We Stand for Smart Progress

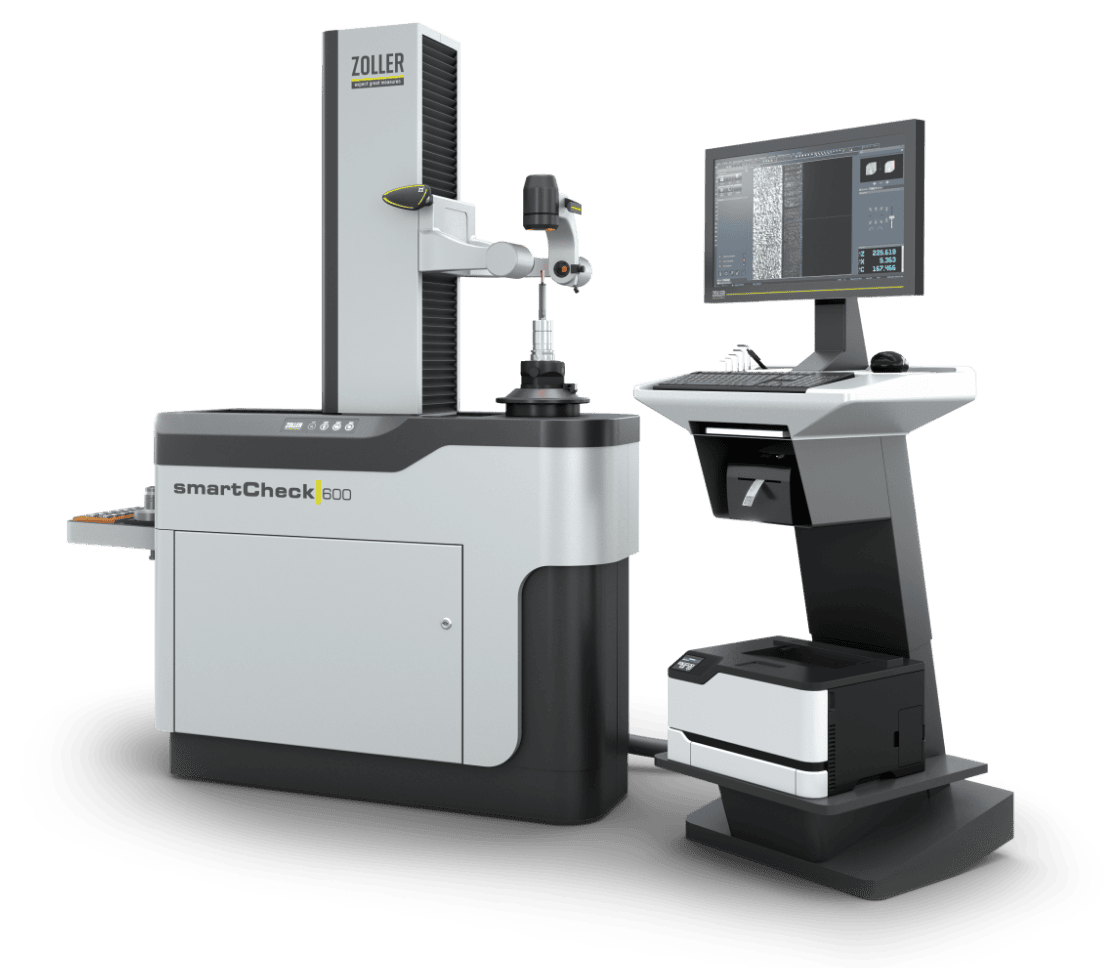

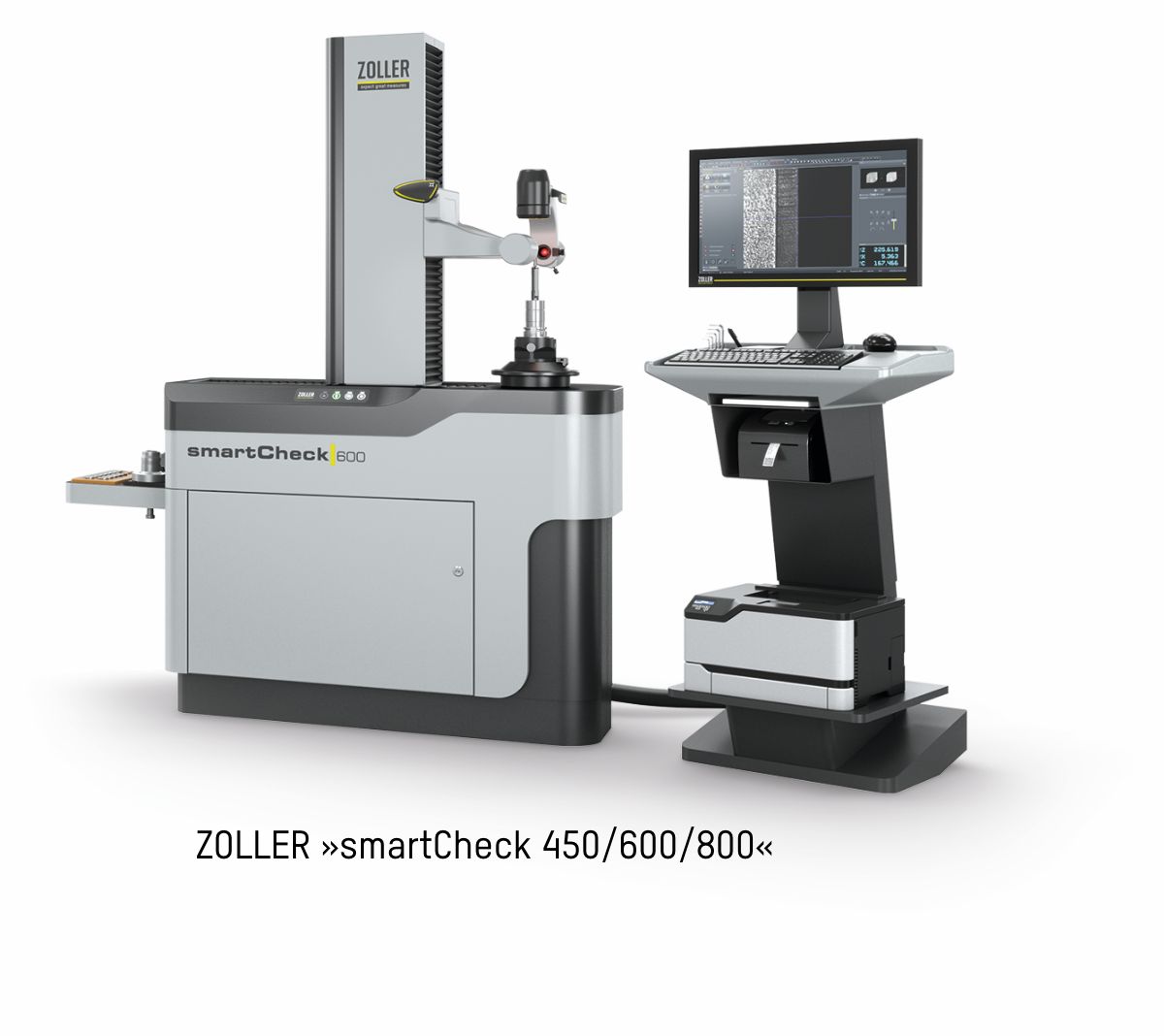

Are you looking for a powerful universal inspection and measuring device for your cutting tools? ZOLLER offers its customers various solutions for checking tools in the most economical way before and after sharpening – unbeatable, indispensable and 100% convincing.

