Ergonomics in the handle

The »eQ« (ergonomic and quick) one-hand control handle is all you need to adjust the entire appliance tower in the X-axis and Z-axis with just one hand. In addition, important functions can be assigned to the »eQ« release button. This makes operation even more convenient and ergonomic.

Ergonomics in the handle

The »eQ« (ergonomic and quick) one-hand control handle is all you need to adjust the entire appliance tower in the X-axis and Z-axis with just one hand. In addition, important functions can be assigned to the »eQ« release button. This makes operation even more convenient and ergonomic.

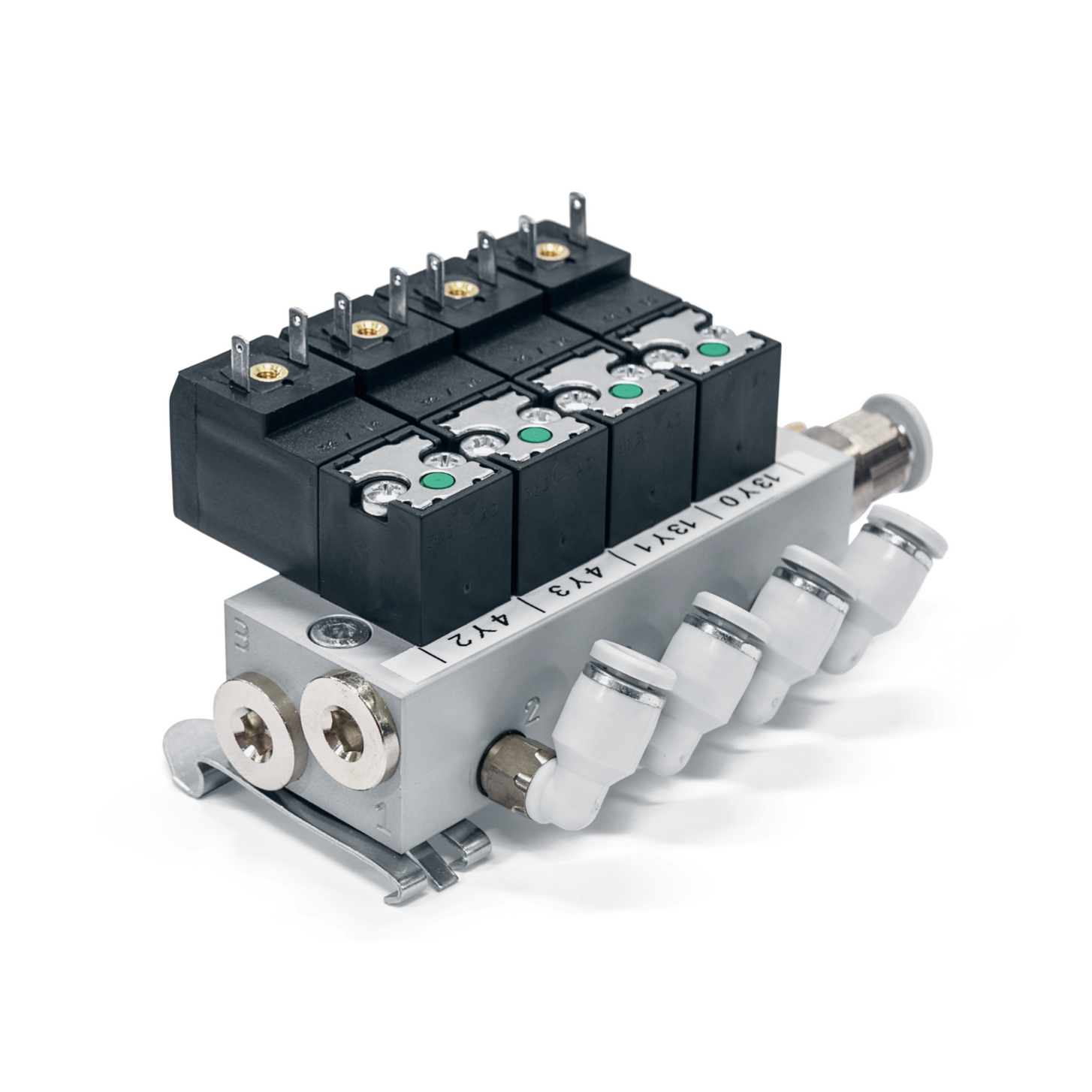

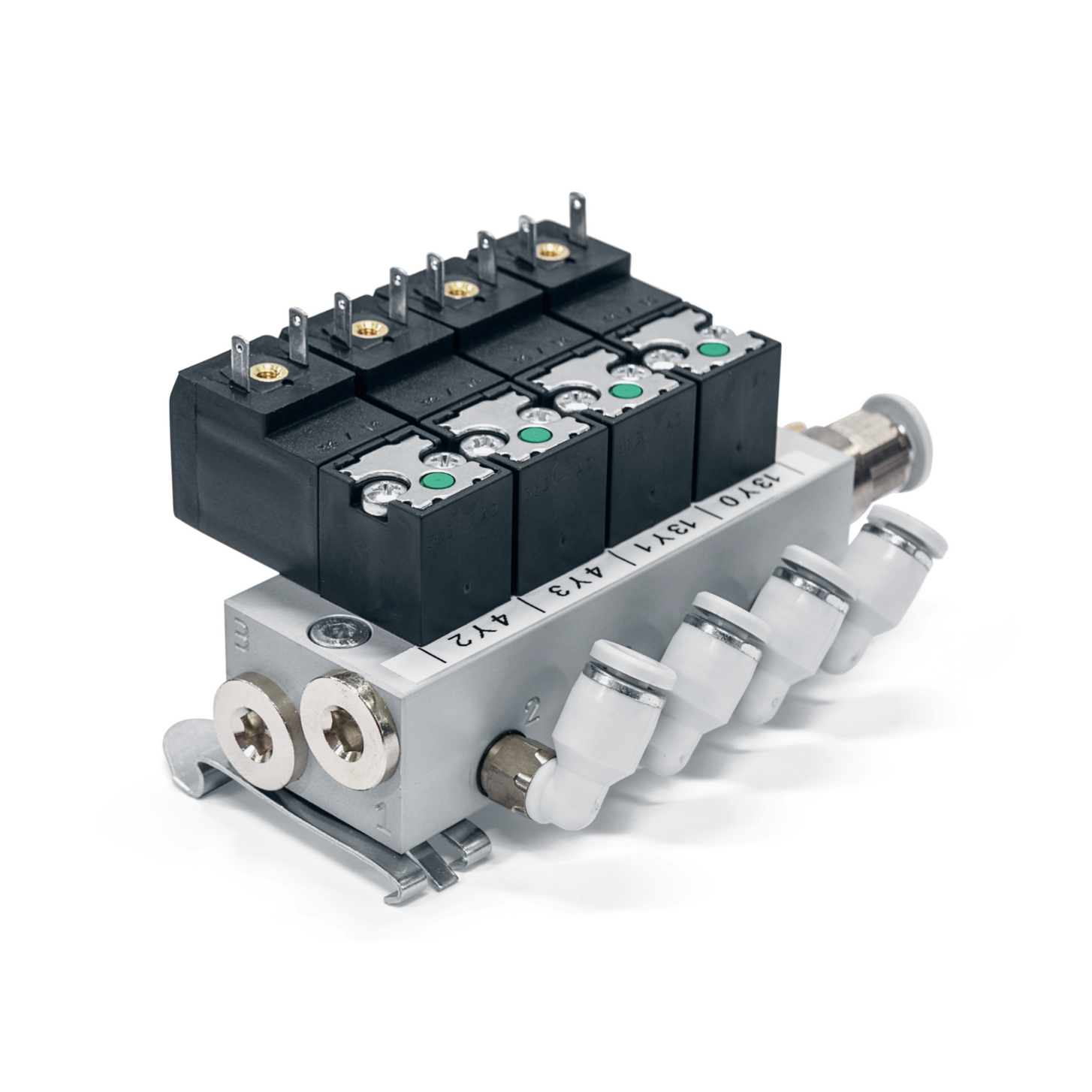

Prepared for high precision

The SK 50 spindle records adapters with SK50 holding. It delivers precise results with every measurement thanks to its special features. It has a concentricity of < 2 µm, a pneumatics spindle brake, 4 x 90° spindle indexing and integrated calibration balls.

