We Stand for Smart Progress

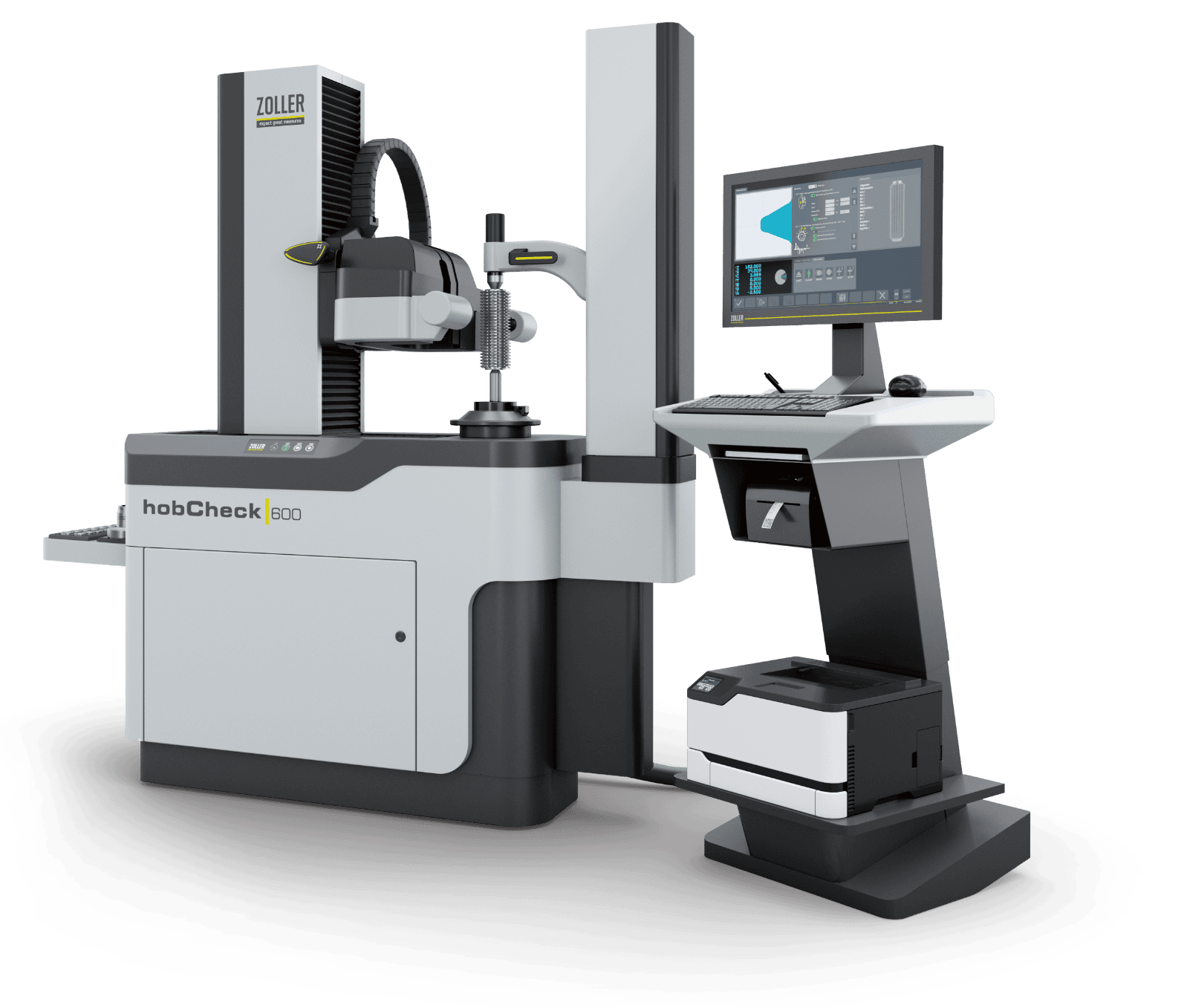

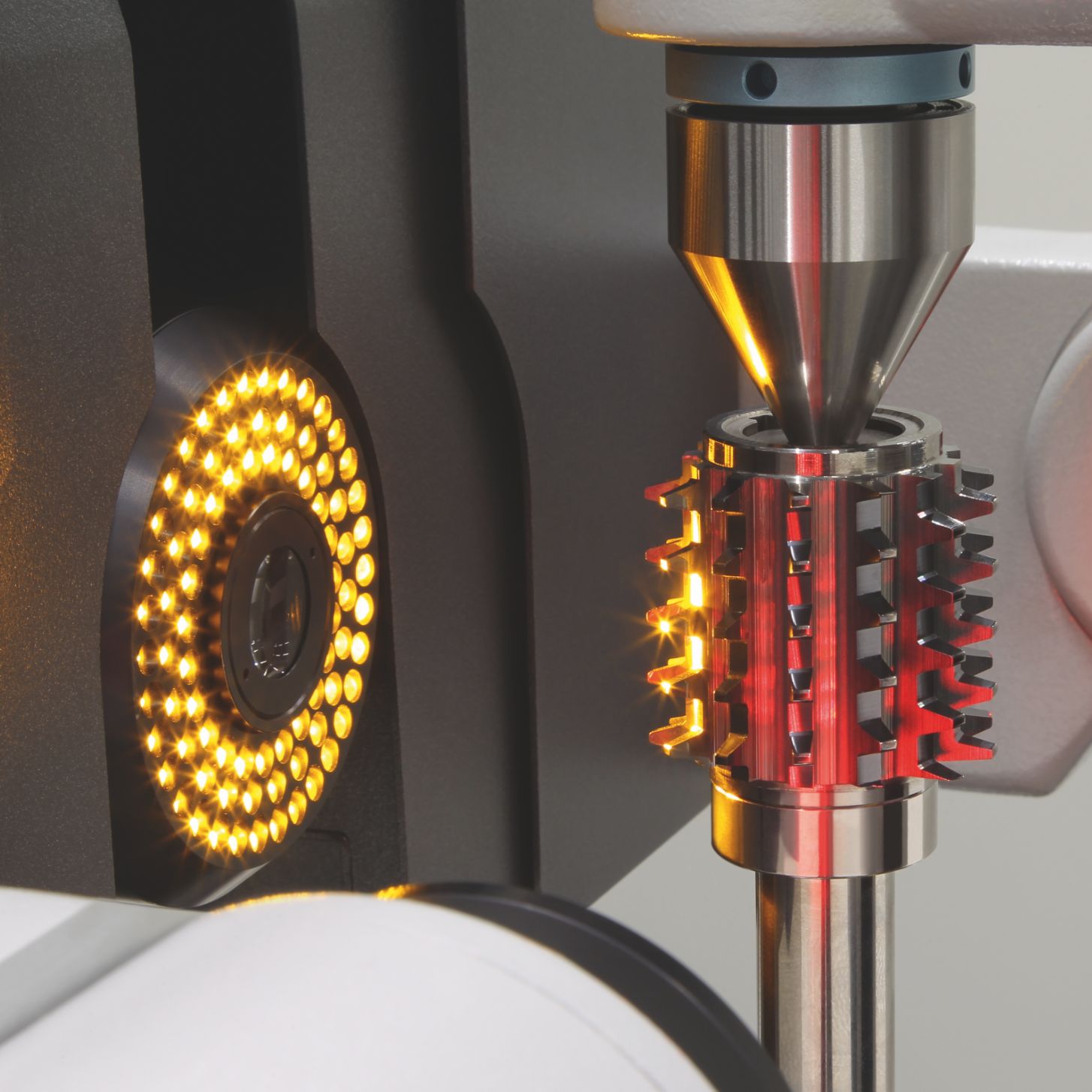

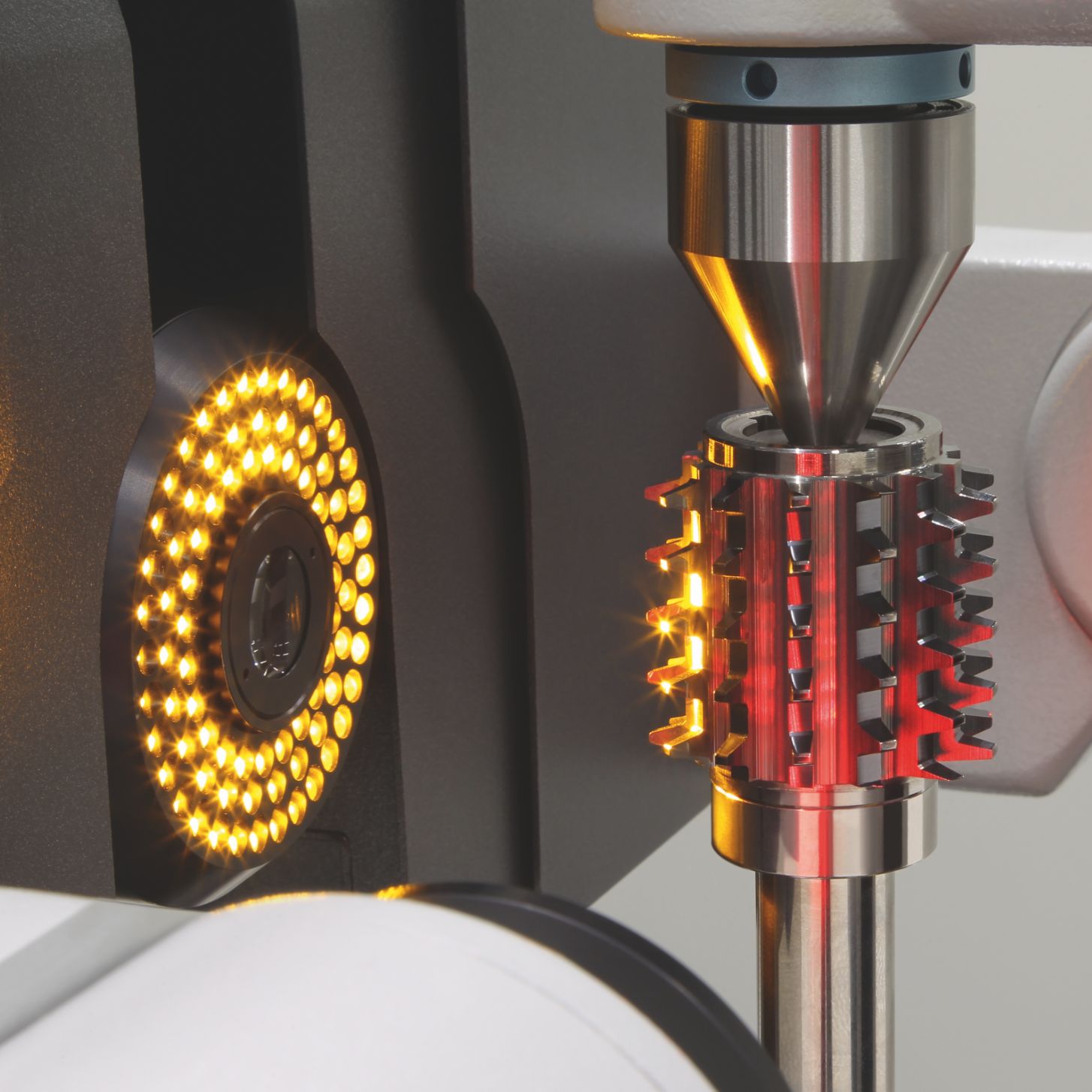

The »hobCheck« universal measuring machine from ZOLLER opens up unprecedented possibilities for the fully automatic and complete measurement of gear cutting tools, threading tools and cutting tools of all kinds.

The swiveling »orthoScan« optics carrier guarantees distortion-free measurement of the tooth contour for tools with a pitch, allowing you to achieve highly precise measurement results.

We Stand for Smart Progress

The »hobCheck« universal measuring machine from ZOLLER opens up unprecedented possibilities for the fully automatic and complete measurement of gear cutting tools, threading tools and cutting tools of all kinds.

The swiveling »orthoScan« optics carrier guarantees distortion-free measurement of the tooth contour for tools with a pitch, allowing you to achieve highly precise measurement results.

