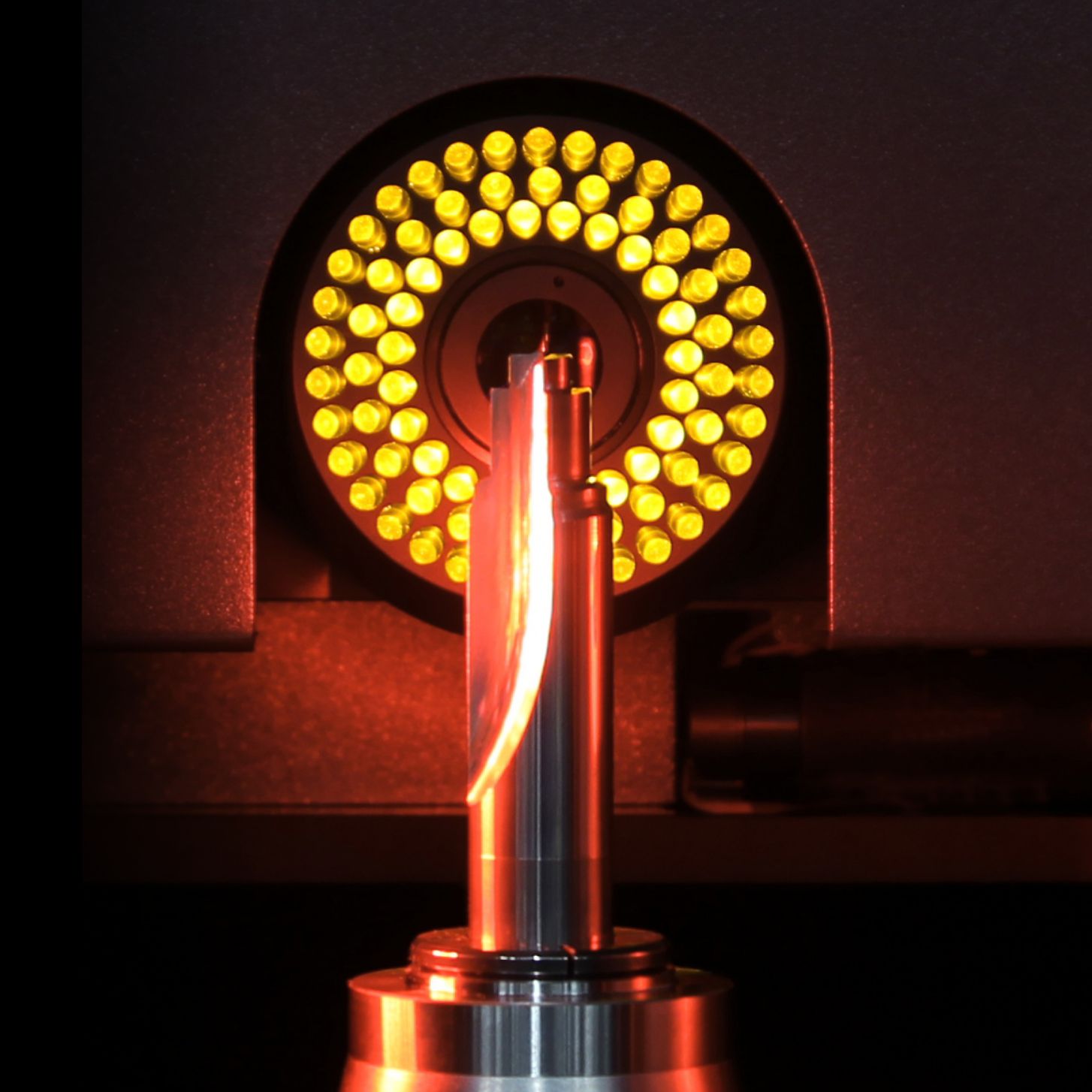

Don't touch!