Prepared for high precision

The SK 50 spindle records adapters with SK50 holding. It delivers precise results with every measurement thanks to its special features. It has a concentricity of < 2 µm, a pneumatics spindle brake, 4 x 90° spindle indexing and integrated calibration balls.

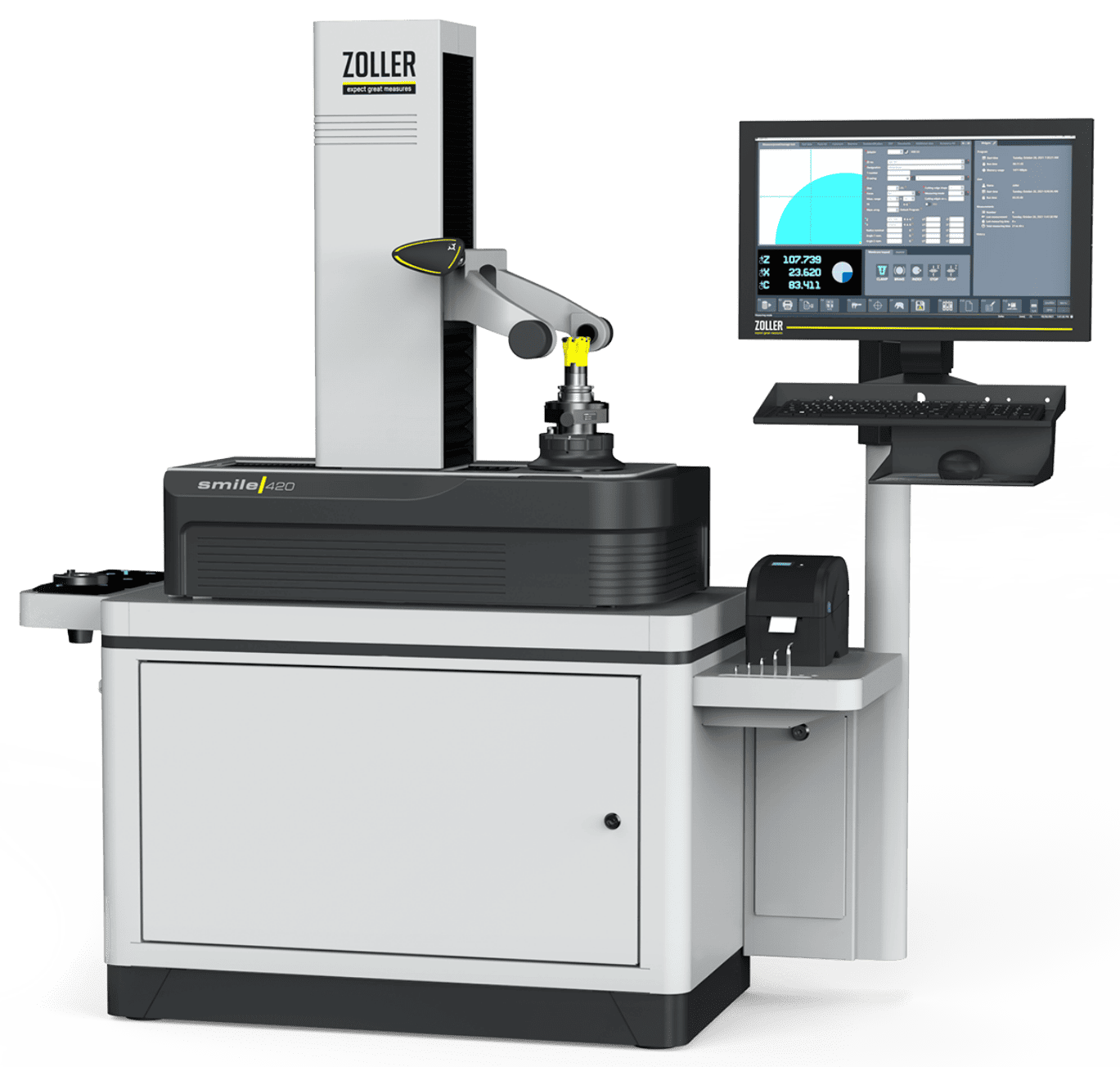

