Measure changes everything

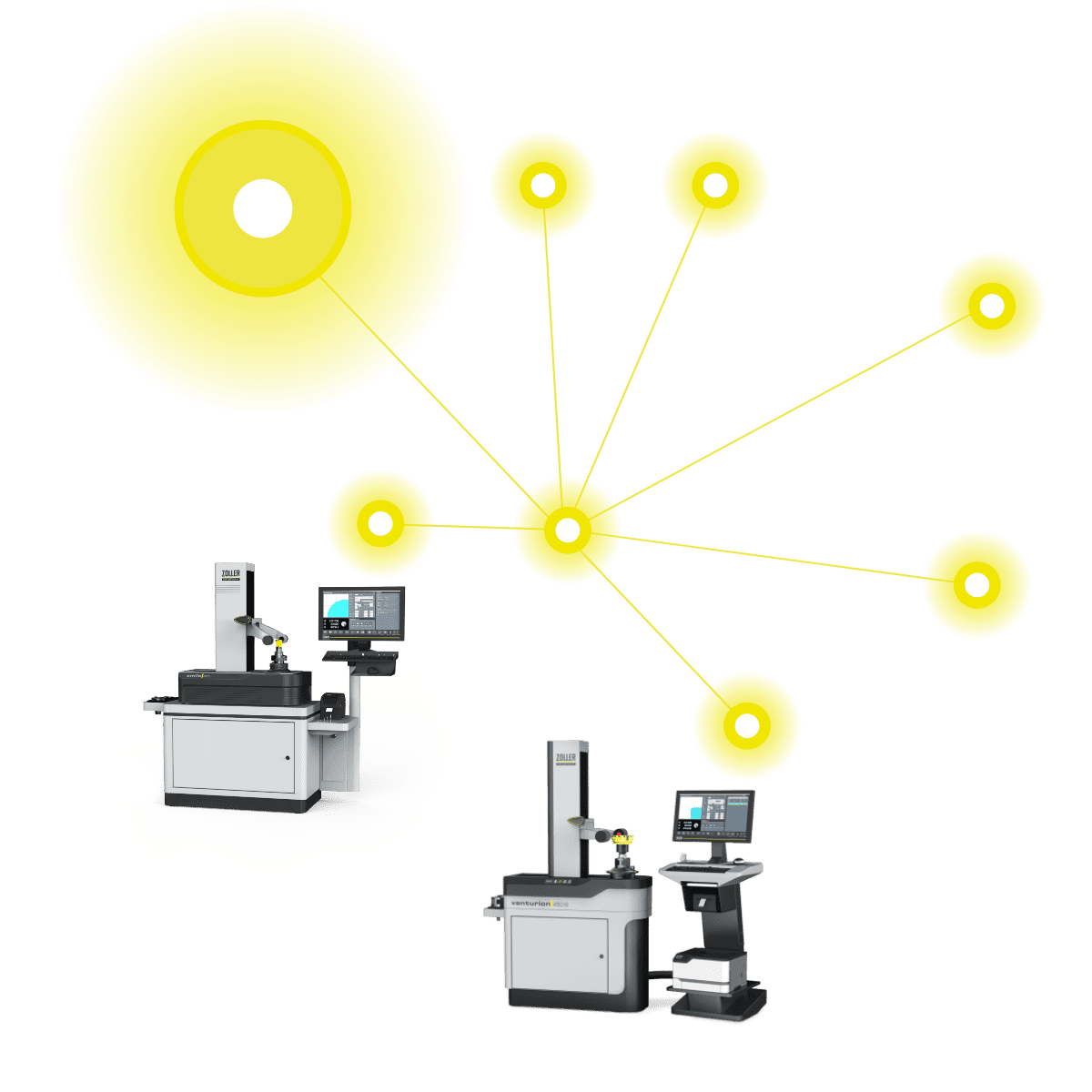

With »smile 420« and »venturion 450« you can turn potential into economic success.

