Check your threading tools

With the »smartCheck«, you can check threading tools for quality and wear and tear. The optic carrier can be swiveled with the high-definition industrial camera for this purpose.

Check your threading tools

With the »smartCheck«, you can check threading tools for quality and wear and tear. The optic carrier can be swiveled with the high-definition industrial camera for this purpose.

Turn on the right light

When tools facets join at shallow angles, conventional incident light has limits, often providing too little contrast in the image. With the »smartCheck«, you can direct the light to the right location by activating the LEDs in separate segments. Another effect is the image quality increases with polished tools.

You'll see!

Turn on the right light

When tools facets join at shallow angles, conventional incident light has limits, often providing too little contrast in the image. With the »smartCheck«, you can direct the light to the right location by activating the LEDs in separate segments. Another effect is the image quality increases with polished tools.

You'll see!

Get up close

The built-in camera of the »smartCheck« magnifies tool cutting edges up to 50 times — more than enough for the inspection of small tools. The camera can even accommodate heavy equipment, handling tool length and diameter can be up to 600 mm.

Get up close

The built-in camera of the »smartCheck« magnifies tool cutting edges up to 50 times — more than enough for the inspection of small tools. The camera can even accommodate heavy equipment, handling tool length and diameter can be up to 600 mm.

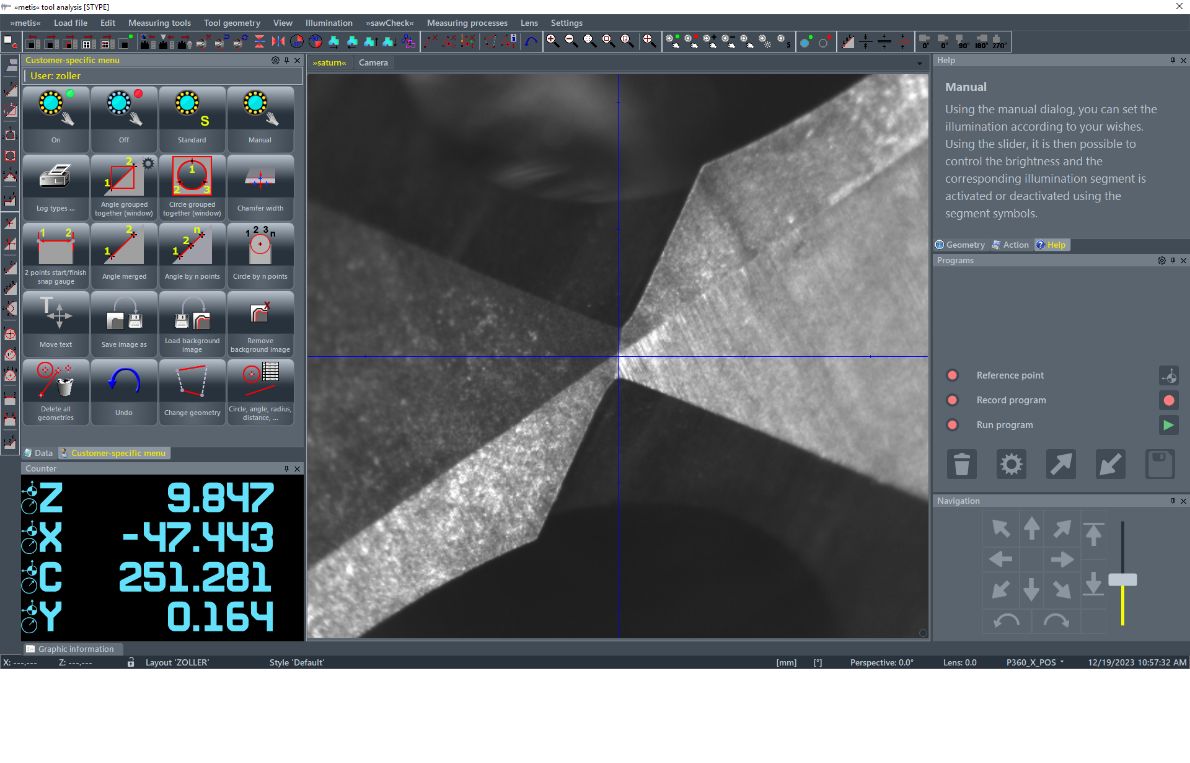

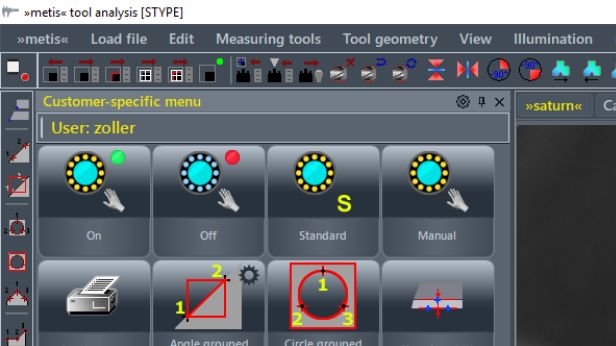

Software: »pilot 4.0« and »metis«

The »pilot 4.0« is the new measuring machine software from ZOLLER that brings together form and function. With overview menus, concise buttons and a customizable user interface, the »pilot 4.0« helps you carry out every measurement efficiently. The software »metis« is the specialist for analyzing tools. It prepares measured values and image data comprehensively so you can make sound determinations about quality.

Customer-specific menu

Selection of measuring functions

Current position / Information on axes

Help / Information

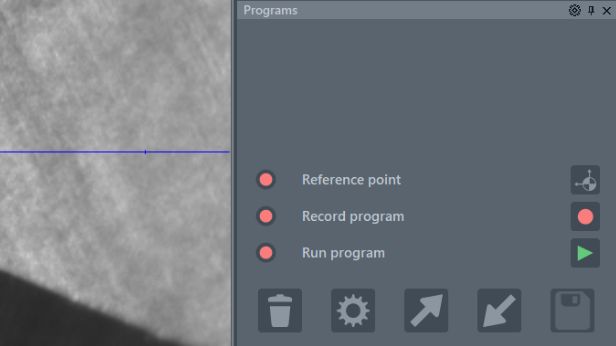

Automatic macro program sequence

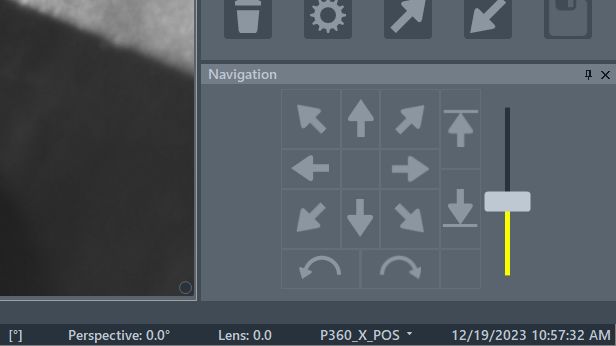

Camera and tool navigation