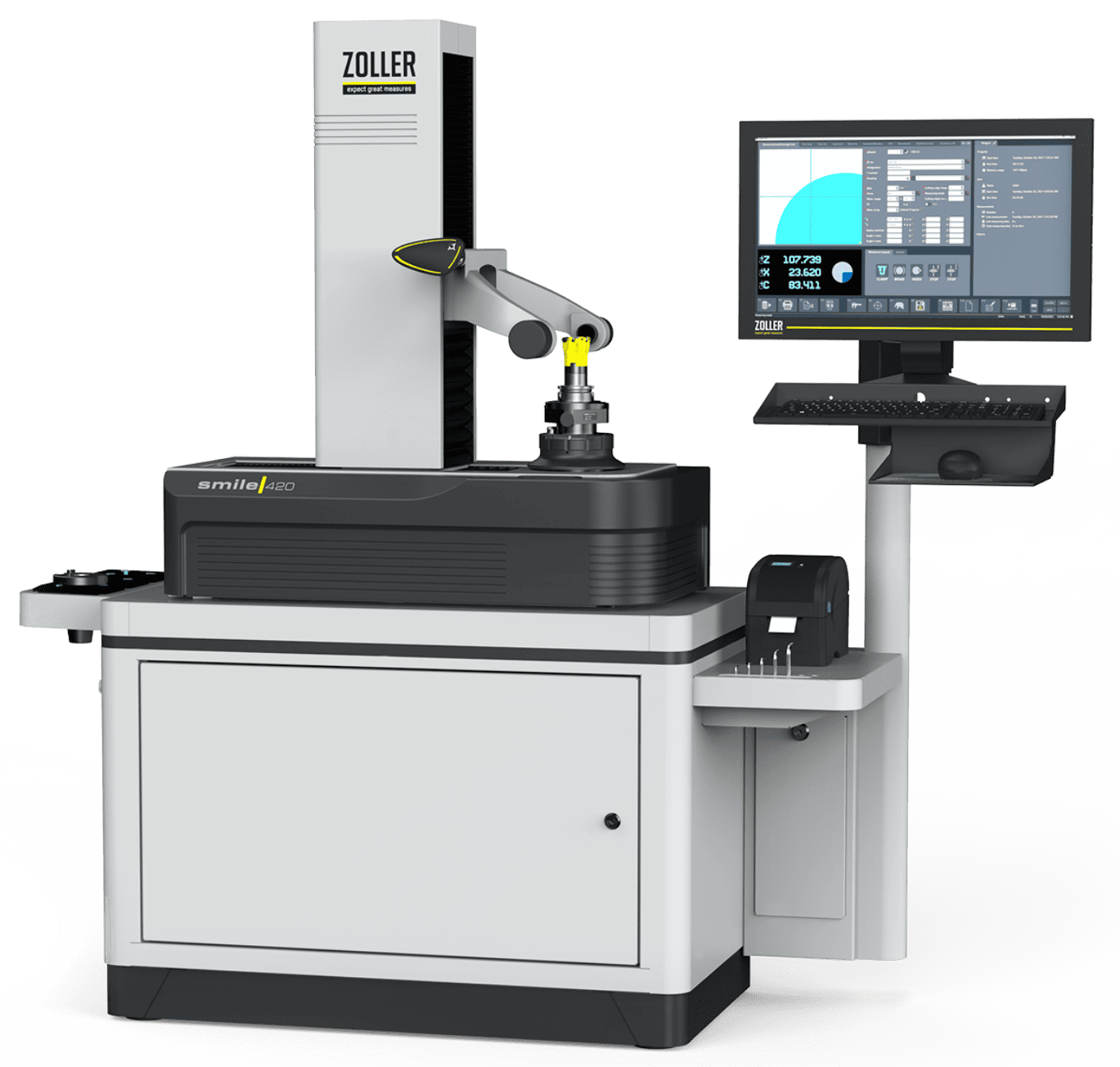

Built for production

Everything about the »smile 420« is designed for durability and continuous use. Whether it's a large-scale setup, a medium-sized operation or a small shop, this presetting and measuring machine keeps up with your production. It can even be situated right next to the CNC machine.

