Software

»hobCheck«

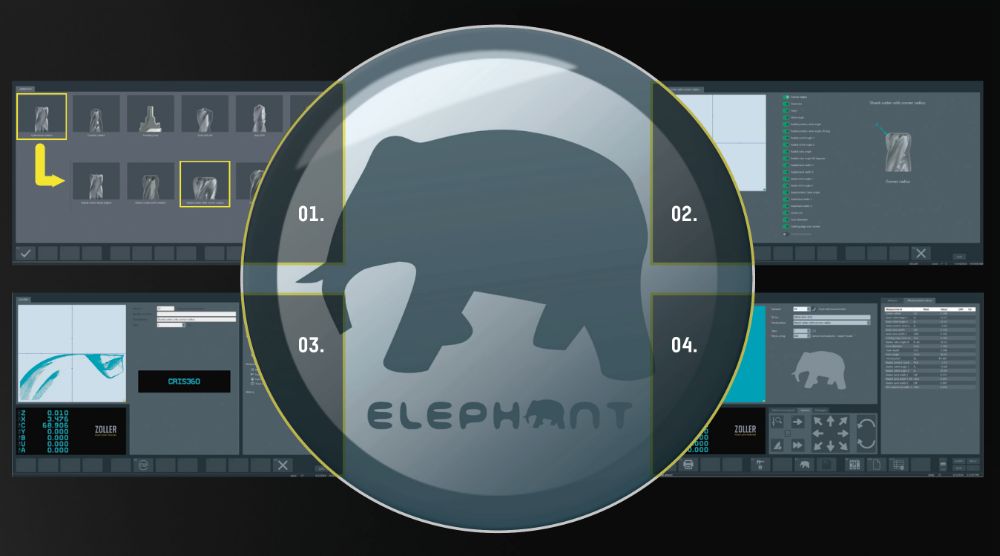

»elephant 2.0« – Extremely Easy to Operate

01. Select tool type, e.g. end mill > end mill with corner radius

02. Select the desired parameters

03. Active measurement e.g. cutting contour corner radius

04. Measurement results (measured fully automatically and without data input/programming)

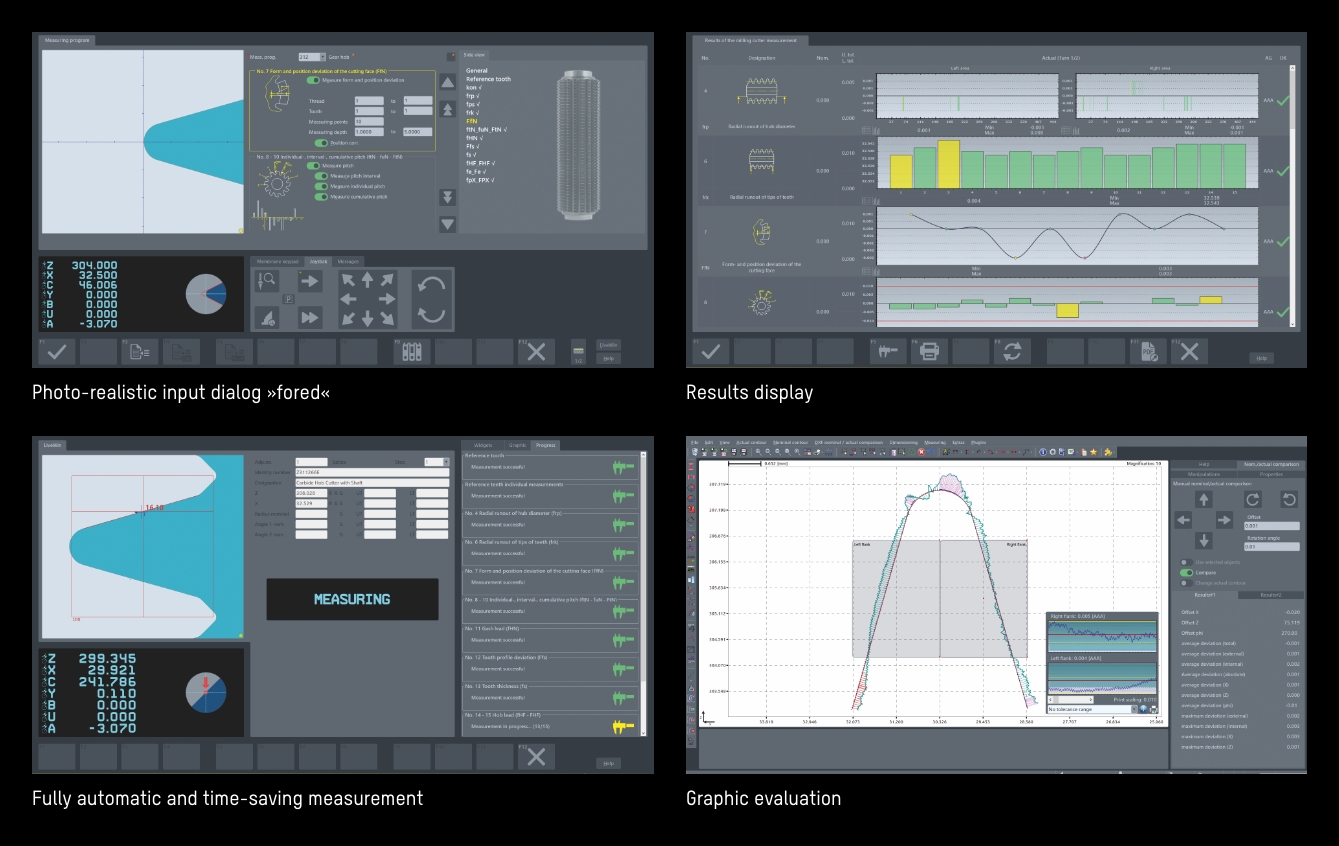

»hobCheck« – Clever, Fast, Perfect

Based on the ZOLLER »pilot 4.0« software, the »hobCheck« software makes the fast and μm-accurate measurement of gear cutting tools child’s play. Cylindrical hobs are measured fully automatically and evaluated in accordance with DIN 3968.

