Features »toolBalancer«

»toolBalancer« Operating Software available in 25 languages

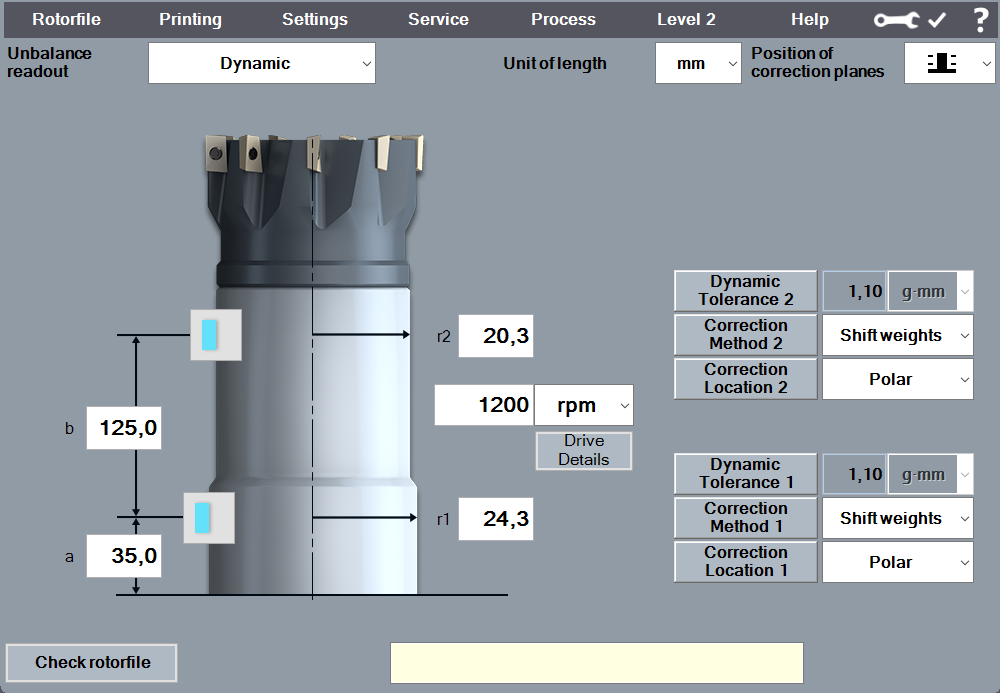

Intuitive software with graphical user interface for fast and simple balancing in 1 or 2 planes, including comprehensive standard functions.

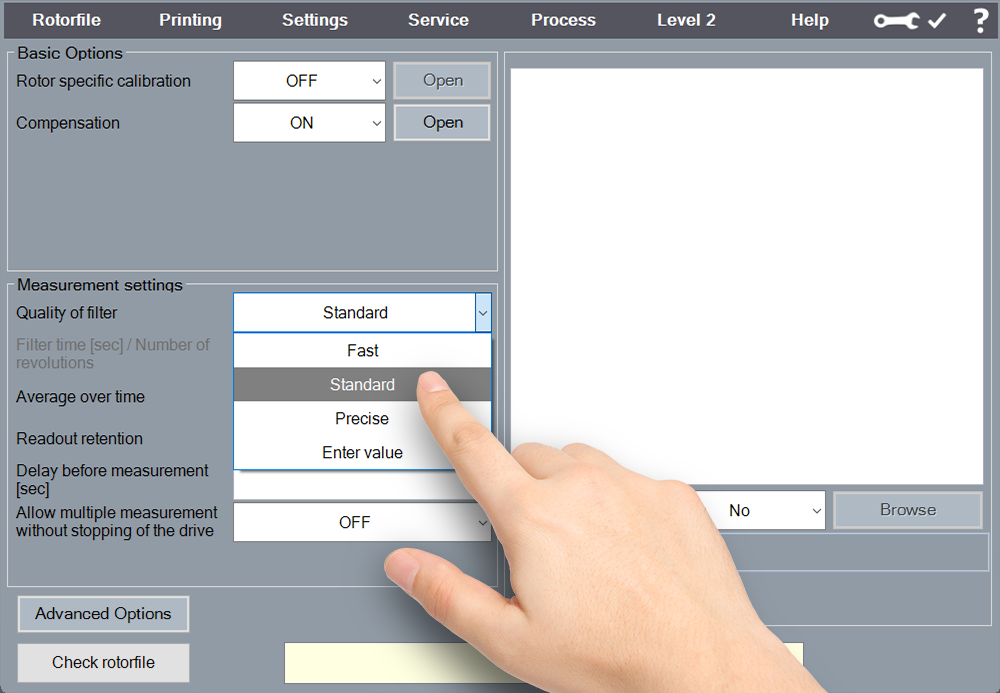

Touchscreen

Convenient software operation using the touchscreen.

