»zidCode 4.0«

Internet of Tools

IoT usually stands for Internet of Things. At ZOLLER, we like to think of it as the "Internet of Tools". With the IoT platform »zidCode 4.0« you can network your cutting tools with the processes in your production. Thanks to many output formats, »zidCode 4.0« is compatible with many control systems.

With »zidCode 4.0« you'll understand all the prerequisites to make tool data, such as tool life, available at every level of a production process in order to digitally record the entire life cycle of a tool.

»zidCode 4.0«

Internet of Tools

IoT usually stands for Internet of Things. At ZOLLER, we like to think of it as the "Internet of Tools". With the IoT platform »zidCode 4.0« you can network your cutting tools with the processes in your production. Thanks to many output formats, »zidCode 4.0« is compatible with many control systems.

With »zidCode 4.0« you'll understand all the prerequisites to make tool data, such as tool life, available at every level of a production process in order to digitally record the entire life cycle of a tool.

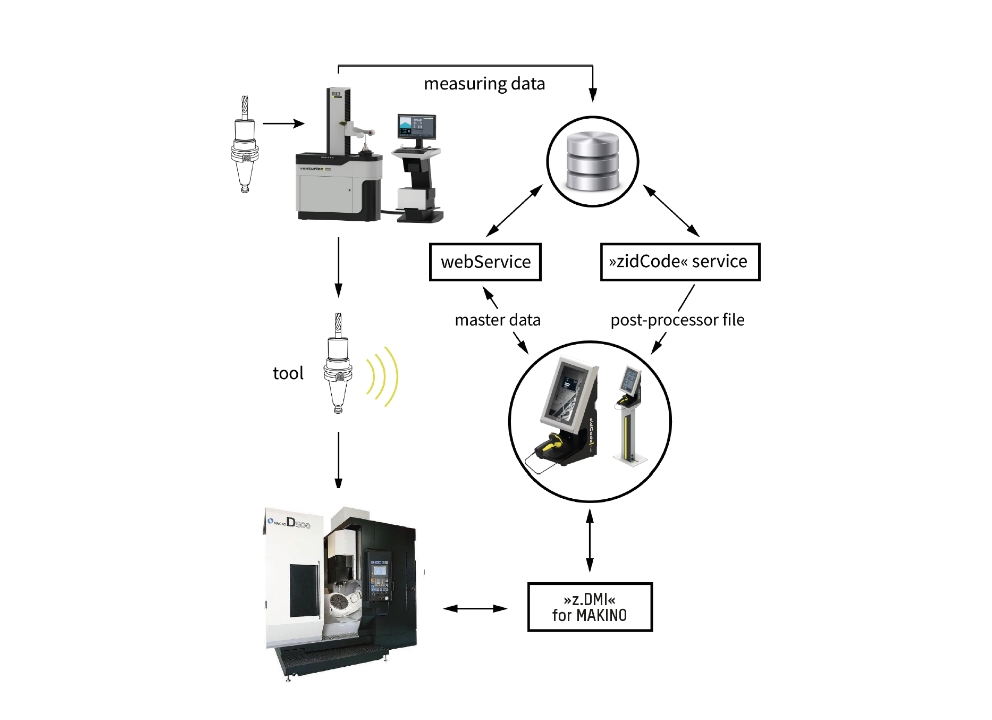

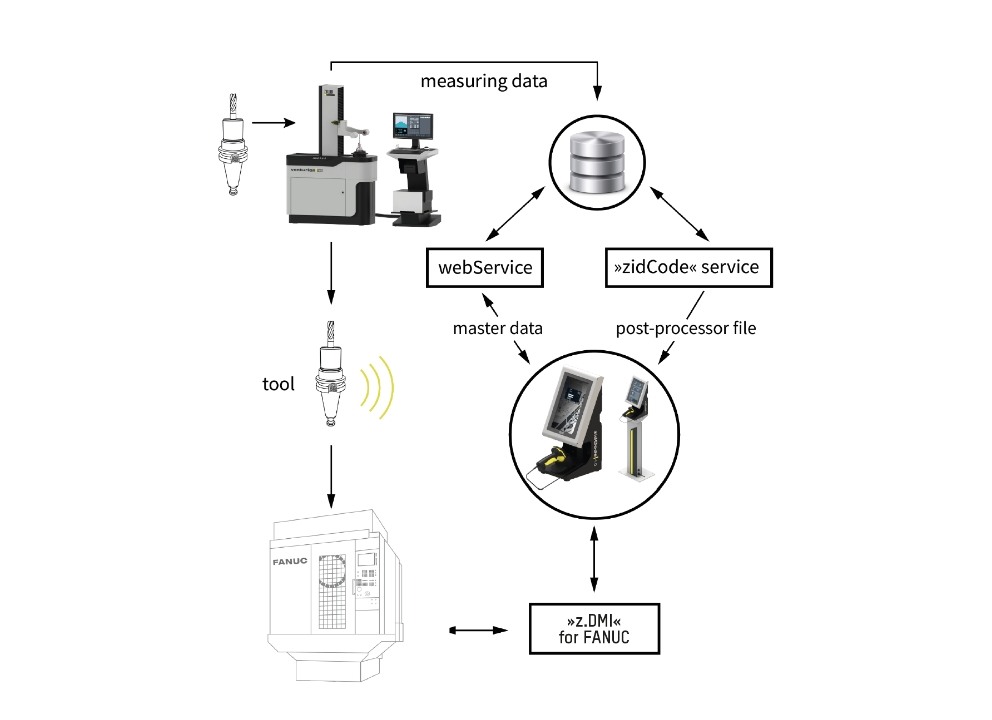

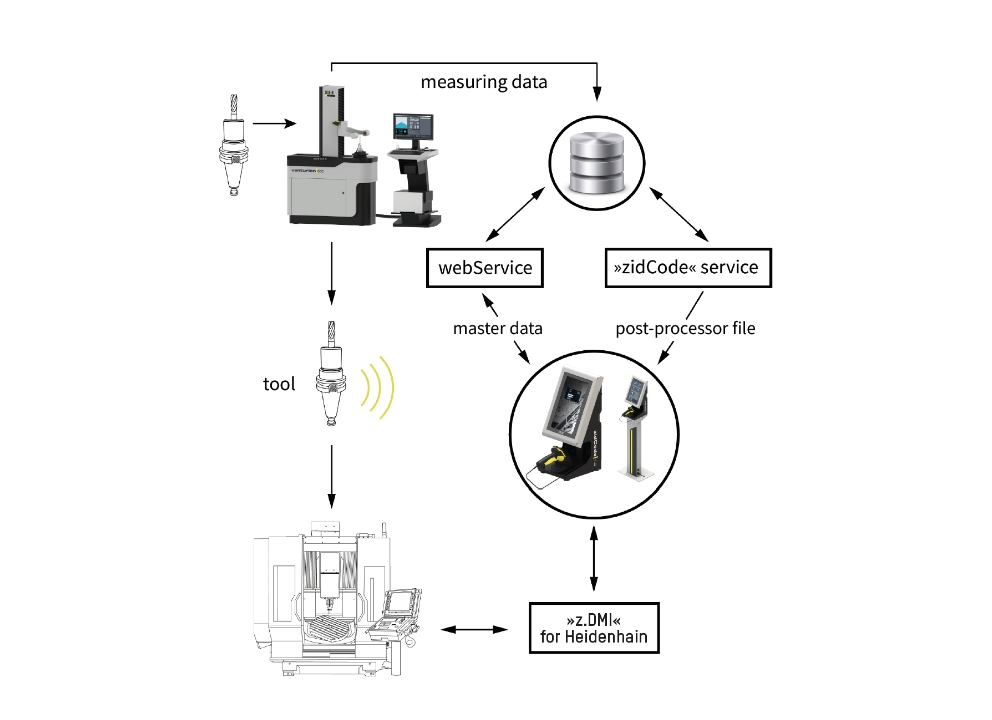

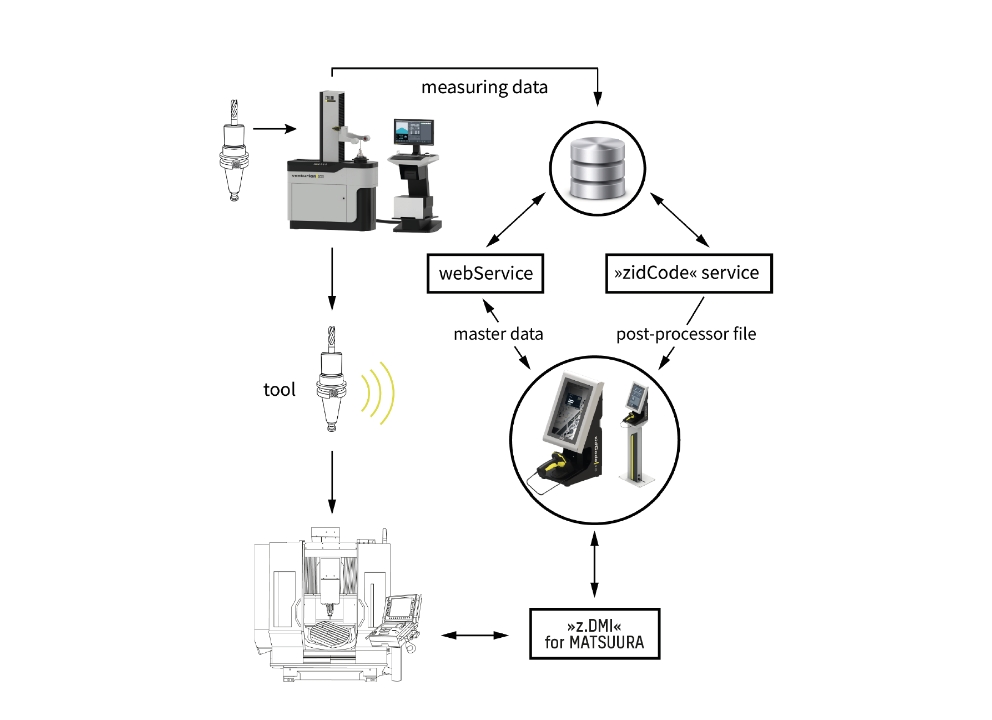

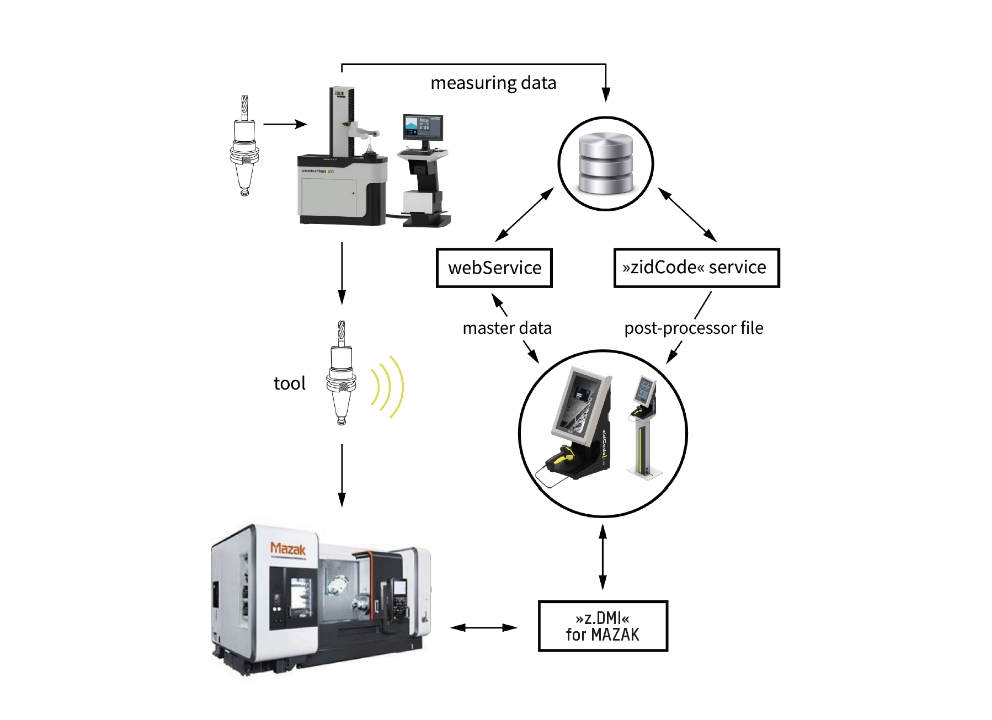

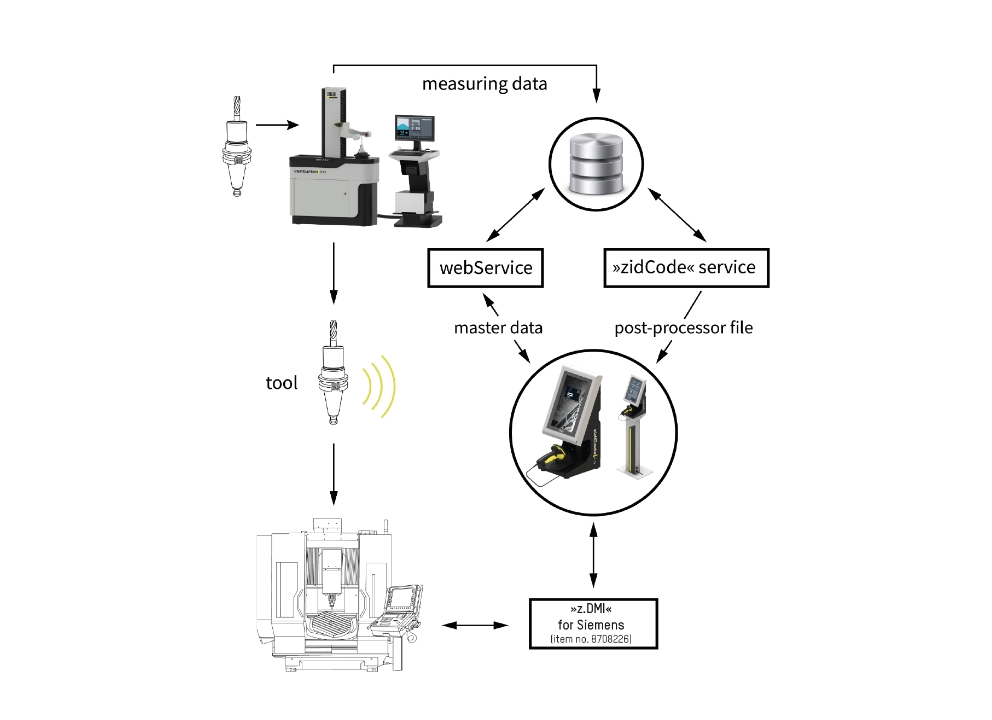

»z.DMI« Technology

For Efficient

Manufacturing

For Efficient

Manufacturing

ZOLLER »z.DMI« technology enables the direct transfer of tool data to the tool memory of the machine control and back to the z.One database.

- Easy operation due to automatized processes

- Process reliability thanks to data centralization

- Cost reduction by tool life management

Ready for Automation

Since the »zidCode 4.0« prepares your production processes for dynamic management of tool data, you'll have the foundation in place to incorporate even more automation!

The »zidCode 4.0« is the ideal basis for quickly integrating ZOLLER automation solutions into your production process later on. With ZOLLER, you'll always stay technologically up to date.

Ready for Automation

Since the »zidCode 4.0« prepares your production processes for dynamic management of tool data, you'll have the foundation in place to incorporate even more automation!

The »zidCode 4.0« is the ideal basis for quickly integrating ZOLLER automation solutions into your production process later on. With ZOLLER, you'll always stay technologically up to date.

Installation

Barcode reader 1D/2D per CNC machine

»zidCode 4.0« unit, including »zidCode 4.0« software package

USB stick (documentation, manual, training videos)

Cable kit (Ethernet, power cable)

Software module »zidCode 4.0« for installation on existing ZOLLER presetting and measuring machine

Windows Services for installation on a server or PC: ZOLLER WebService and »zidCodeService«