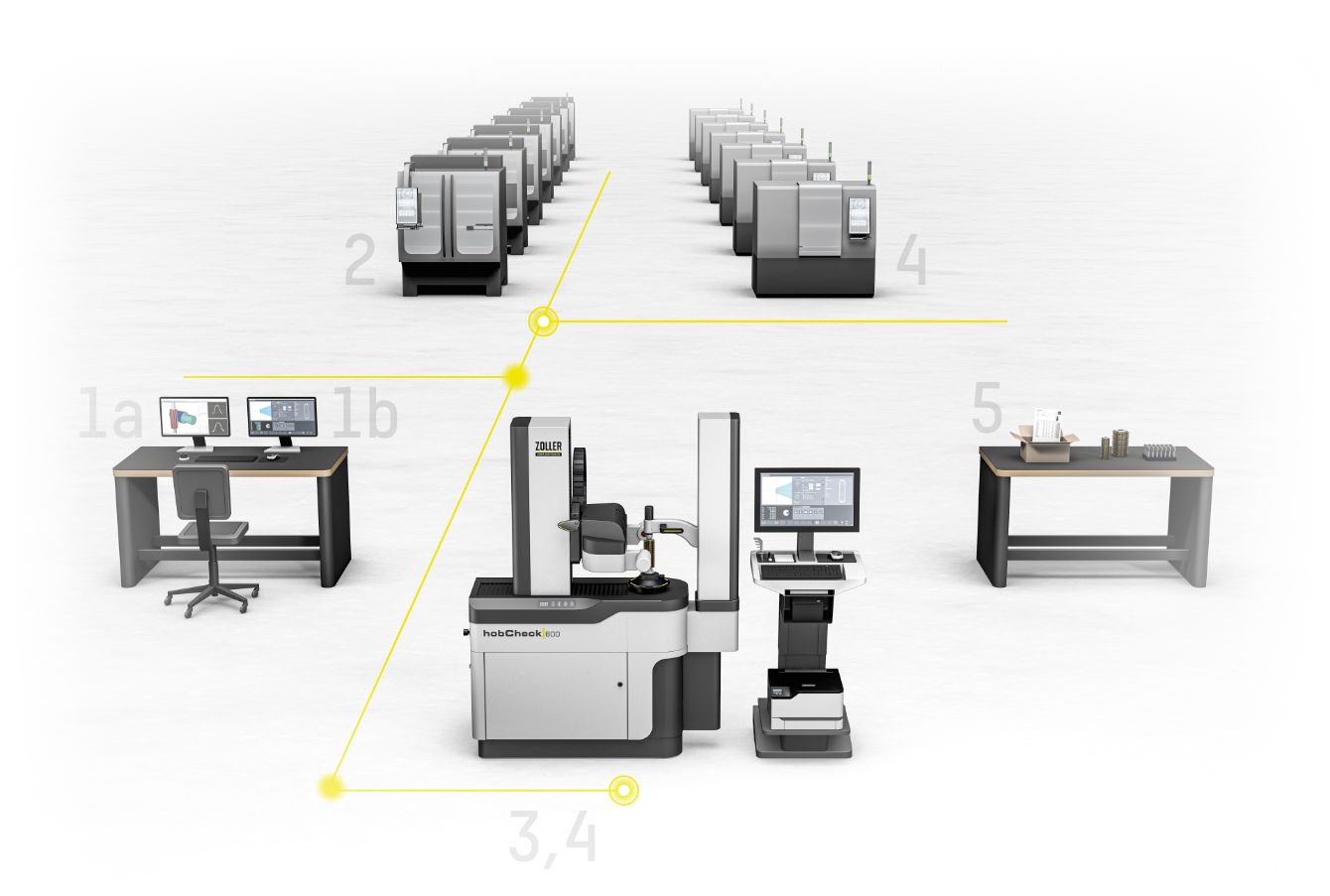

Pioneering Efficiency for your Grinding Shop

The highest potential for greater efficiency lies outside the grinding machine: ZOLLER Solutions stand for your future – we make you more successful. If you can manufacture your parts faster and more efficiently, you can work more economically