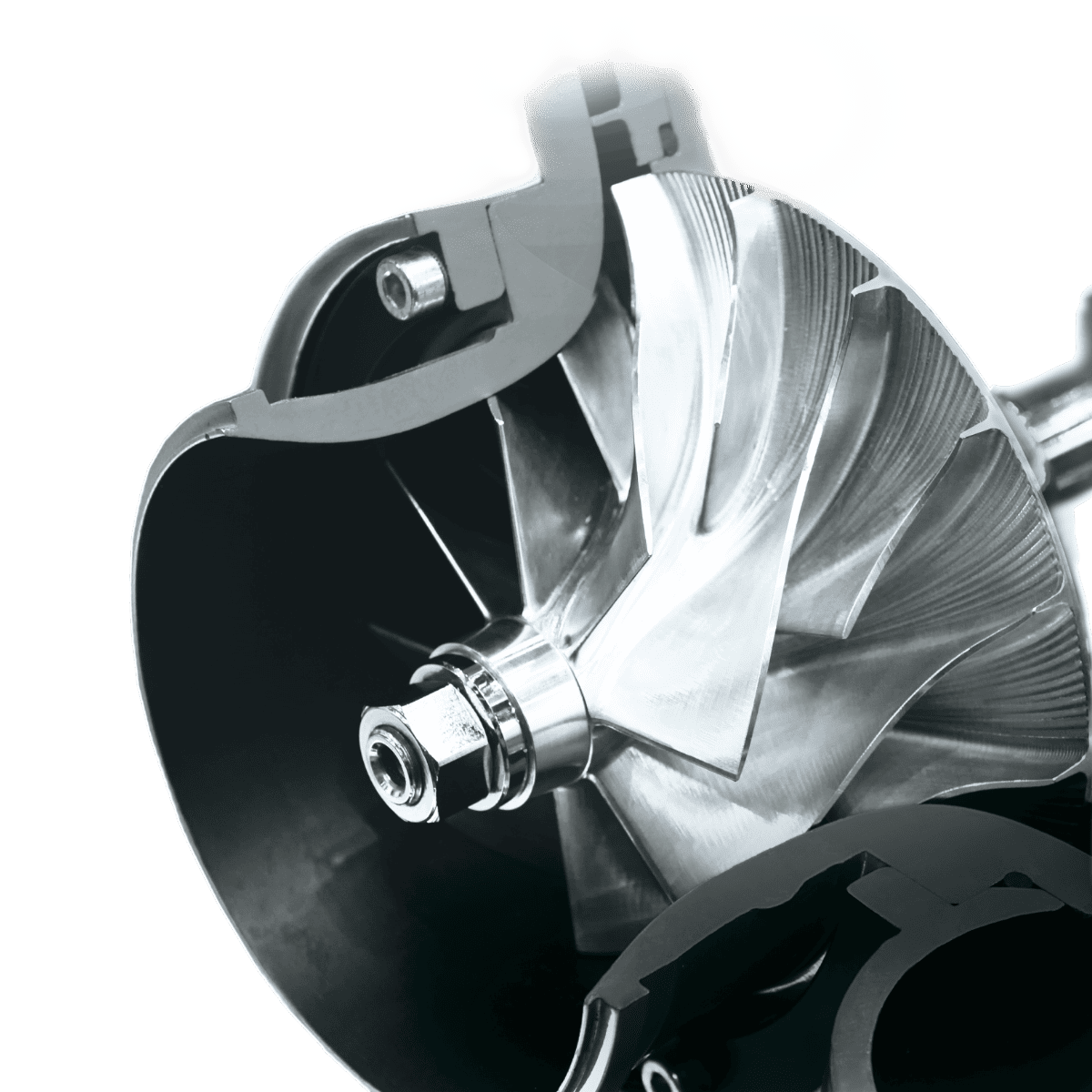

Tool as a success factor

When competition is tough, potential can no longer be allowed to lie dormant. Only if you measure your tools with exact precision will you be able to fully utilise their potential and that of your CNC machines.

With »smile 420« or »venturion 450«, your tools are excellently measured when they arrive at the machine. We are certain that this will have a positive impact on your production.