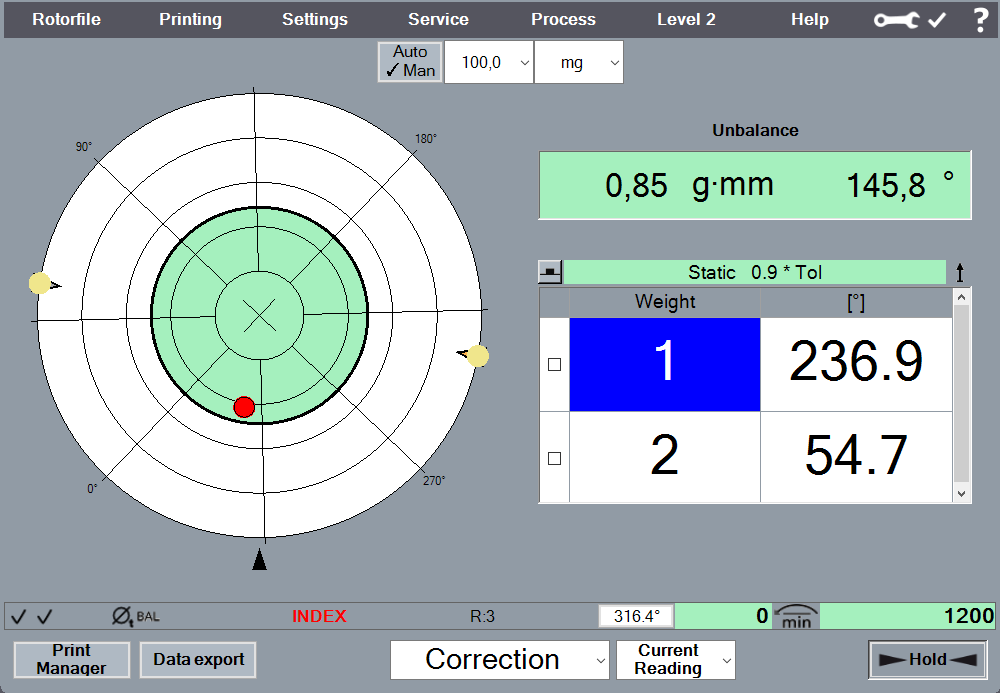

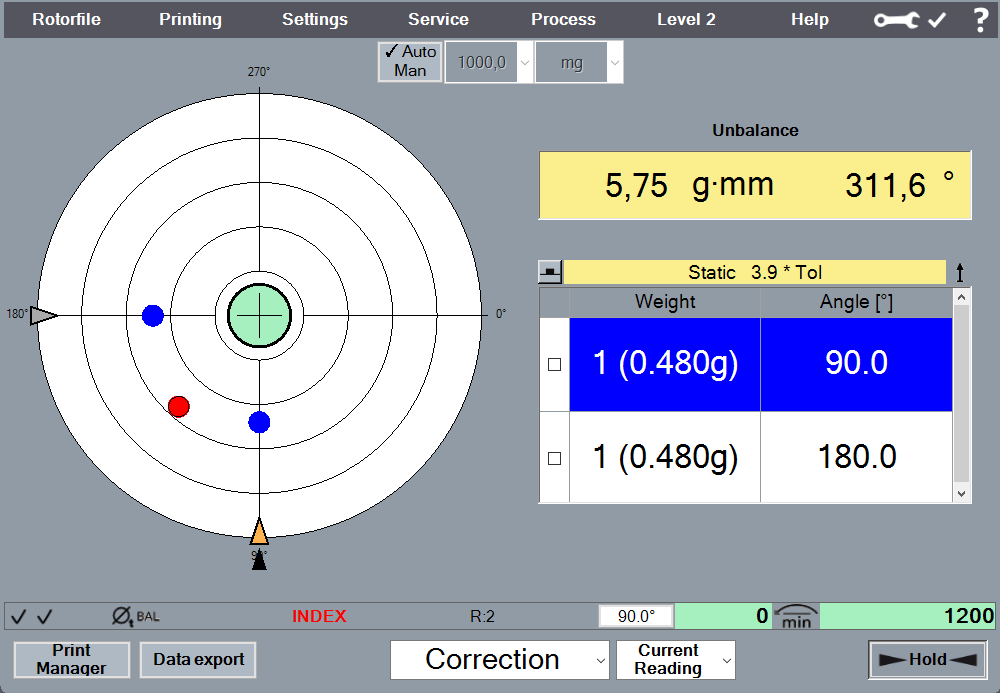

Visual insertion aid

Angular position of the spindle shown on the monitor.

Balance compensation

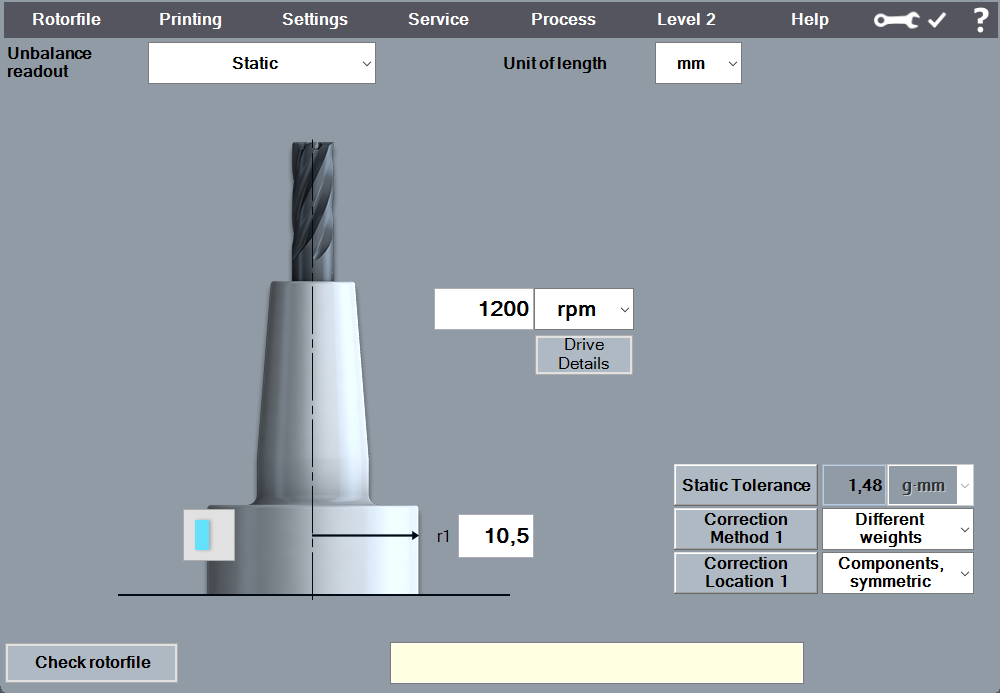

“Various weights” balancing correction

Correction of the imbalance by attaching or removing weights (e. g., balancing screws). Including ability to specify existing weight sets.

“Move weights” balancing correction

Correction of the imbalance by turning the balancing rings or slot nuts.

“Radial drilling” balancing correction

Correct imbalance through radial drilling. Automatic calculation of the number, angular position, and depth of the drill holes.

“Milling” balancing correction

Correction of the imbalance through radial, tangential, or axial milling.

“axial drilling” balancing correction

Correction of the imbalance by axial drilling. Automatic calculation of the number, angular position, and depth of the drill holes.

Laser marking

Displays imbalance and corrective position on the tool holder using a laser beam.

Balancing in one plane

For measuring and compensating for imbalance in one plane (static).

Balancing in two planes

For measuring and compensating for imbalance in two planes (dynamic imbalance).

Result of data output

Label printer

Output the measurement results in 1 or 2 levels on the ZOLLER thermal label printer.

Protocol printing

Output the measurement report as a printout on a laser printer, or as a .pdf file. Including editing function.

Measurement data export

User administration including 3 user levels with assignment of individual access rights.