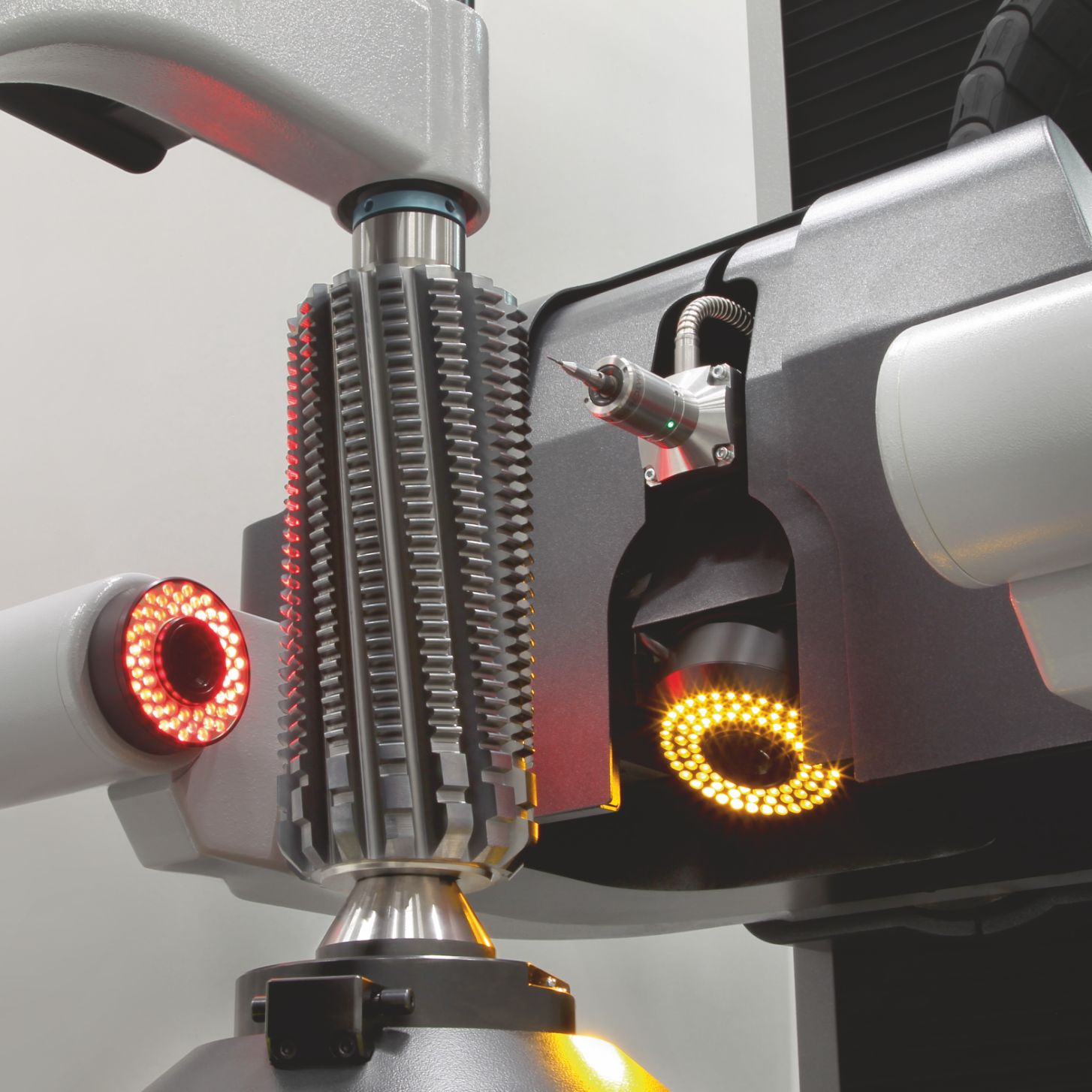

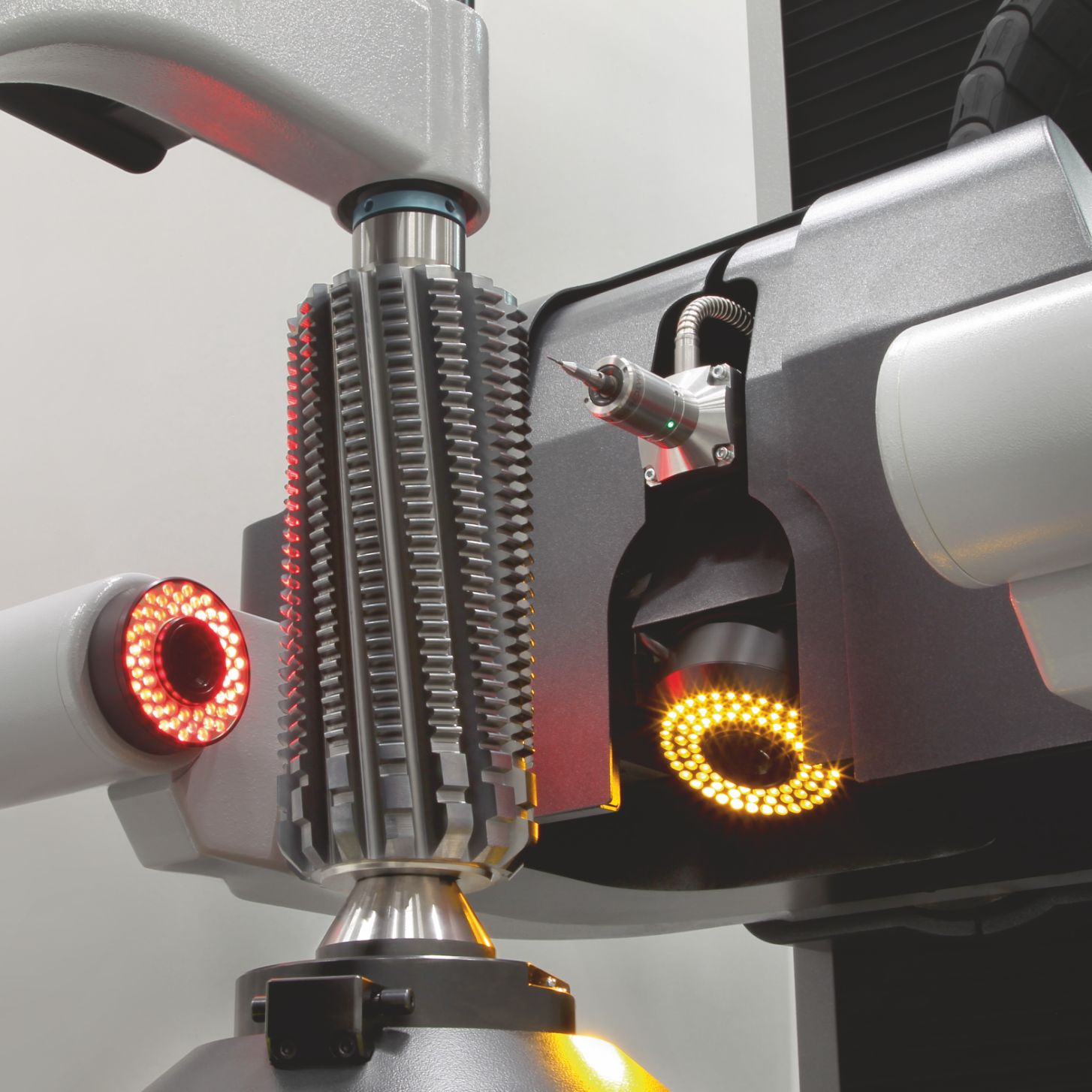

We Stand for Unmatched Precision

Thanks to the intelligent combination of image processing technology, CNC axes and measuring probes, all important parameters can be measured fully automatically. The distortion-free measurement and inspection of tools with pitches and precision tools of all kinds makes the ZOLLER »hobCheck« the universal genius.

We Stand for Unmatched Precision

Thanks to the intelligent combination of image processing technology, CNC axes and measuring probes, all important parameters can be measured fully automatically. The distortion-free measurement and inspection of tools with pitches and precision tools of all kinds makes the ZOLLER »hobCheck« the universal genius.