Arrange 1:1 expert meeting

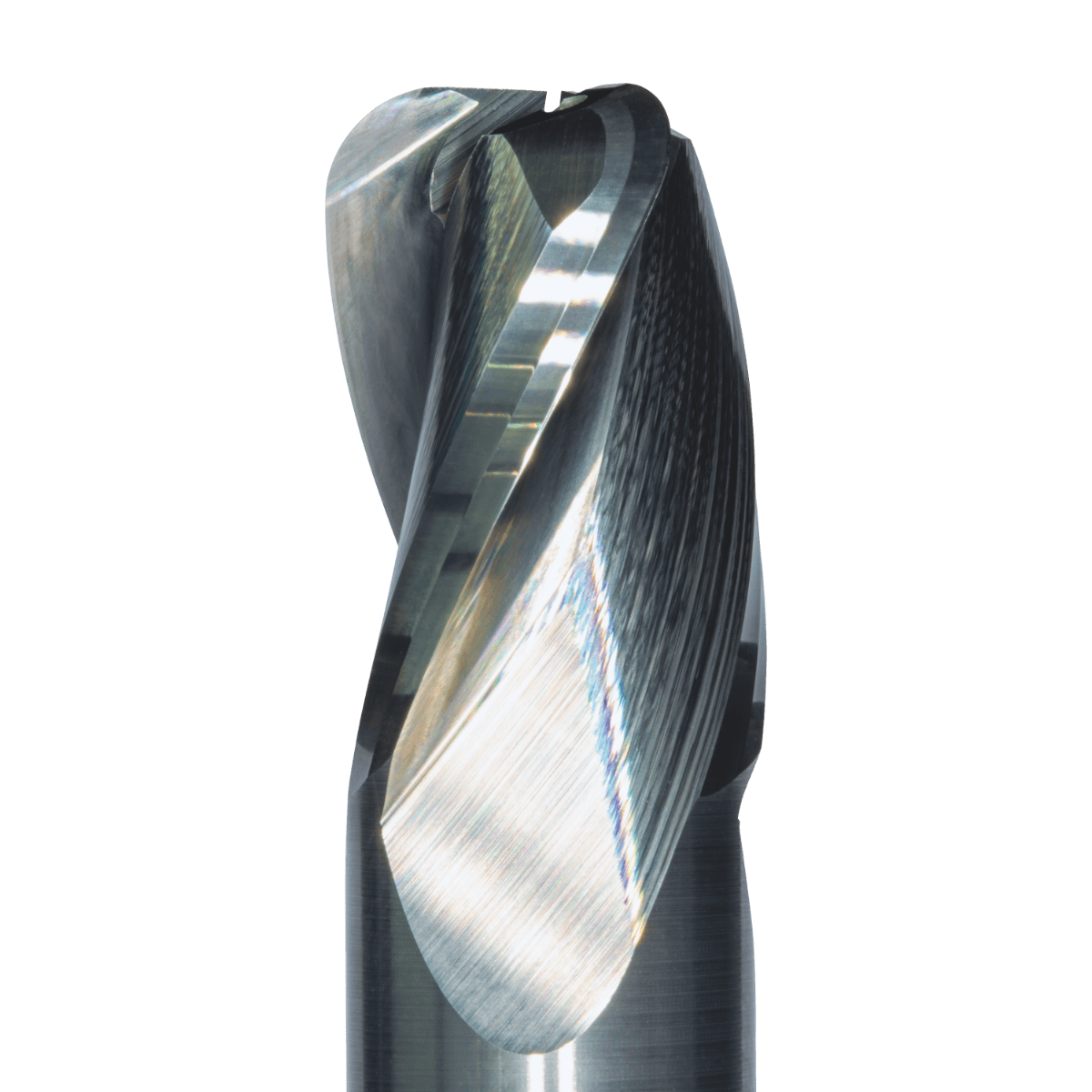

Extend tool life

Tool geometries and dimensions are translated into precise tool data. The CNC machine uses the tool in an efficient and wear-friendly manner.

Reduce setup times

Measurement on the presetting and measuring machine is faster and more precise than measurement in the machine. Setup times are reduced because tools arrive at the machine ready to go.

Scalable savings potential per CNC machine per year*:

15000 €

* Calculated for 20 tool changes per 3 min. changeover time, 200 working days/year and one shift per day, machine hour €75 each.