Options »powerShrink«

Flue gas suction device

The flue gas suction device reliably removes flue gases from the work area of the operator. The established and patented flue gas suction device above the induction coil was expanded by an integrated suction in the inside of the coil housing. The suction of the flue gases thus happens directly where they are produced. The filter unit finds a safe place in the table.

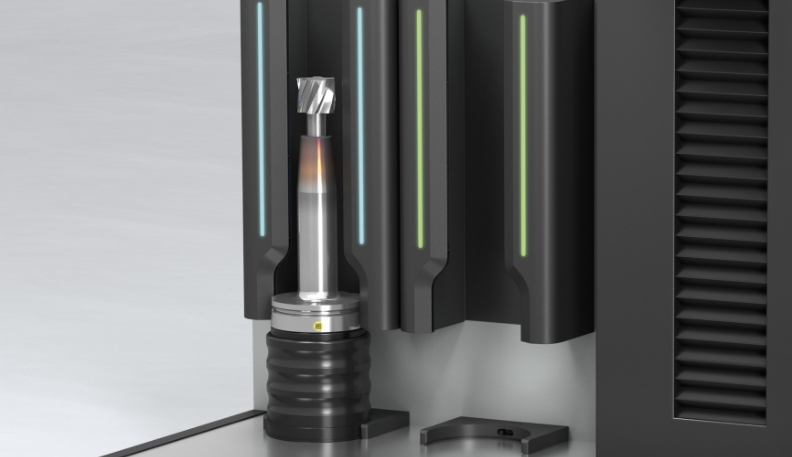

Air cooling »zStream«

With ZOLLER's air cooling »zStream« you obtain maximal flexibility and protection with the cooling of your shrink fit tool holder, independently of its contour or diameter. In addition, your shrink-clamping tools are cooled consistently and safely across their entire length – without the risk of being damaged. »zStream« is also ideally suited for cooling placed down tools. »powerShrink« is available with two or three separate cooling places* for parallel, effective use.

*two cooling spaces for .powerShrink 400., three cooling spaces for .powerShrink 600.

Length setting »eQset«

The integrated length setting system is used to set the overall length or projection length and for the tool exchange. The pneumatically-activated quick adjustment and fine adjustment by hand wheel allow a fast, ergonomic and precise position of the probe head to the required height.

