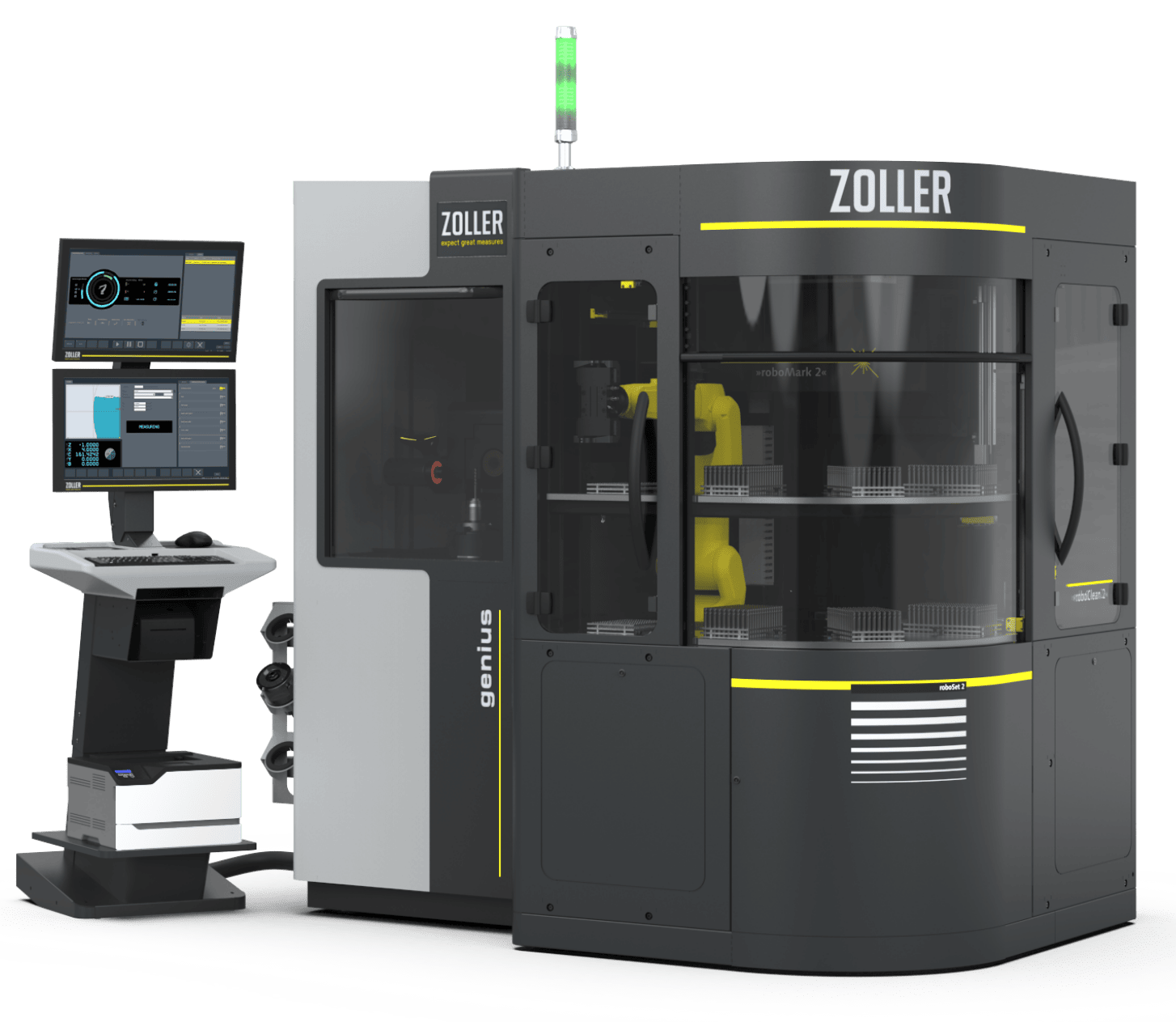

Clean and ready for testing

The »roboSet 2« provides ultrasonic and dry cleaning to guarantee every tool is free from microparticles, dust and organic cooling lubricants. No matter which ZOLLER measuring machine you combine with the »roboSet 2«, the tools will come out sparkling clean, creating the perfect conditions for tapping into the precise measuring power of ZOLLER.