Built for production

Everything about the »smile 420« is designed for durability and continuous use. Whether it's a large-scale setup, a medium-sized operation or a small shop, this presetting and measuring machine keeps up with your production. It can even be situated right next to the CNC machine.

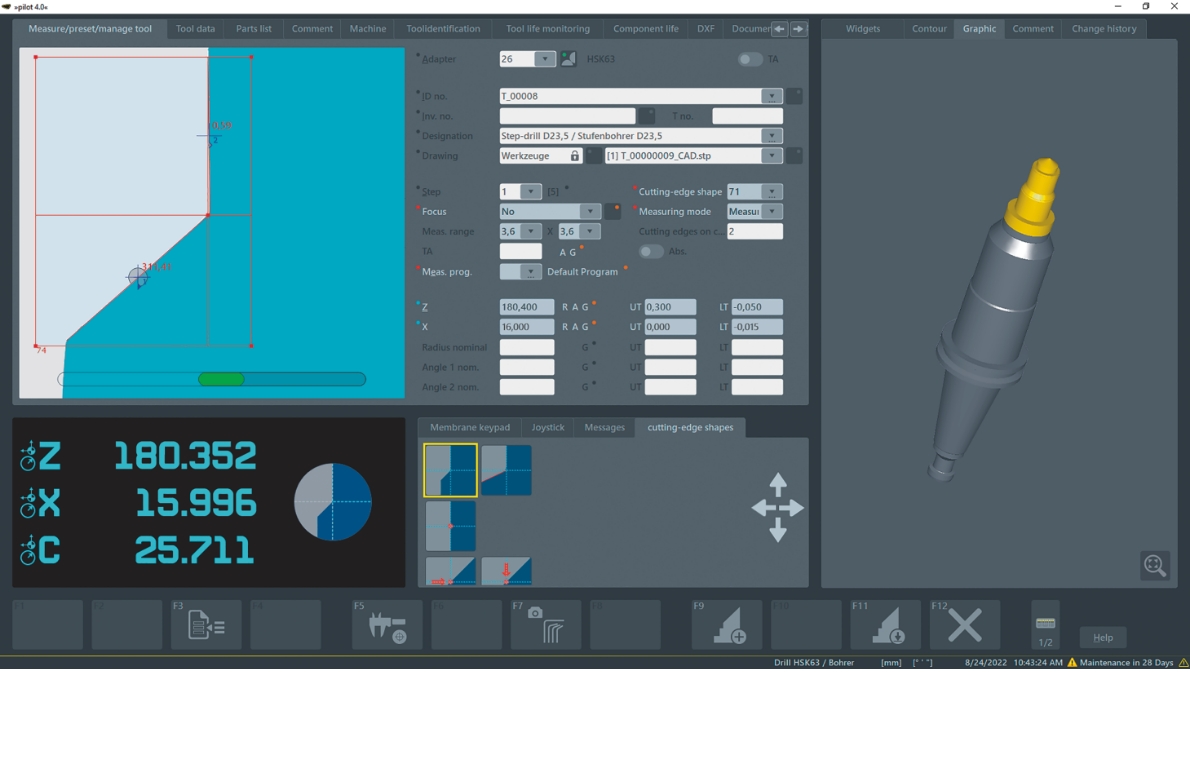

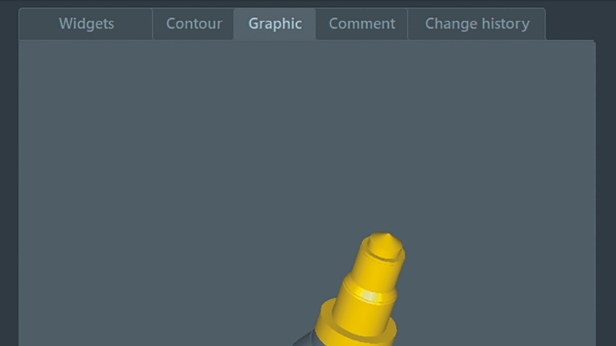

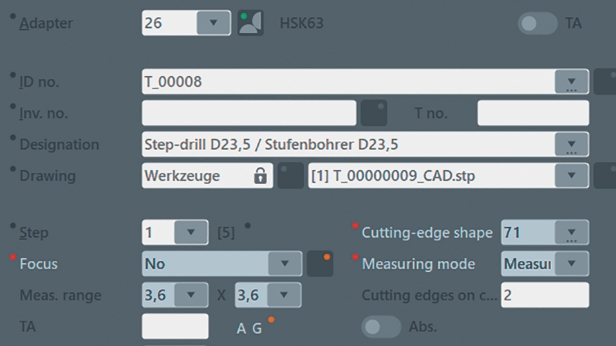

ZOLLER »pilot 4.0« software sets the standard

ZOLLER »pilot 4.0« is the user-friendly device software and image processing of your »smile 420« and »venturion 450«. With the