and invest in the future. If economic progress is your goal, then ZOLLER is your partner.

Software Functions

For Maximum Performance

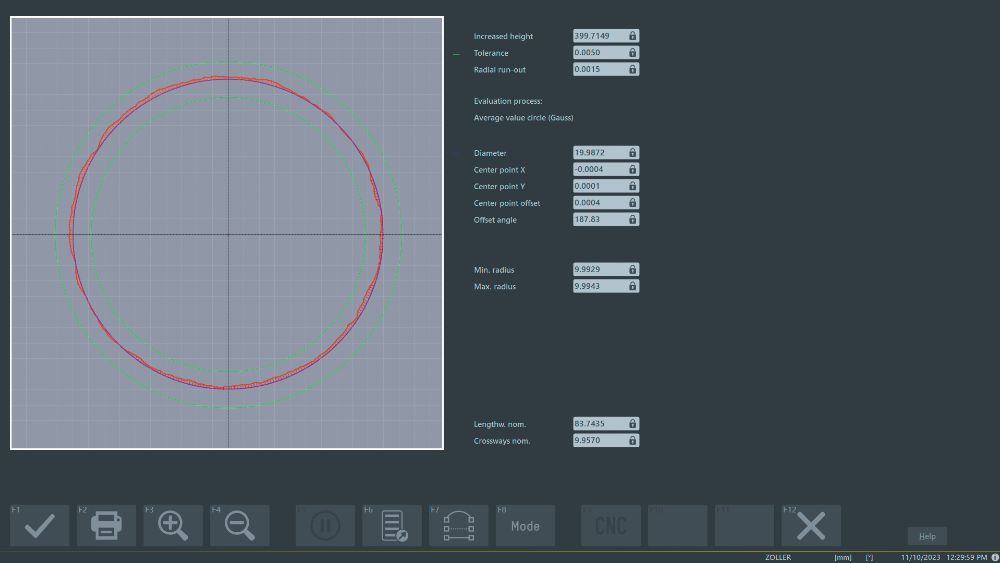

Concentricity check 360°

To automatically determine the radial run-out on circular surfaces (e.g. tool shank) and graphically evaluate the entire contour.