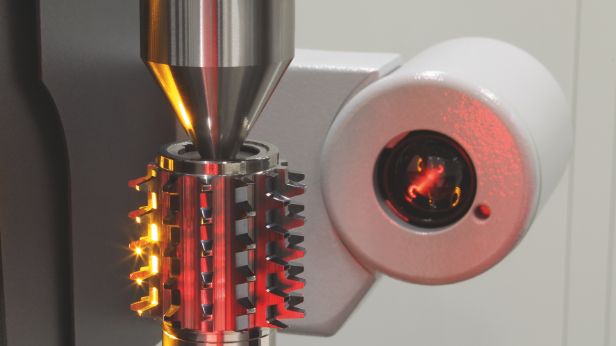

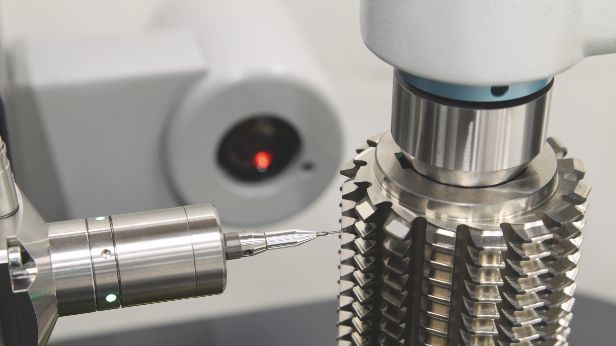

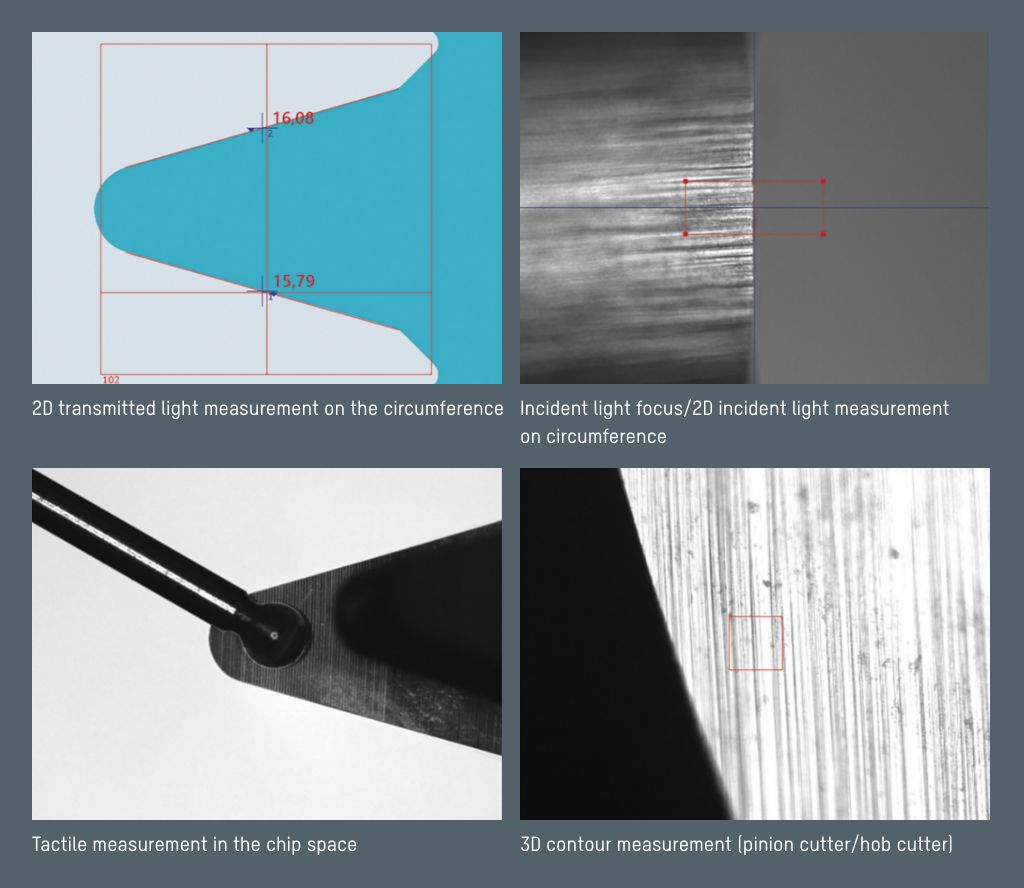

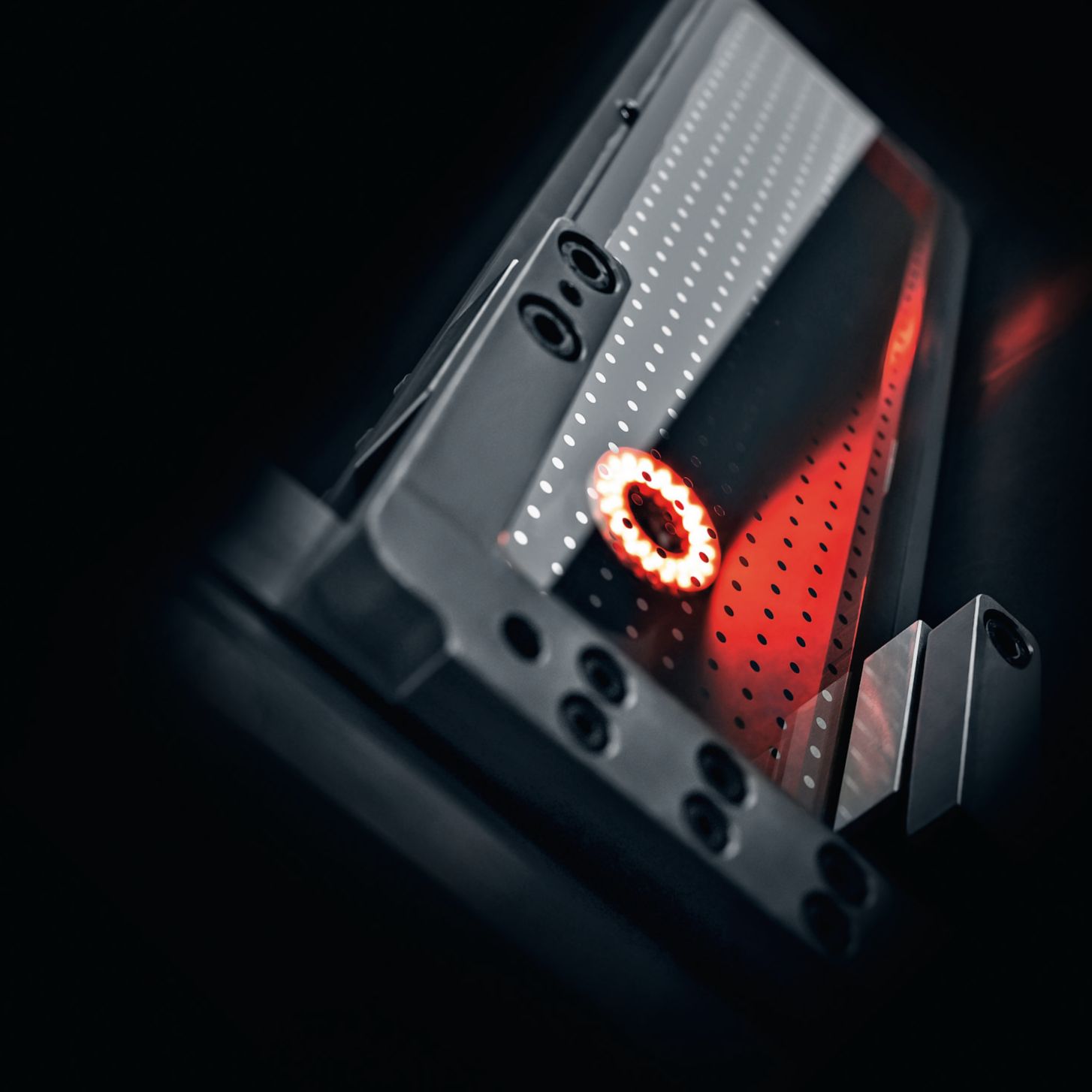

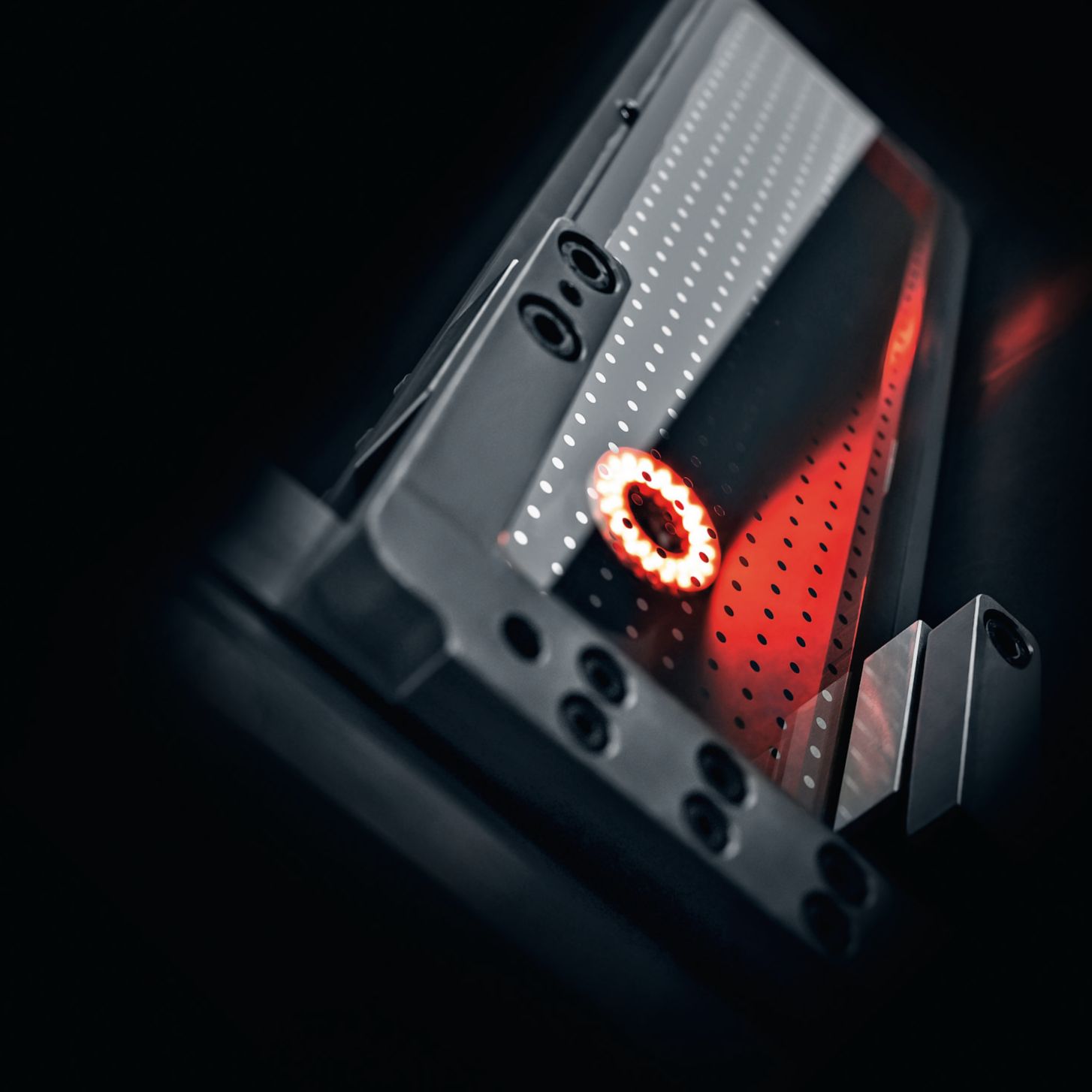

High-Precision Sensors

With the ZOLLER »hobCheck«, you can complete tactile measuring without contact in transmitted light and incident light. Equipped with a CNC-controlled swiveling optics carrier, electronic measuring probe and transmitted light and incident light image processing, parameters such as tooth profile, concentricity/wobble, pitch and many more can be measured automatically on hob cutters in accordance with DIN 3968.

High-Precision Sensors

With the ZOLLER »hobCheck«, you can complete tactile measuring without contact in transmitted light and incident light. Equipped with a CNC-controlled swiveling optics carrier, electronic measuring probe and transmitted light and incident light image processing, parameters such as tooth profile, concentricity/wobble, pitch and many more can be measured automatically on hob cutters in accordance with DIN 3968.