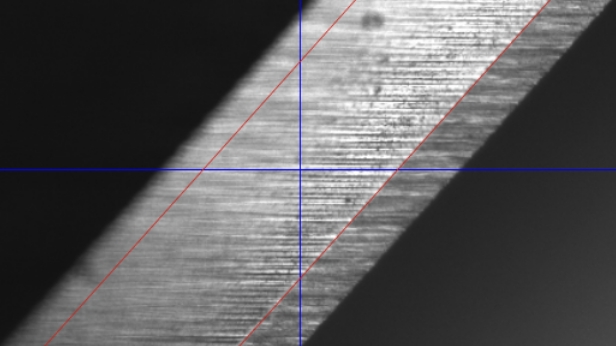

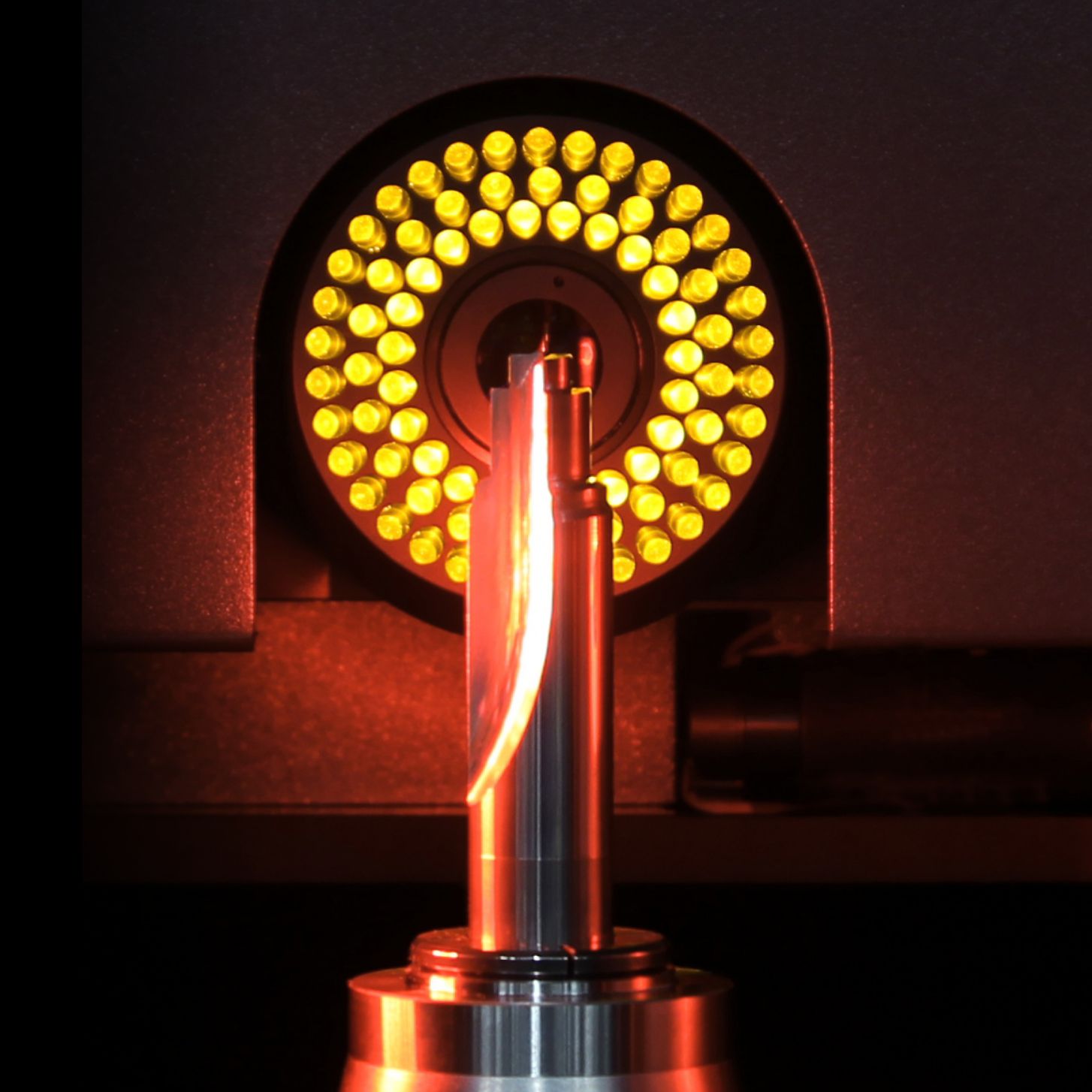

The »genius« measures without contact in incident and transmitted light. The LED ring lights provide ideal illumination of every tool for inspections on the face and the circumference, as well as in the chip space.

Rely on precise measurements with a high degree of accuracy and repeatability, regardless of the operator.

Don't touch!

The »genius« measures without contact in incident and transmitted light. The LED ring lights provide ideal illumination of every tool for inspections on the face and the circumference, as well as in the chip space.

Rely on precise measurements with a high degree of accuracy and repeatability, regardless of the operator.

