Measuring changes everything

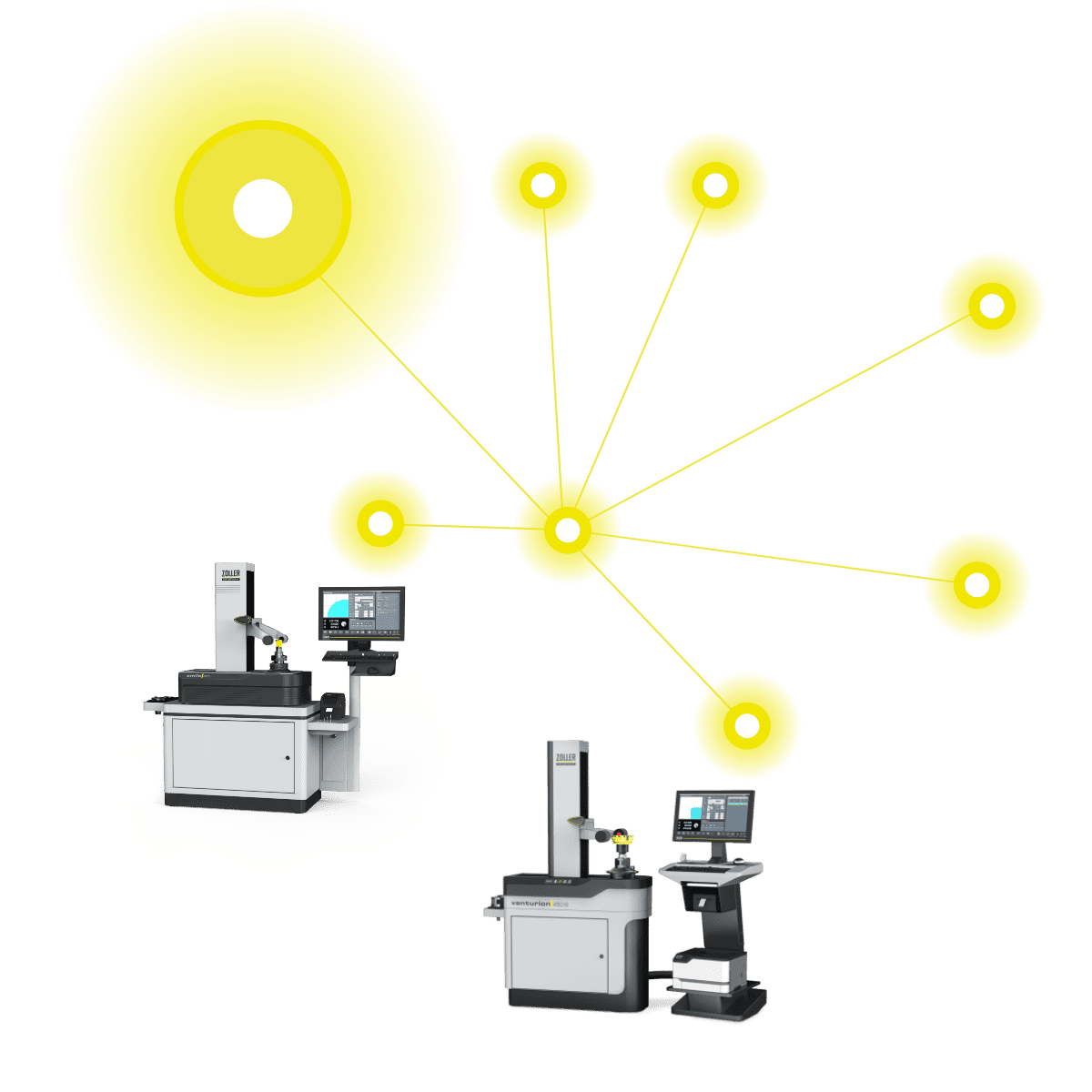

Maximize your production and tap into major savings with the »smile 420« and the »venturion 450« solutions.

Setting you up for success

When the competition is tough, you need every possible advantage to stay ahead.

Accurately measuring your tools with the »smile 420« or »venturion 450« gives you that extra edge.

