»ace« spindle: quick exchange

The »ace« spindle records any adapter tool posts directly and without play via its ball bushing. You can insert the appropriate tool holders into the adapter tool posts and clamp them power-operated just like in the machine tool. The attachment holder is changed in 10 seconds with an accuracy of < 1 µm. The ROD rotation sensor enters the exact position of the C axis.

»ace« spindle: quick exchange

The »ace« spindle records any adapter tool posts directly and without play via its ball bushing. You can insert the appropriate tool holders into the adapter tool posts and clamp them power-operated just like in the machine tool. The attachment holder is changed in 10 seconds with an accuracy of < 1 µm. The ROD rotation sensor enters the exact position of the C axis.

Optics with industrial camera

A keen eye for detail: the high-quality lens has additional lenses and enters every detail - with optional higher resolution.

Optics with industrial camera

A keen eye for detail: the high-quality lens has additional lenses and enters every detail - with optional higher resolution.

Automated measurement

You always receive precise measurement data for your tools, regardless of the operator. With CN control, autofocus and the intuitive »pilot 4.0« device software, »venturion 450« brings automated tool measurement to your production.

Automated measurement

You always receive precise measurement data for your tools, regardless of the operator. With CN control, autofocus and the intuitive »pilot 4.0« device software, »venturion 450« brings automated tool measurement to your production.