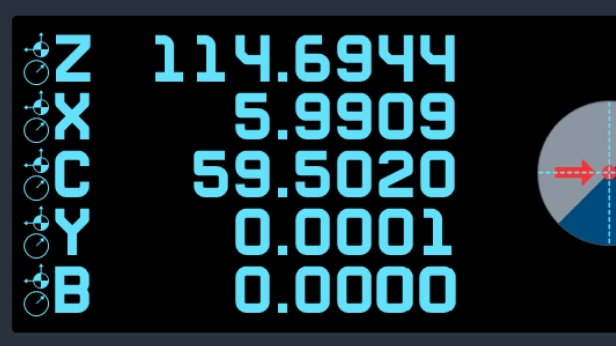

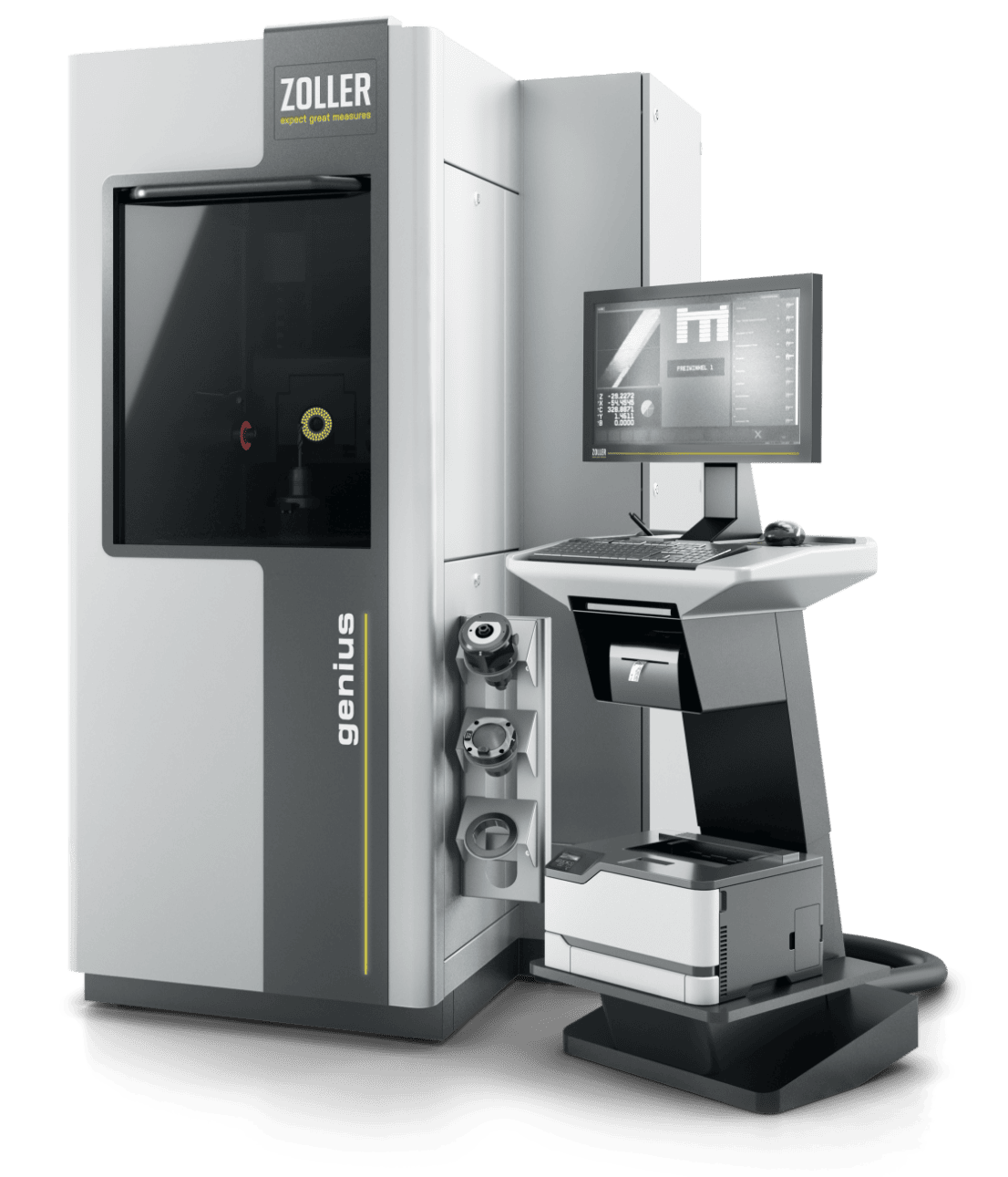

Automatically in position

Measuring with the »genius« eliminates the need to enter set values. The precise measuring technology and CNC equipment automatically carry out all the steps for correctly positioning a tool.