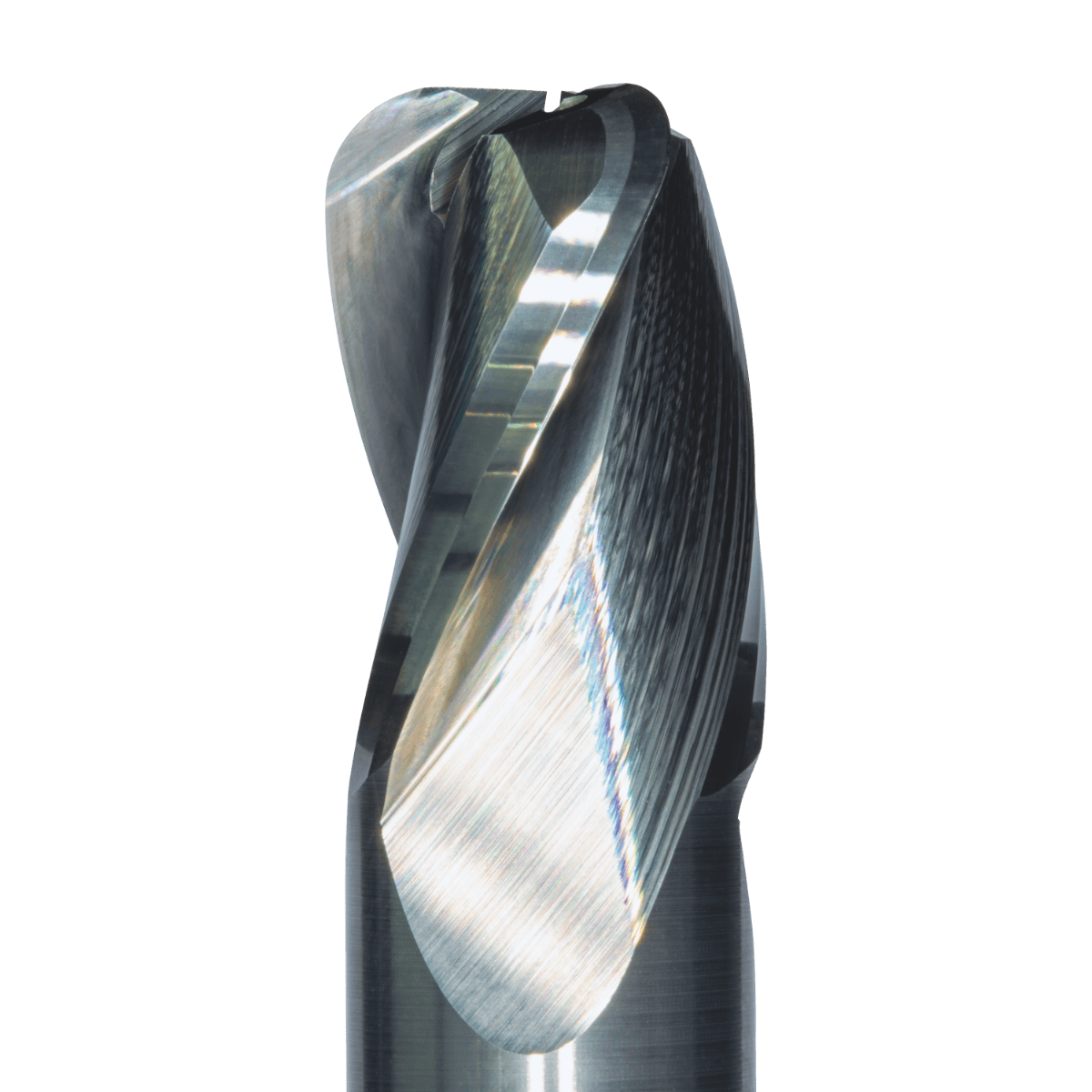

Extend the life of your tools, maximize the value of your CNC machines and produce a higher quality product.