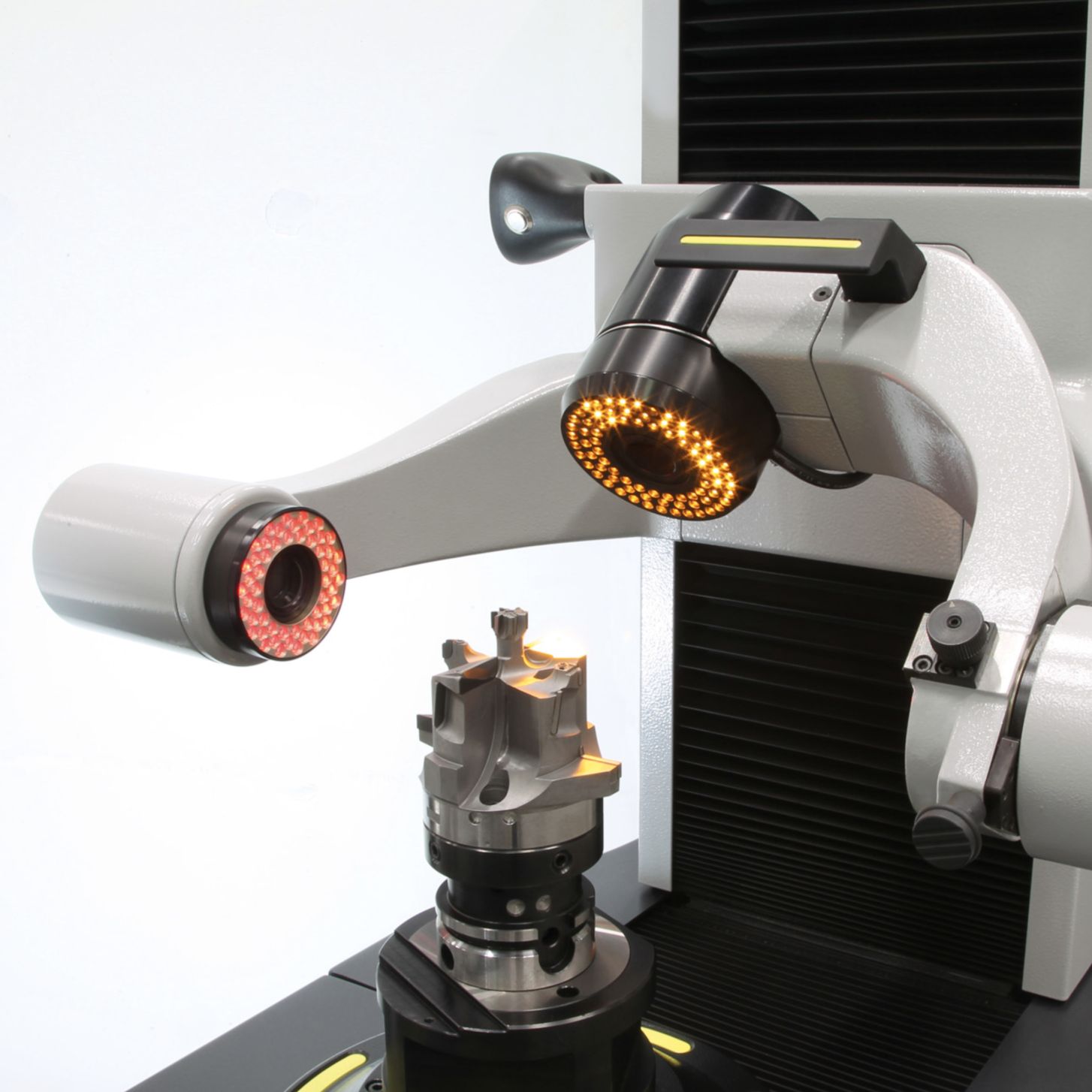

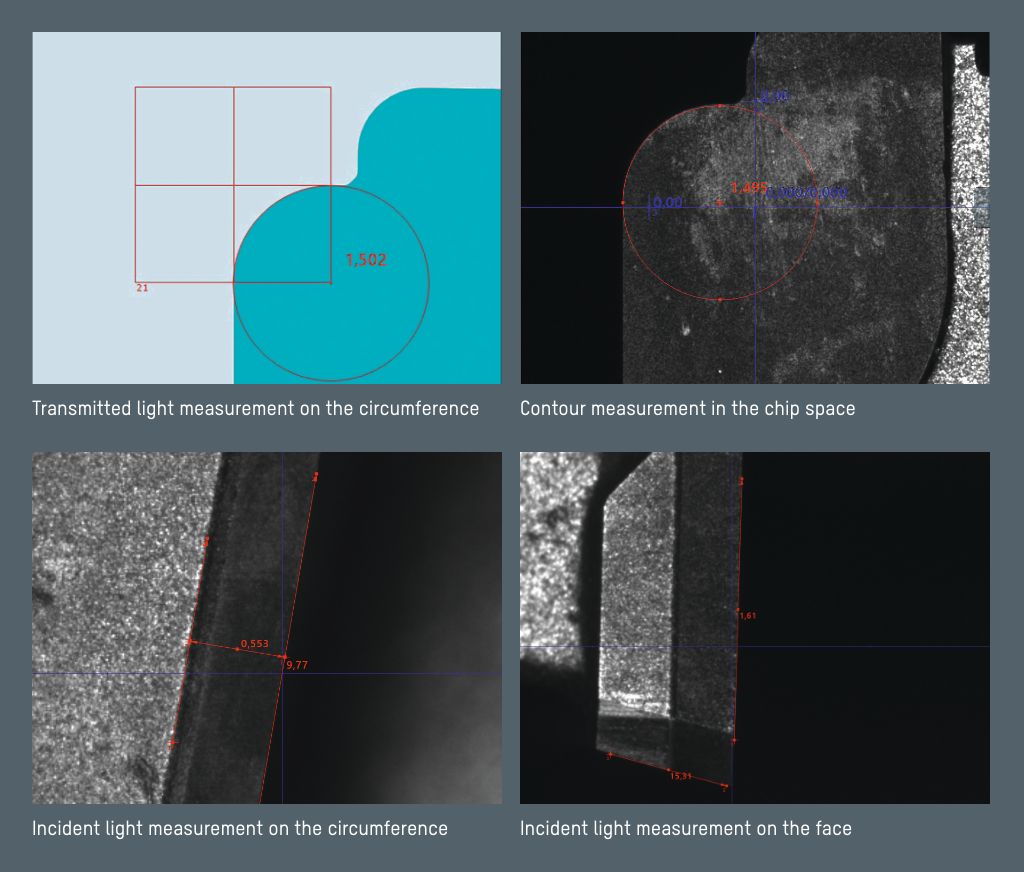

With the ZOLLER »smartCheck«, you can inspect and measure your tools and grinding wheels right next to the machine. Even when inspecting your tools before the resharpening process, you can achieve a highprecision quality check.

We Stand for Smart Progress

Are you looking for a powerful universal inspection and measuring device for your cutting tools? ZOLLER offers its customers various solutions for checking tools in the most economical way before and after sharpening – unbeatable, indispensable and 100% convincing.

With the ZOLLER »smartCheck«, you can inspect and measure your tools and grinding wheels right next to the machine. Even when inspecting your tools before the resharpening process, you can achieve a highprecision quality check.

We Stand for Reliable Quality

100% made in Germany – that is our primary mission, and we work hard to ensure we achieve our goals. Thanks to an expansion of our production site in Pleidelsheim, Germany, our production is now even more efficient and economical.

The ZOLLER assembly – a team of specialized, competent employees from assembly and quality assurance ensure, day by day, that your »smartCheck« reaches your production facility in perfect condition. It only leaves the assembly line until all our employees are 100% satisfied, and the machine has the ZOLLER seal of quality.

We are proud of this.

We Stand for Reliable Quality

100% made in Germany – that is our primary mission, and we work hard to ensure we achieve our goals. Thanks to an expansion of our production site in Pleidelsheim, Germany, our production is now even more efficient and economical.

The ZOLLER assembly – a team of specialized, competent employees from assembly and quality assurance ensure, day by day, that your »smartCheck« reaches your production facility in perfect condition. It only leaves the assembly line until all our employees are 100% satisfied, and the machine has the ZOLLER seal of quality.

We are proud of this.