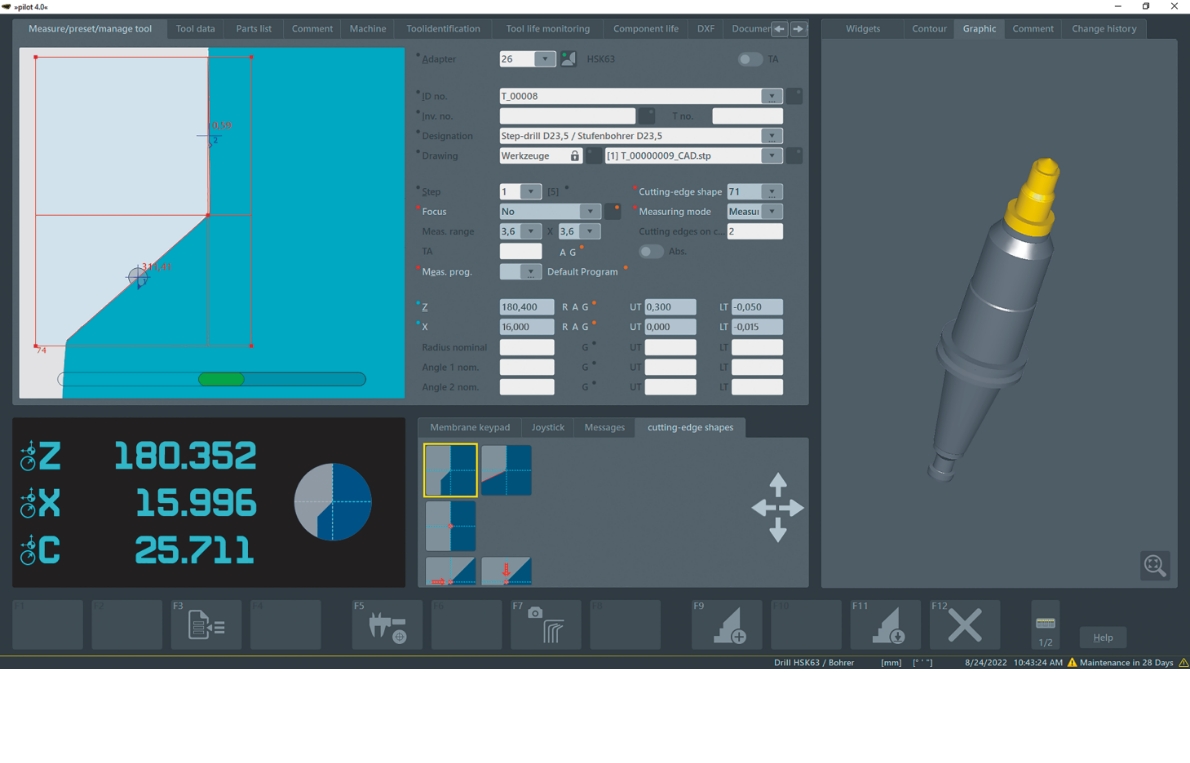

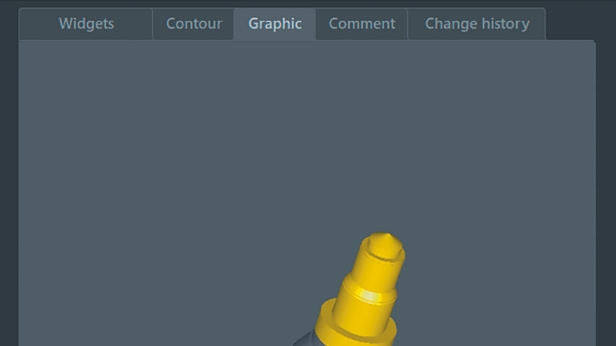

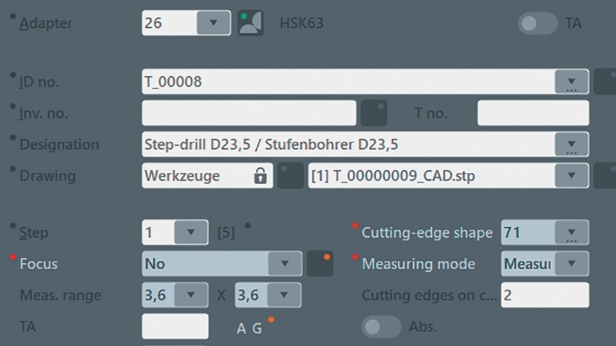

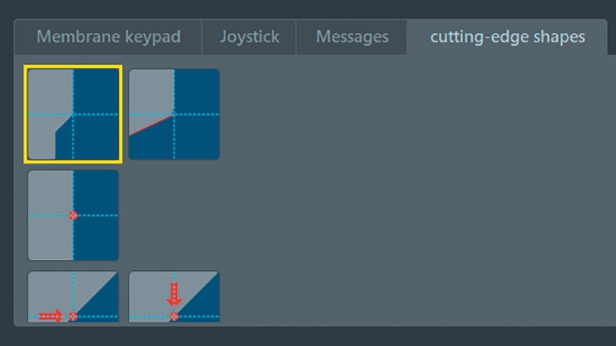

»pilot 4.0« – the software that sets the standard worldwide

»pilot 4.0« is the user-friendly device software and image processing of your »smile 420« and »venturion 450«. With the intuitive graphic user guidance, you can quickly and safely obtain precise measurement results and production-relevant tool data. Even complex measuring tasks can be completed immediately. It is not for nothing that »pilot 4.0« applies as the world's unrivalled benchmark for tool settings, measurement and testing.

Tool-specific information

Adapter management

Cutting-edge shapes

Function buttons

Current camera image

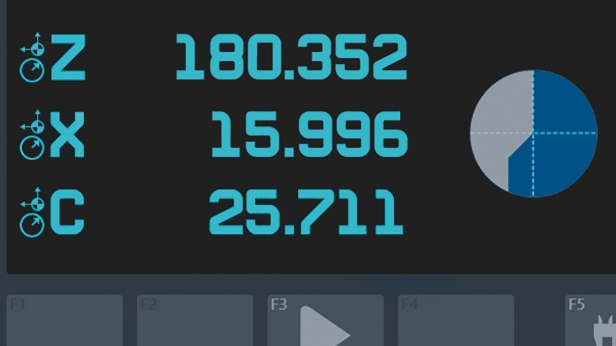

Current position information