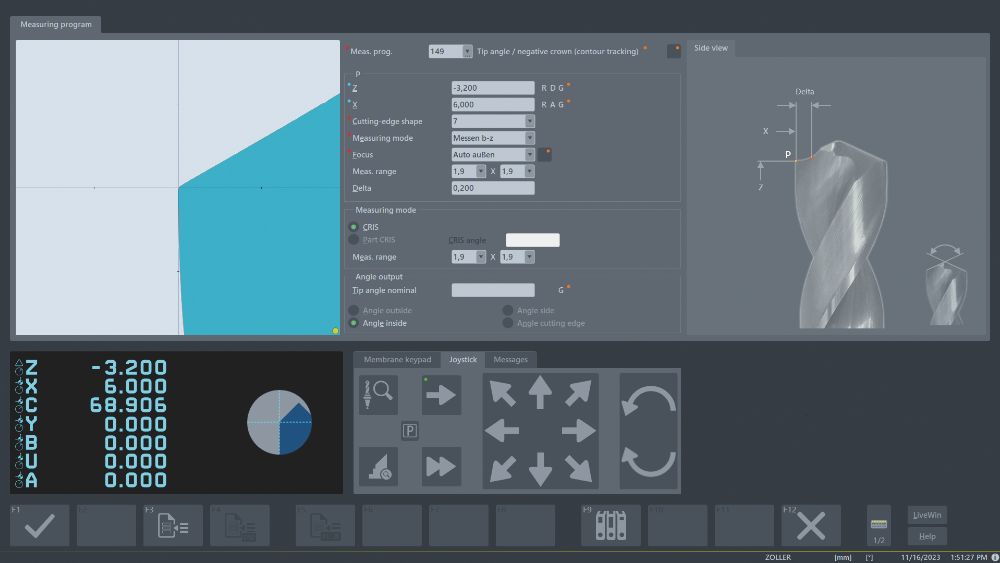

Point angle with hollow grinding

Is determined on drilling tools and hollow-ground tool cutting edges from the starting point (outside diameter) to the tool tip or the defined end point by contour tracking.

Flute/chip space scan

Automatically scans the flute/chip space contour without contact and displays it graphically.

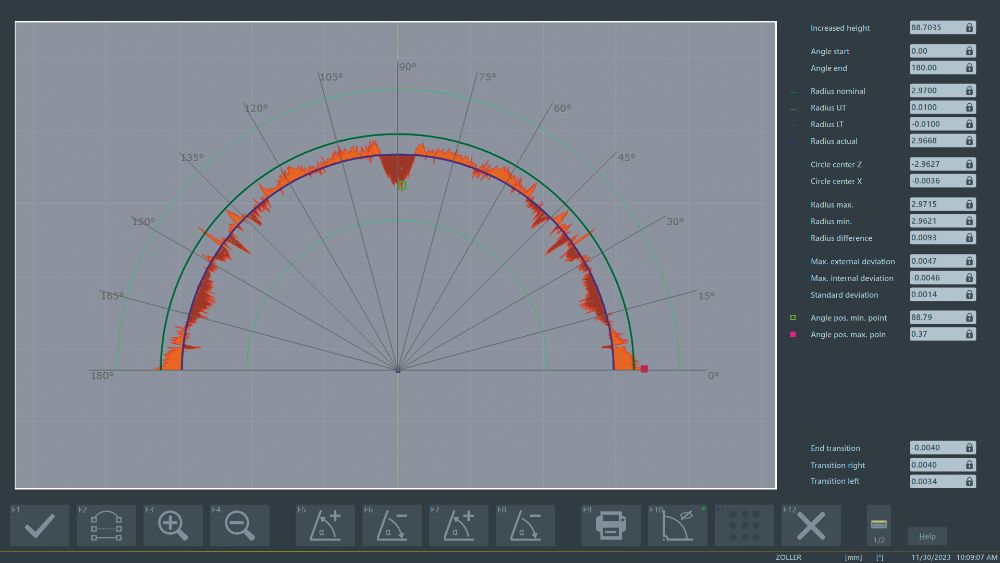

Radius contour »contur« with graphics

For automatic determination of concave and convex radii on the outer contour of tools including adjustable angle sectors with graphic evaluation.

