Technical Data

»smartCheck 600«

»smartCheck 800«

23.62" (600 mm)

Maximum tool length Z

23.62" (600 mm)

Maximum tool length Z

22.04"/23.62"/25.98"/31.49" (560/600/660/800 mm)

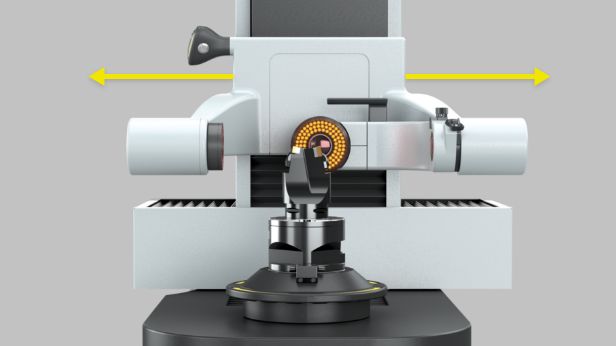

Maximum tool diameter D

33.86"/39.37" (860/1000 mm)

Maximum tool diameter D

2.55"/3.34" (65/85 mm)

Maximum snap gauge diameter d

3.34" (85 mm)

Maximum snap gauge diameter d

± 3.93" (± 100 mm)

Travel range Y-axis

—

3–4

Number of axes

3–4

Number of axes

~ 76.22" (~ 1936 mm)

Height H1

~ 76.22" (~ 1936 mm)

Height H1

31.49" (800 mm)

Maximum tool length Z

31.49" (800 mm)

Maximum tool length Z

22.04"/23.62"/25.98"/31.49" (560/600/660/800 mm)

Maximum tool diameter D

33.86"/39.37" (860/1000 mm)

Maximum tool diameter D

2.55"/3.34" (65/85 mm)

Maximum snap gauge diameter d

3.34" (85 mm)

Maximum snap gauge diameter d

± 3.93" (± 100 mm)

Travel range Y-axis

—

3–4

Number of axes

3–4

Number of axes

~ 84.09" (~ 2136 mm)

Height H1

~ 84.09" (~ 2136 mm)

Height H1

39.37" (1000 mm)

Maximum tool length Z

39.37" (1000 mm)

Maximum tool length Z

22.04"/23.62"/25.98"/31.49" (560/600/660/800 mm)

Maximum tool diameter D

33.86"/39.37" (860/1000 mm)

Maximum tool diameter D

2.55"/3.34" (65/85 mm)

Maximum snap gauge diameter d

3.34" (85 mm)

Maximum snap gauge diameter d

± 3.93" (± 100 mm)

Travel range Y-axis

—

3–4

Number of axes

3–4

Number of axes

~ 91.96" (~ 2336 mm)

Height H1

~ 91.96" (~ 2336 mm)

Height H1

47.24" (1200 mm)

Maximum tool length Z

47.24" (1200 mm)

Maximum tool length Z

22.04"/23.62"/25.98"/31.49" (560/600/660/800 mm)

Maximum tool diameter D

33.86"/39.37" (860/1000 mm)

Maximum tool diameter D

2.55"/3.34" (65/85 mm)

Maximum snap gauge diameter d

3.34" (85 mm)

Maximum snap gauge diameter d

± 3.93" (± 100 mm)

Travel range Y-axis

—

3–4

Number of axes

3–4

Number of axes

~ 99.84" (~ 2536 mm)

Height H1

~ 99.84" (~ 2536 mm)

Height H1

Configuration »smartCheck 600«

Axes

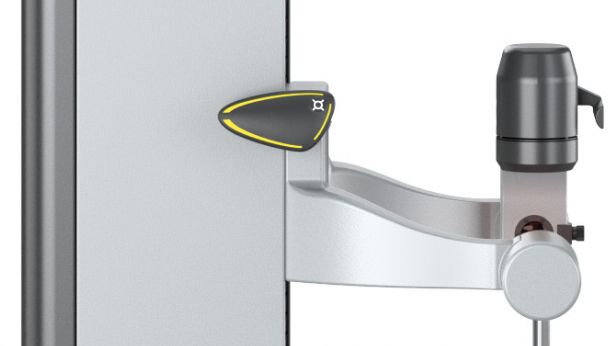

One-hand control handle »eQ«

Base model

CNC drive (Z, X)