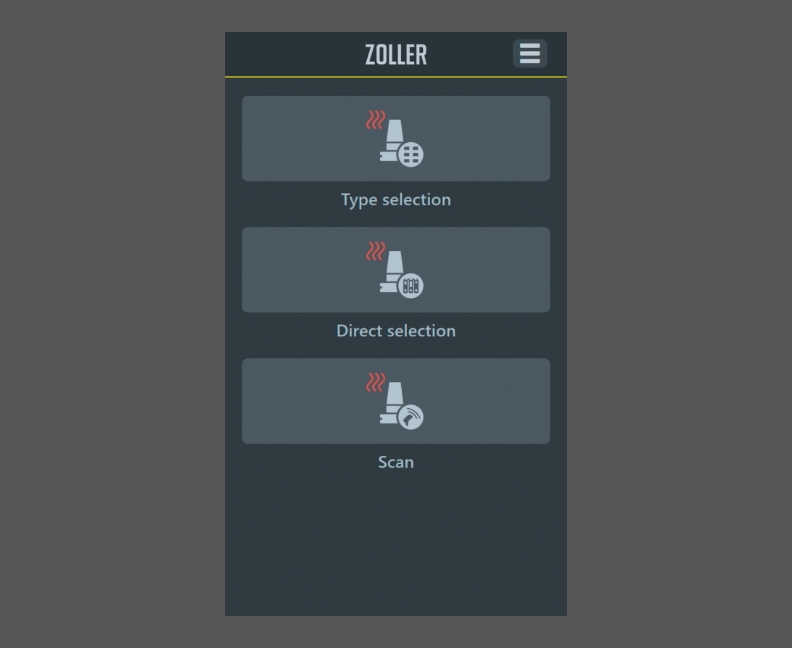

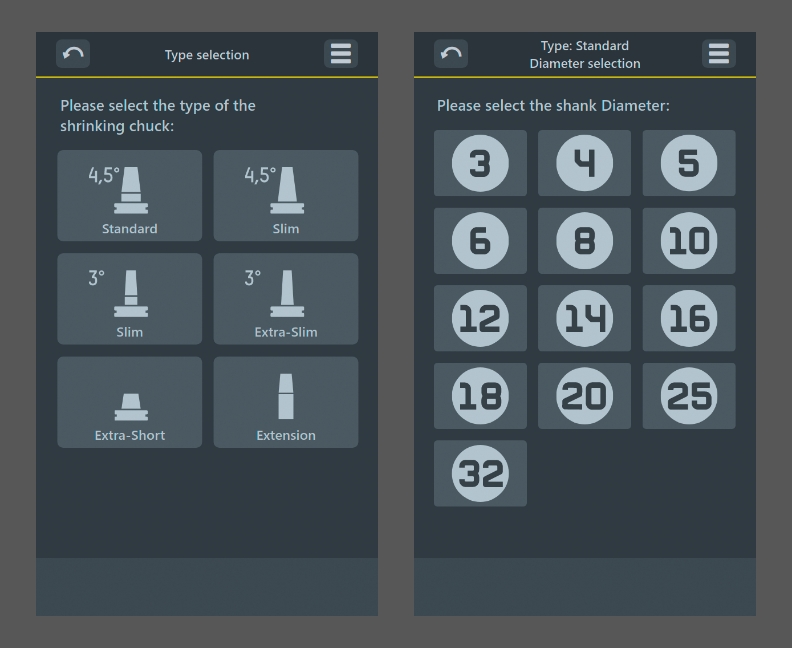

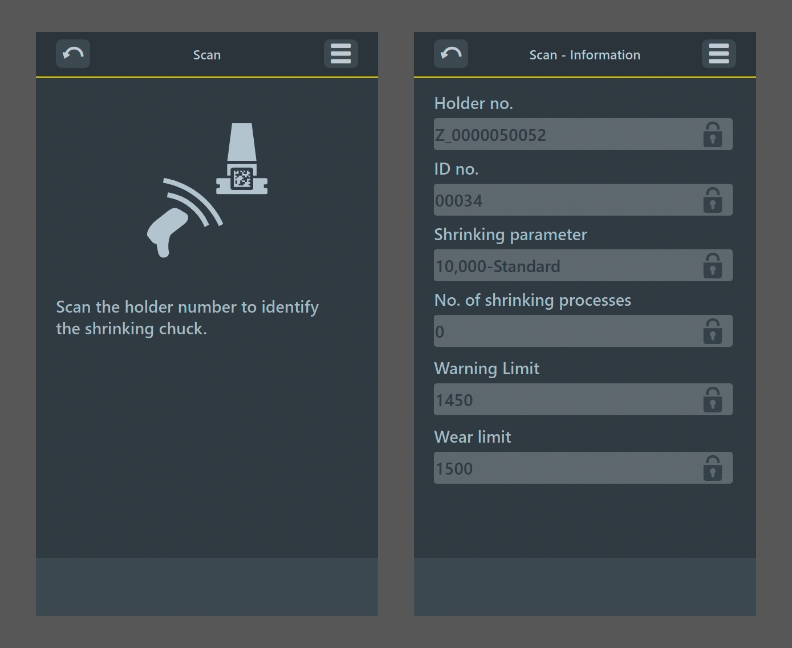

Scan function, incl. hand scanner

The »pilot« software scan function, combined with the hand scanner, enables the reliable selection of the appropriate shrink parameter by scanning the holder number on the shrink-holding fixture. Regardless of the manufacturer, all shrink-clamping chucks with a DataMatrix code (e. g., ZOLLER »idLabel«, ZOLLER »idChip«) are supported.

In the »pilot« software, each heating process can be counted per shrink-clamping chuck. In addition, a warning and wear limit, in relation to the permissible heating operations, can be stored.

Membrane keypad for »powerShrink 400«

Alternatively, the diameter selection (for shrink-clamping chuck according to DIN 69882-8) on the »powerShrink 400« can be selected quickly and simply via an oil- and dirt-resistant, workshopcompatible and durable membrane keypad.

Set up table for »powerShrink 400«

As an alternative to installation on a workbench, the »powerShrink 400« can be positioned on a set-up table with ergonomically optimal working height. This provides a tidy place for the cooler and flue gas suction device. The table is optionally available with sturdy rollers and an ergonomic handle, to allow variable positioning of the »powerShrink 400«.

Accessories »powerShrink«

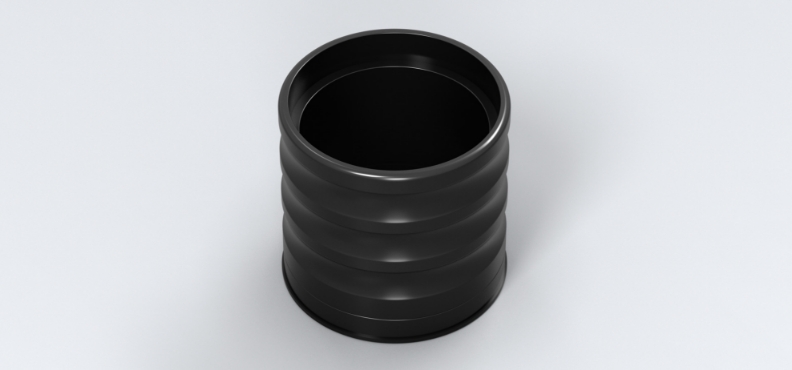

Mounting pot

With your »powerShrink«, you get a default mounting pot. Optionally, additional units can be ordered for parallel heating and cooling. The bearing surface is perfectly matched to the mounting pot and enables a comfortable and quiet shift.