Automatically in position

Measuring with the »genius« eliminates the need to enter set values. The precise measuring technology and CNC equipment automatically carry out all the steps for correctly positioning a tool.

Solid and cool

A stable machine bed, optimum freedom from distortion and vibration-damping leveling elements guarantee the »genius« delivers exact measurement results even when set up close to production. The special ergonomics of the hardware and software simplify its operation.

To ensure that internal heat sources do not impair measuring, the control unit, power supply and electronics are housed in a separate control cabinet at the side of the measuring machine. Even with high requirements, the »genius« always stays cool.

Solid and cool

A stable machine bed, optimum freedom from distortion and vibration-damping leveling elements guarantee the »genius« delivers exact measurement results even when set up close to production. The special ergonomics of the hardware and software simplify its operation.

To ensure that internal heat sources do not impair measuring, the control unit, power supply and electronics are housed in a separate control cabinet at the side of the measuring machine. Even with high requirements, the »genius« always stays cool.

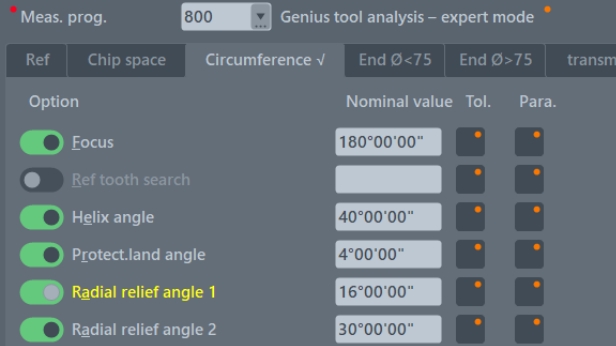

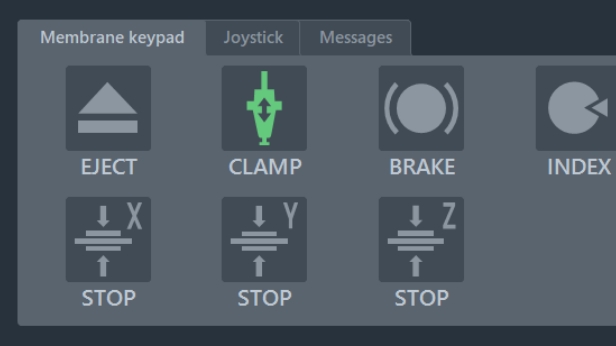

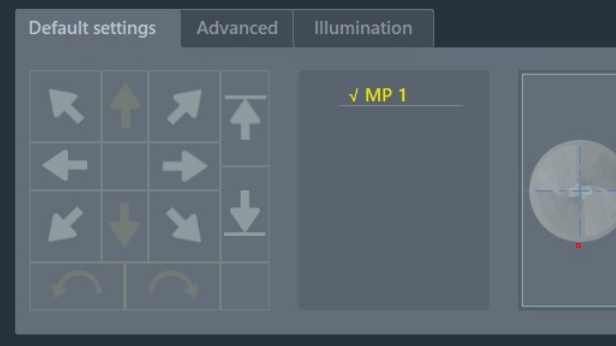

»pilot 4.0« makes measuring and testing particularly easy

ZOLLER's »pilot 4.0« image processing software is the most advanced and user-friendly software for operating a measuring machine such as the »genius«. The software offers a customizable interface, clear menus and large buttons.

Actual camera image

Selectable parameters

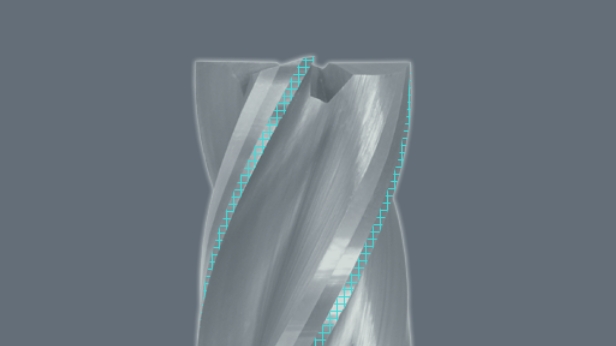

Photorealistic representation

2D measuring routine

Digital softkeys

Virtual joystick