Schedule 1:1 expert meeting

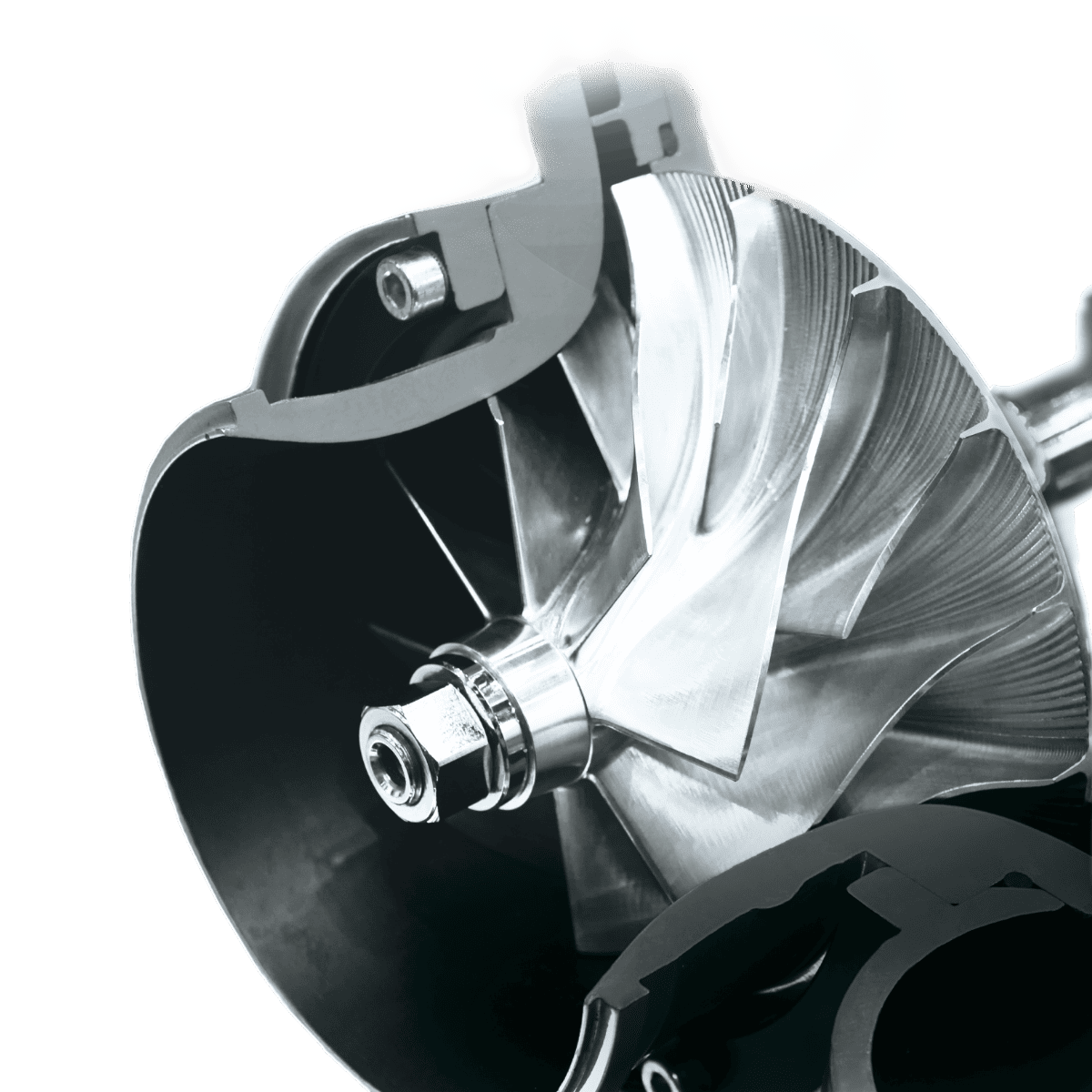

Extend tool life

Tool geometries and dimensions are translated into precise tool data. The CNC machine then uses the tool efficiently and with minimal wear.

Reduce setup times

Measurement on a presetting and measuring machine is faster and more precise than measurement in a CNC machine. Setup times are reduced because tools arrive at the machine ready to go.

Annual savings potential per CNC machine*

20000 USD

*Calculated for 20 tool changes with 3 minute changeover times, 200 working days per year, one shift per day and a $100 hourly machine rate