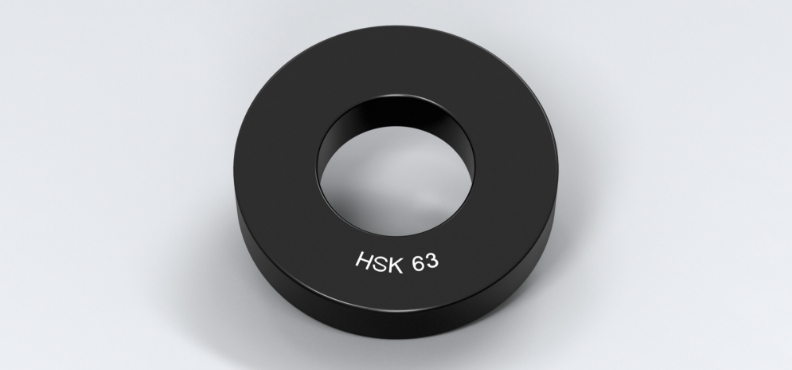

Mounting rings

The different mounting rings allow flexible retooling between different mounting interfaces. For all common tool-holding fixture types and sizes up to SK 50, HSK 100 and PSC 10.

Special cooling adapter

Cooling adapter for specialized shrink fit tool holder forms and sizes (e. g., also for D3 mm to D5 mm). Matching for cooling bells D14 mm to D16 mm or D25 mm to D32 mm.

Compartments

Storage board for mounting rings and special cooling adapter

The storage board provides space for storing four mounting rings and six size I special cooling adapters or three size I and size II special cooling adapters.

Tool tray

For depositing shank tools at the shrinking workstation. The position of the tray can be freely selected by the operator.

Tray for cleaning brushes

For storing the cleaning brushes, there is a tray with all brush diameters, which can be attached to the machine via magnets, and at any position. The brushes for cleaning the locating bore of shrink fit tool holders are also available from ZOLLER – for shaft diameters D3 mm to D32 mm, optionally made of brass or plastic.

Split screening plates with tray

For unclamping of placed down tools, optionally, a set of screening plates (5 pieces) in split version including the corresponding disc tray can be ordered.

Coil operating handle

For optimal, user-friendly operation, the operating handle, which is mounted on the left as a default, can optionally be selected to be mounted on the right side or on both sides. Each control handle is equipped with two function buttons – for moving the coil and activating the heating process.

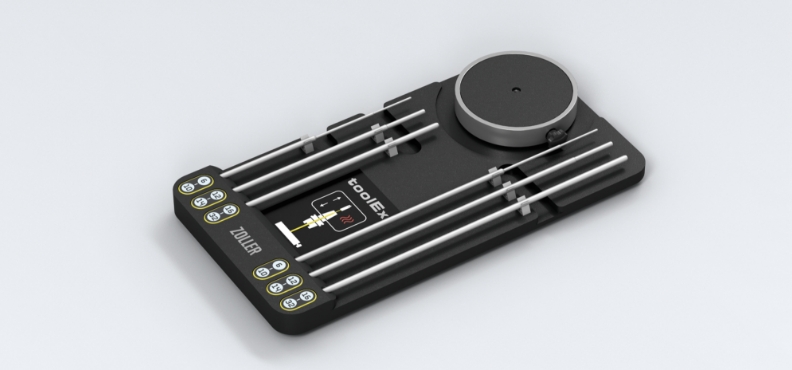

Unclamping device »toolEx«

»toolEx« supports you when removing tools from the shrink-clamping chuck, which cannot be removed by hand or with pliers, such as broken tools. The set includes a holder and six ejector rods.

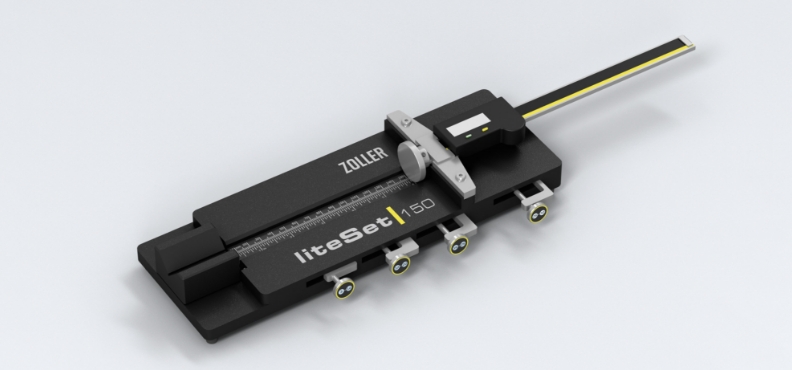

Length setting »liteSet«

With the »liteSet« you set the projecting length of the tool to be shrink-clamped. The maximum cantilever length is 150 mm. The set includes four clamping prisms for shaft diameters D3 mm to D32 mm.