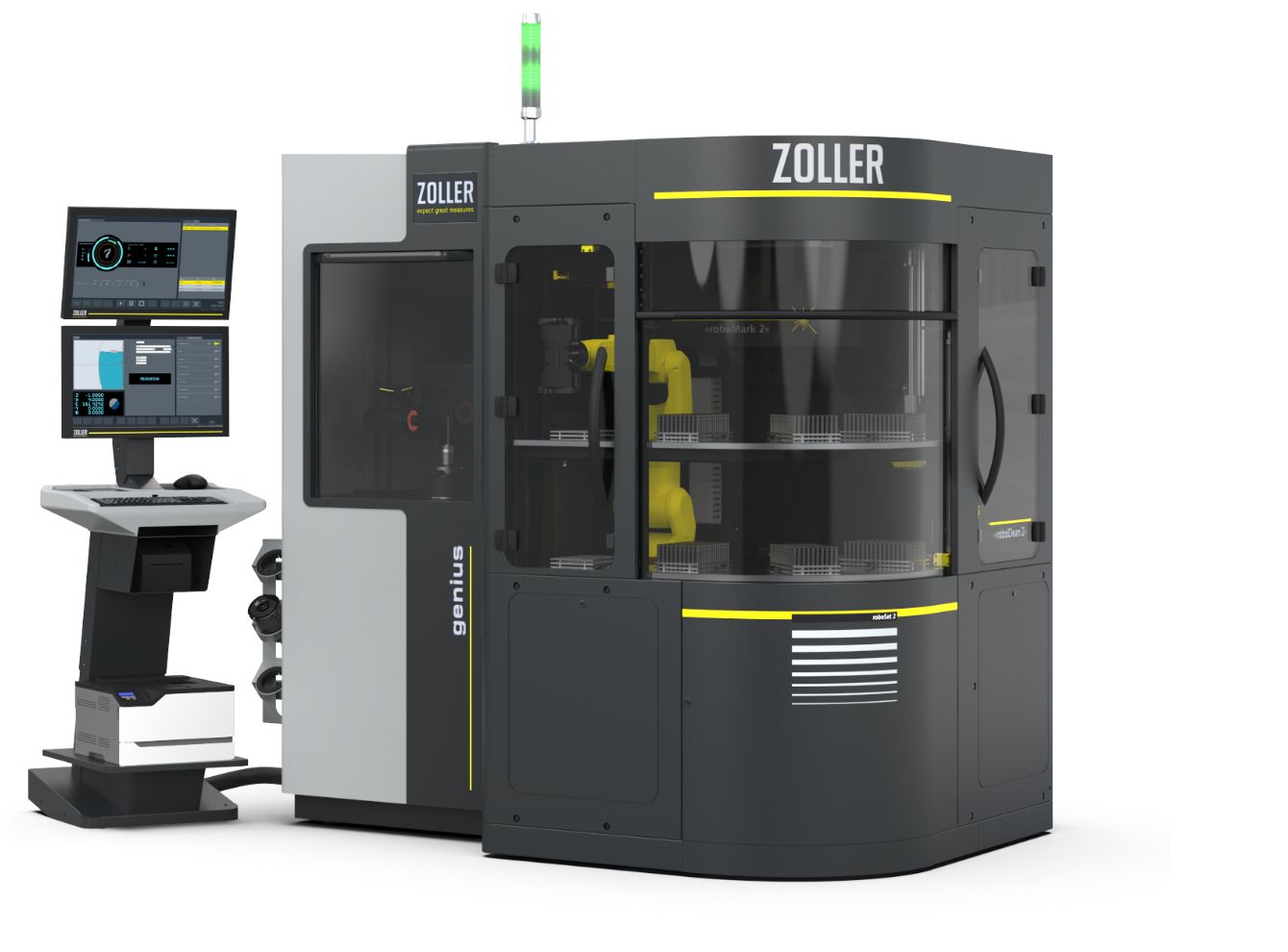

Clean and ready for testing

The »roboSet 2« provides ultrasonic and dry cleaning to guarantee every tool is free from microparticles, dust and organic cooling lubricants. No matter which ZOLLER measuring machine you combine with the »roboSet 2«, the tools will come out sparkling clean, creating the perfect conditions for tapping into the precise measuring power of ZOLLER.