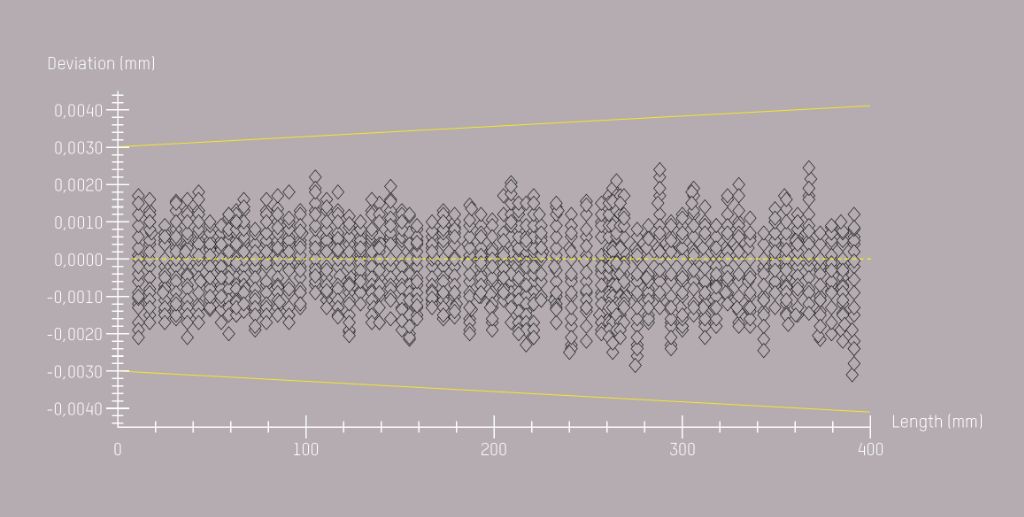

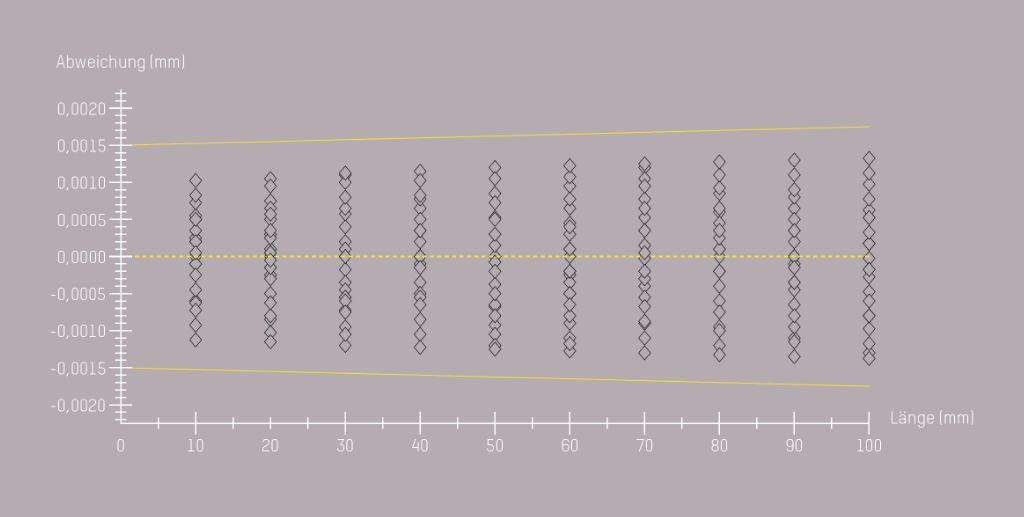

Guaranteed Quality

The demands in quality management are constantly increasing. Therefore, you must be able to rely on the constant measuring deviations of your machines. In ZOLLER measuring machines, high-precision calibration standards made of Borofloatglas® are used to determine the length measurement deviations based on the DIN EN ISO 10360 standard. In accordance with this standard, at least three measuring sequences (25,326 relationships) are carried out. With this procedure, the accuracy of the ZOLLER measuring machines is documented in two dimensions and can be traced at any time.

Guaranteed Quality

The demands in quality management are constantly increasing. Therefore, you must be able to rely on the constant measuring deviations of your machines. In ZOLLER measuring machines, high-precision calibration standards made of Borofloatglas® are used to determine the length measurement deviations based on the DIN EN ISO 10360 standard. In accordance with this standard, at least three measuring sequences (25,326 relationships) are carried out. With this procedure, the accuracy of the ZOLLER measuring machines is documented in two dimensions and can be traced at any time.

We Stand for Reliable Quality

100% made in Germany – that is our primary mission, and we work hard to ensure we achieve our goals. Thanks to an expansion of our production site in Pleidelsheim, Germany, our production is now even more efficient and economical.

The ZOLLER assembly – a team of specialized, competent employees from assembly and quality assurance ensure, day by day, that your »hobCheck« reaches your production facility in perfect condition. It only leaves the assembly line until all our employees are 100% satisfied, and the machine has the ZOLLER seal of quality.

We are proud of this.

We Stand for Reliable Quality

100% made in Germany – that is our primary mission, and we work hard to ensure we achieve our goals. Thanks to an expansion of our production site in Pleidelsheim, Germany, our production is now even more efficient and economical.

The ZOLLER assembly – a team of specialized, competent employees from assembly and quality assurance ensure, day by day, that your »hobCheck« reaches your production facility in perfect condition. It only leaves the assembly line until all our employees are 100% satisfied, and the machine has the ZOLLER seal of quality.

We are proud of this.