Your check for grinding wheels

With the »smileCheck«, you can check grinding wheels, as well as tools. The intuitive software guarantees the success of your inspection. In the 410 measuring program, for example, you will find grinding wheel types named according to the FEPA standard. Put together your grinding wheel pack with just a few mouse clicks or use the ZOLLER »elephant« program. This software independently detects grinding wheels and suggests the right measuring program for you.

Your check for grinding wheels

With the »smileCheck«, you can check grinding wheels, as well as tools. The intuitive software guarantees the success of your inspection. In the 410 measuring program, for example, you will find grinding wheel types named according to the FEPA standard. Put together your grinding wheel pack with just a few mouse clicks or use the ZOLLER »elephant« program. This software independently detects grinding wheels and suggests the right measuring program for you.

Leave no doubts

A high-quality camera and advanced image processing show the details of your tools and grinding wheels in impressive quality on the high-definition 24“ TFT color monitor. These images and measurement data show you how to grind or regrind a tool — or whether you should reject it.

Leave no doubts

A high-quality camera and advanced image processing show the details of your tools and grinding wheels in impressive quality on the high-definition 24“ TFT color monitor. These images and measurement data show you how to grind or regrind a tool — or whether you should reject it.

The right fit for your production

The »smileCheck« offers simple operation, high precision, reliability and connectivity to other machines — just as modern manufacturing demands. The integrated hardware and software insert seamlessly into your production, allowing you to check the quality of your tools efficiently and precisely.

The right fit for your production

The »smileCheck« offers simple operation, high precision, reliability and connectivity to other machines — just as modern manufacturing demands. The integrated hardware and software insert seamlessly into your production, allowing you to check the quality of your tools efficiently and precisely.

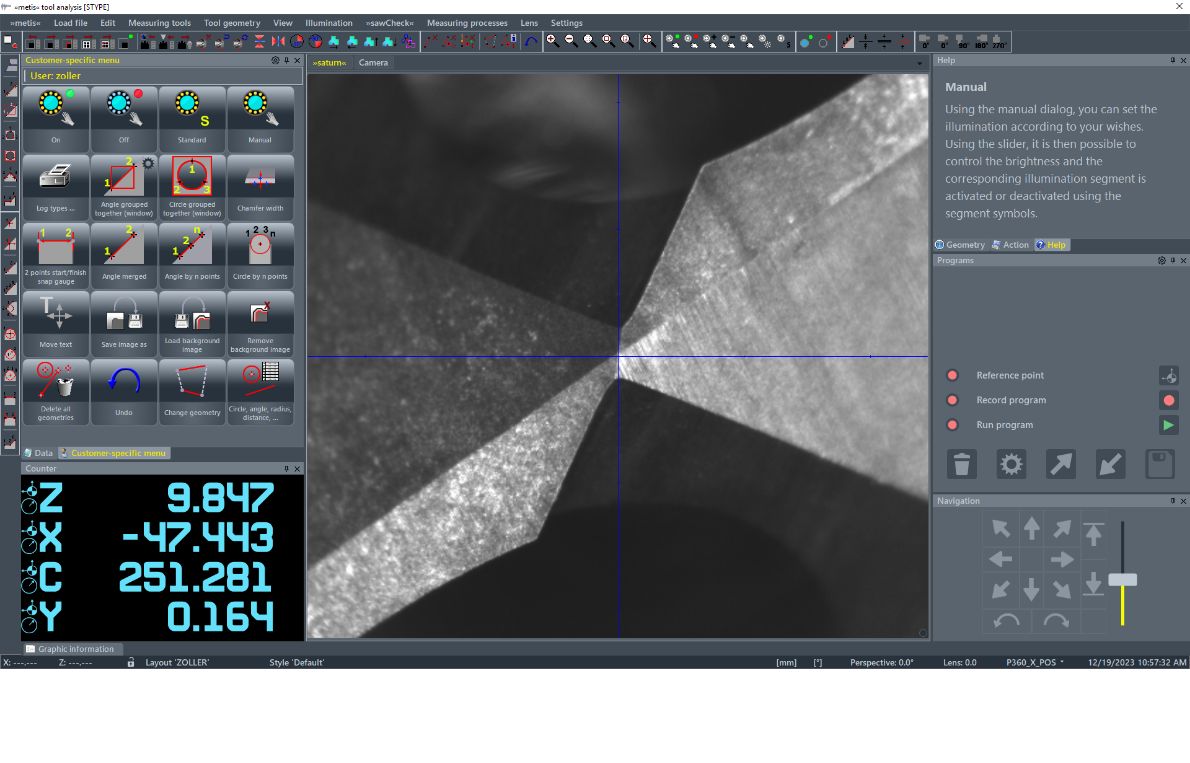

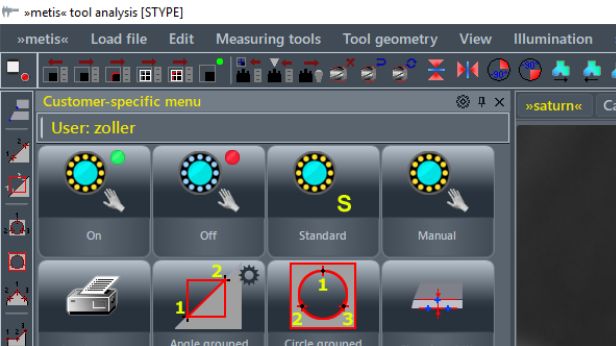

Software: »pilot 4.0« and »metis«

The »pilot 4.0« is the new measuring machine software from ZOLLER that brings together form and function. With overview menus, concise buttons and a customizable user interface, the »pilot 4.0« helps you carry out every measurement efficiently. The software »metis« is the specialist for analyzing tools. It prepares measured values and image data comprehensively so you can make sound determinations about quality.

Customer-specific menu

Selection of measuring functions

Current position / Information on axes

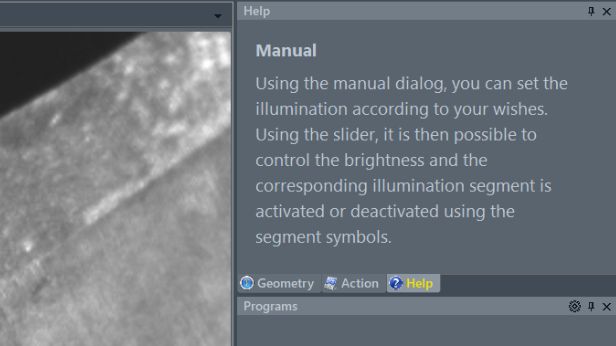

Help / Information

Automatic macro program sequence

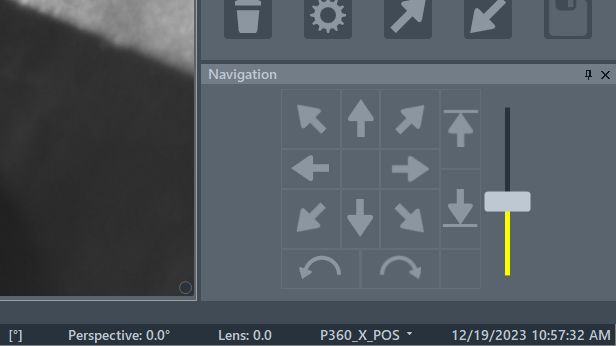

Camera and tool navigation