Base model

Fine adjustment/handwheels (Z, X)

optional

Angle measuring system C-axis

Base model

CNC/autofocus

Base model

CNC/Y-axis

optional

CNC/swiveling optics carrier (A)

optional

Electronics

24" TFT color monitor with software »pilot 4.0«

Base model

Additional 17"satellite monitor

optional

Integrated control unit with keyboard/mouse

optional

Separate control unit »cockpit«

Base model

Spindle

High-precision spindle SK 50/Vacuum

optional

High-precision spindle »ace« size 1

Base model

High-precision spindle »ace« size 2

optional

Tailstock

Pneumatic counter center

optional

Camera/sensors configuration

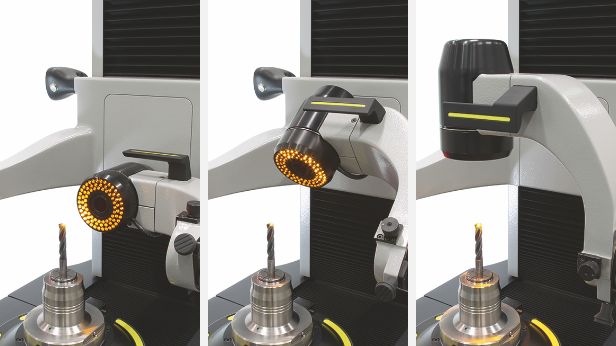

Transmitted light camera HR50, BF approx. 0.28" x 0.26" (7.3 x 6.7 mm2)

Base model

Transmitted light camera HR50 1:1, BF approx. 0.15" x 0.14" (4.0 x 3.6 mm2)

optional

Transmitted light camera HR70 1:1, BF approx. 0.15" x 0.14" (4.0 x 3.6 mm2)

optional

Transmitted light camera 5 Mpx, BF approx. 0.17" x 0.15" (4.4 x 4.0 mm2)

optional

Transmitted light camera WF, BF approx. 0.61" x 0.55" (15.5 x 14.1 mm2)

optional

Incident light camera, BF approx. 0.17" x 0.15" (4.4 x 4.0 mm2)

Base model

Cutting edge inspection LED incident light

Base model

Premium tool inspection

Base model

Stable table

Integrated

Base model

Tool identification

RFID Manual »mslz«

optional

RFID Semi-automatic/drive slot

optional

RFID Automatic/drive slot

optional

RFID Automatic/head bolt

optional

Code scanner Manual/drive slot

optional

Code scanner Automatic/drive slot

optional

Configuration »smartCheck 800«

Axes

One-hand control handle »eQ«

Base model

CNC drive (Z, X)

Base model

Fine adjustment/handwheels (Z, X)

optional

Angle measuring system C-axis

Base model

CNC/autofocus

Base model

CNC/swiveling optics carrier (A)

optional

Electronics

24" TFT color monitor with software »pilot 4.0«

Base model

Additional 17"satellite monitor

optional

Integrated control unit with keyboard/mouse

optional

Separate control unit »cockpit«

Base model

Spindle

High-precision spindle SK 50/Vacuum

optional

High-precision spindle »ace« size 1

Base model

High-precision spindle »ace« size 2

optional

Tailstock

Pneumatic counter center

optional

Camera/sensors configuration

Transmitted light camera HR50, BF approx. 0.28" x 0.26" (7.3 x 6.7 mm2)

Base model

Transmitted light camera HR50 1:1, BF approx. 0.15" x 0.14" (4.0 x 3.6 mm2)

optional

Transmitted light camera HR70 1:1, BF approx. 0.15" x 0.14" (4.0 x 3.6 mm2)

optional

Incident light camera, BF approx. 0.17" x 0.15" (4.4 x 4.0 mm2)

Base model

Cutting edge inspection LED incident light

Base model

Premium tool inspection

Base model

Stable table

Integrated

Base model

Tool identification

RFID Manual »mslz«

optional

RFID Semi-automatic/drive slot

optional

RFID Automatic/drive slot

optional

RFID Automatic/head bolt

optional

Code scanner Manual/drive slot

optional