Tooth By Tooth in the Focus of the Probe

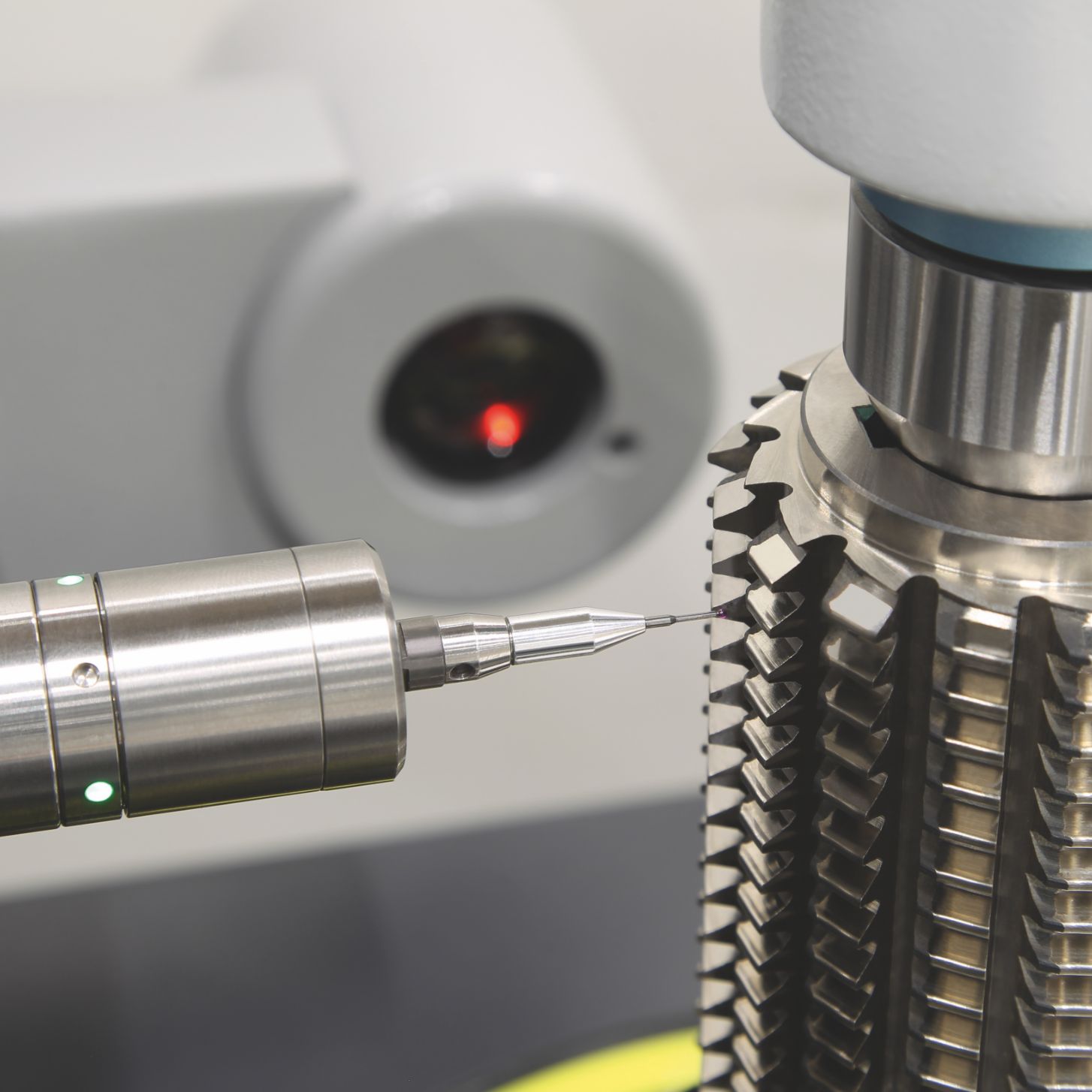

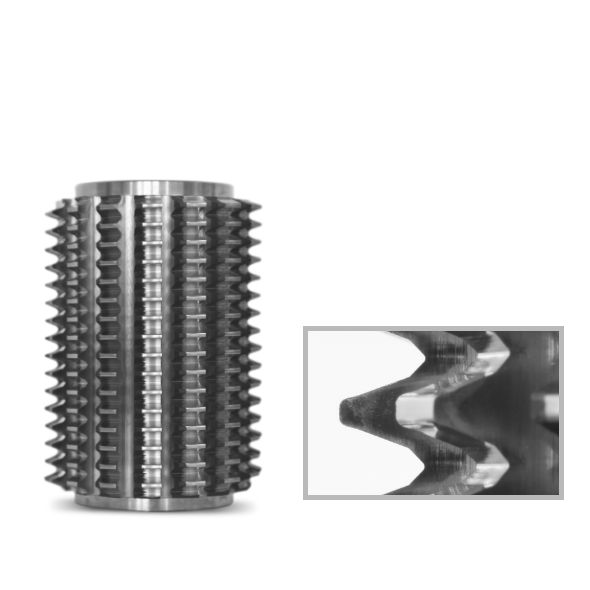

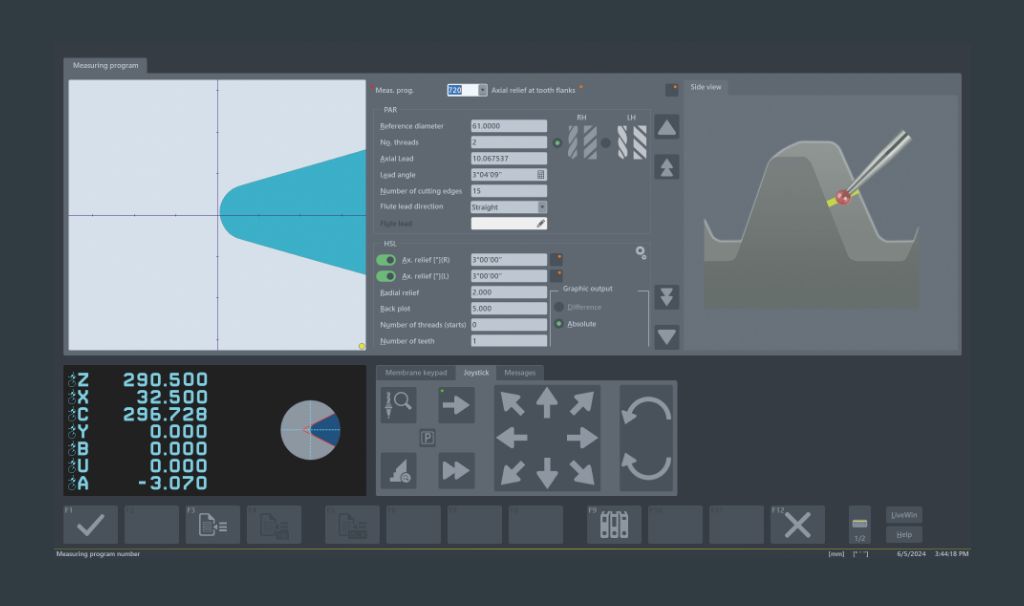

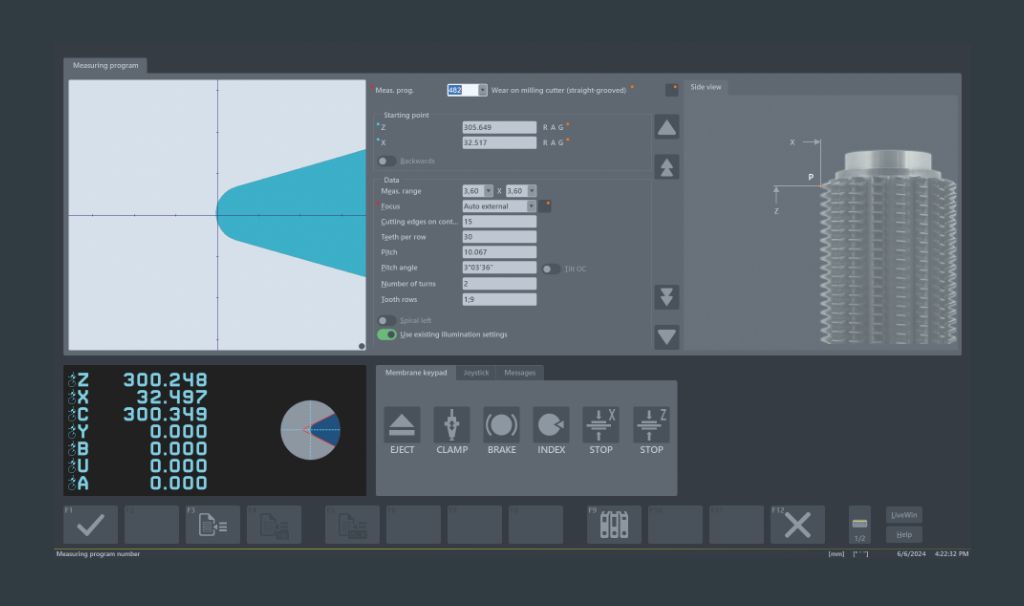

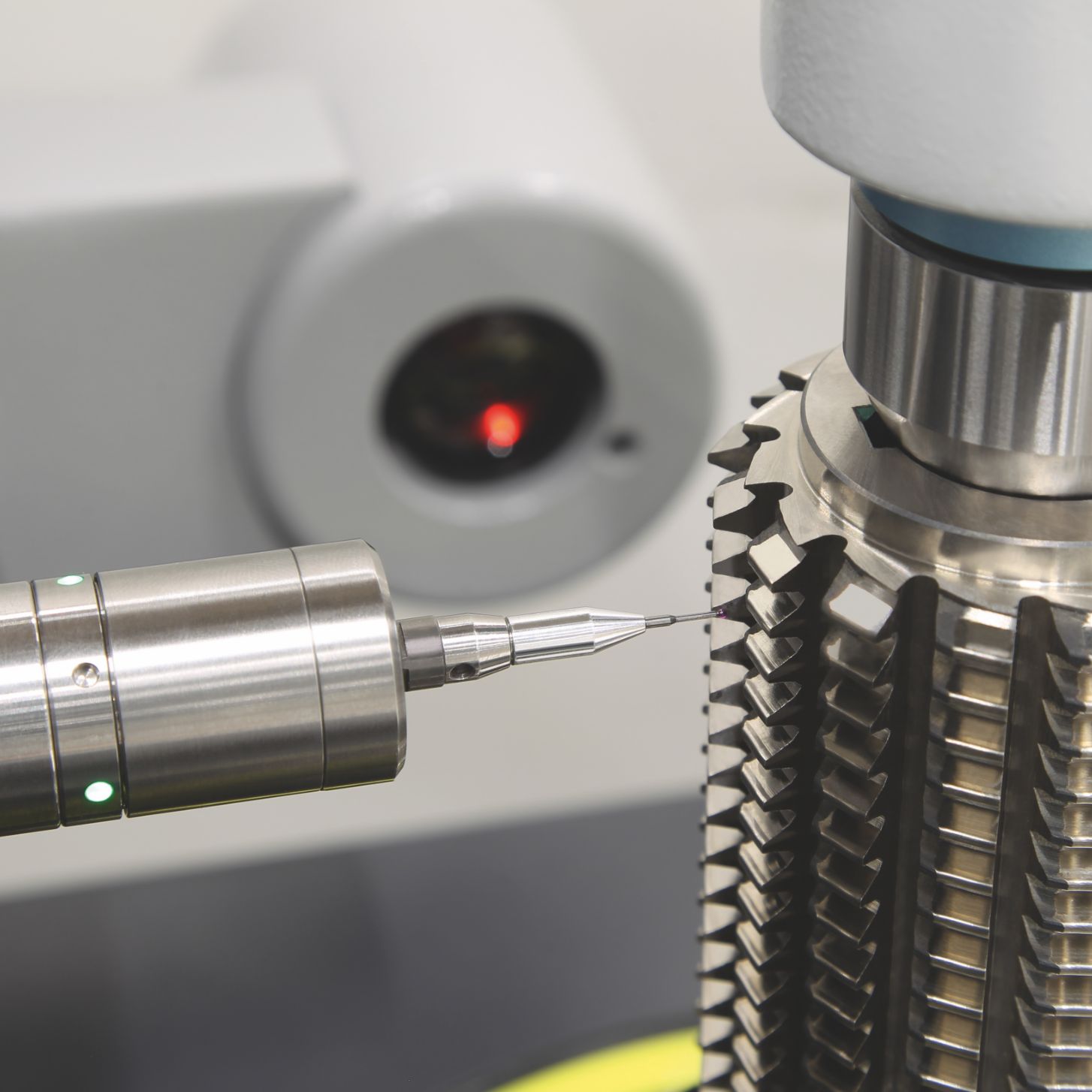

The electronic measuring probe supplements the ZOLLER sensor system for measurements on undercut surfaces to determine form and position deviation of the rake faces, pitch of the flutes and flute direction. The optics carrier of the »hobCheck« offers unique possibilities for the complete measurement of straight-fluted and helical gear cutting tools thanks to its integrated CNC Y-axis.

Tooth By Tooth in the Focus of the Probe

The electronic measuring probe supplements the ZOLLER sensor system for measurements on undercut surfaces to determine form and position deviation of the rake faces, pitch of the flutes and flute direction. The optics carrier of the »hobCheck« offers unique possibilities for the complete measurement of straight-fluted and helical gear cutting tools thanks to its integrated CNC Y-axis.