intuitive graphic user guidance, you can quickly and reliably obtain precise measurement results and production-relevant tool data. Even complex measuring tasks can be completed immediately. There's a good reason »pilot 4.0« is recognized as the world standard for tool presetting, measuring and testing.

Tool-specific information

Adapter management

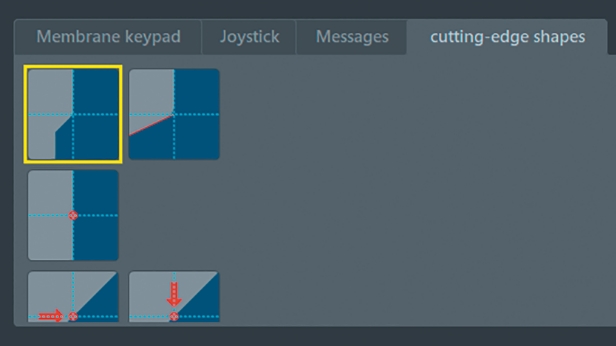

Cutting-edge shapes

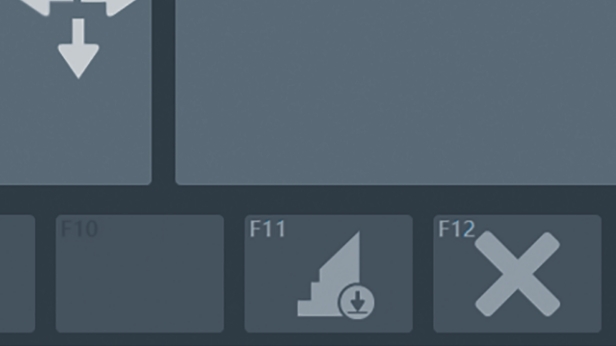

Function buttons

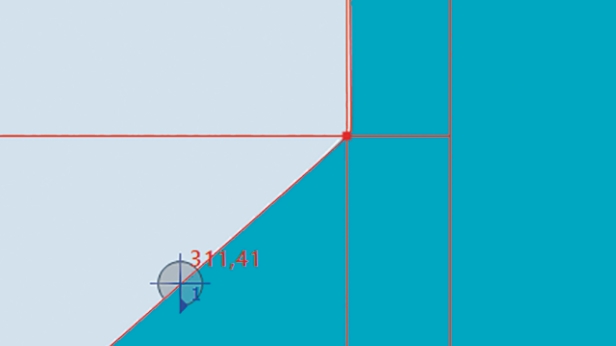

Current camera image

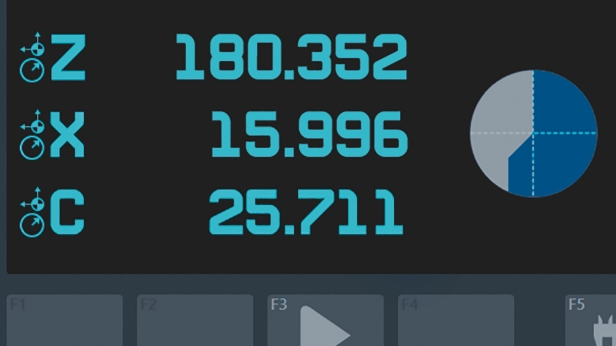

Current position information