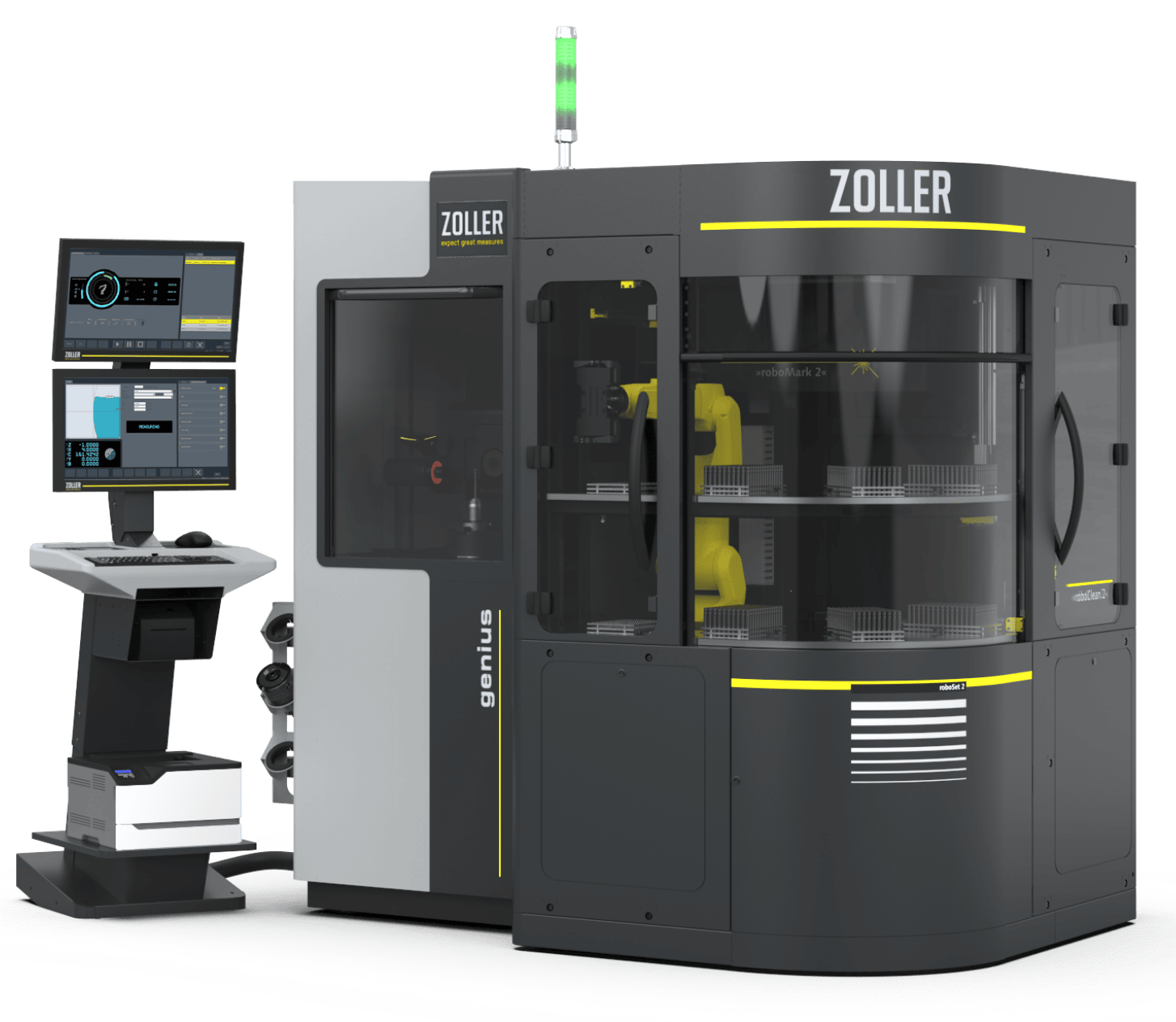

Mechanically decoupled

Major robotics actions take place inside the »roboSet 2« at the same time everything is still at the »genius« next door. To ensure the two neighbors co-exist in harmony, the »roboSet 2« was designed as a separate unit that is mechanically decoupled from the measuring machine, preventing vibrations and shocks from reaching the measurement technology.

Mechanically decoupled

Major robotics actions take place inside the »roboSet 2« at the same time everything is still at the »genius« next door. To ensure the two neighbors co-exist in harmony, the »roboSet 2« was designed as a separate unit that is mechanically decoupled from the measuring machine, preventing vibrations and shocks from reaching the measurement technology.

Software that guides automated inspection

With ZOLLER's »pilot 4.0« software, you define every step the »roboSet 2« should carry out for its next job. The software also impresses with intuitive operation, clear menus, large buttons and a customizable interface. You can plan and start tool inspections quickly and document data easily.

Pallet management

Cutting edge shape

Status display

Axis positions

Function keys