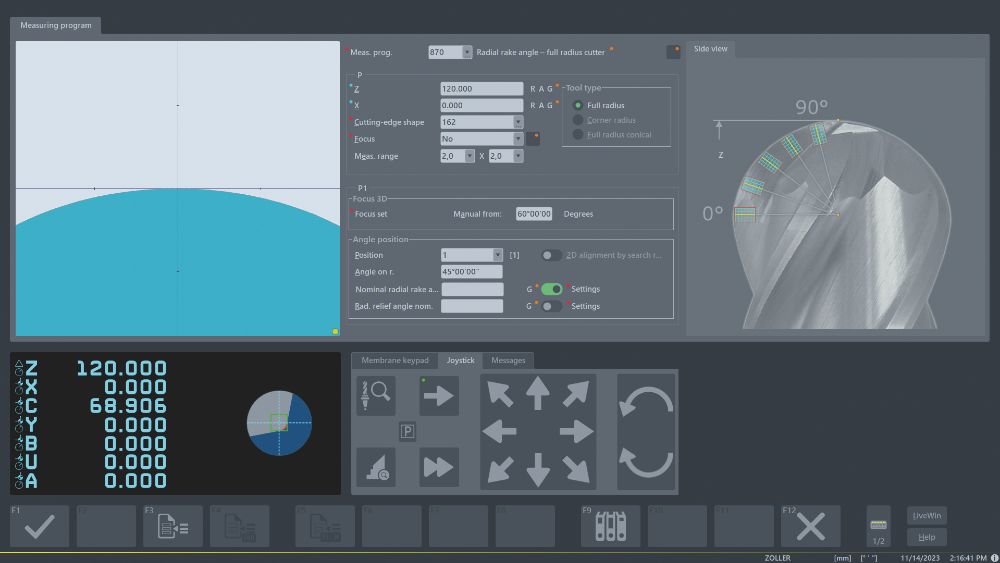

Rake angle on radius cutters

Determines the rake angle in the radius segment at the specified angles. Suitable for die, corner and full radius cutters.

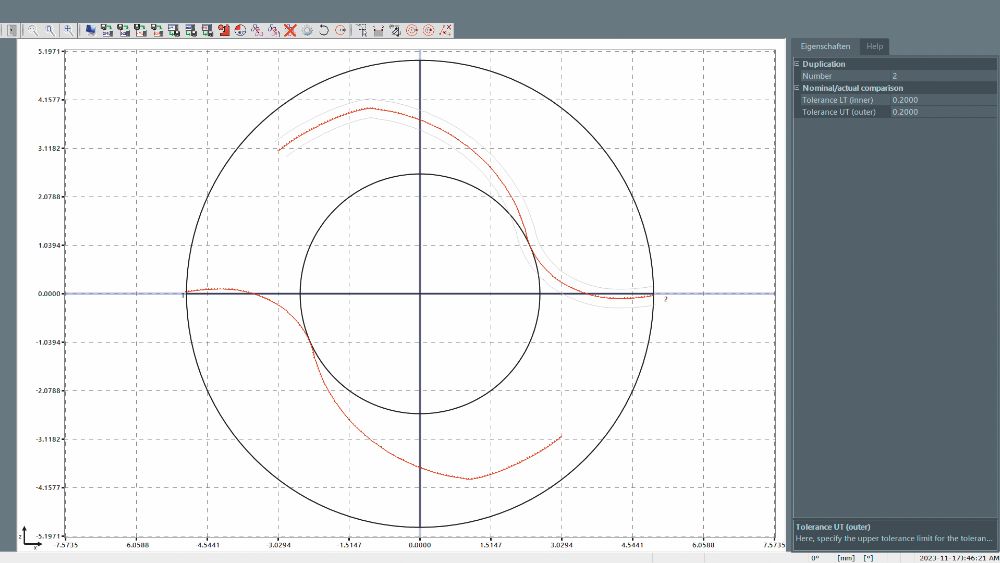

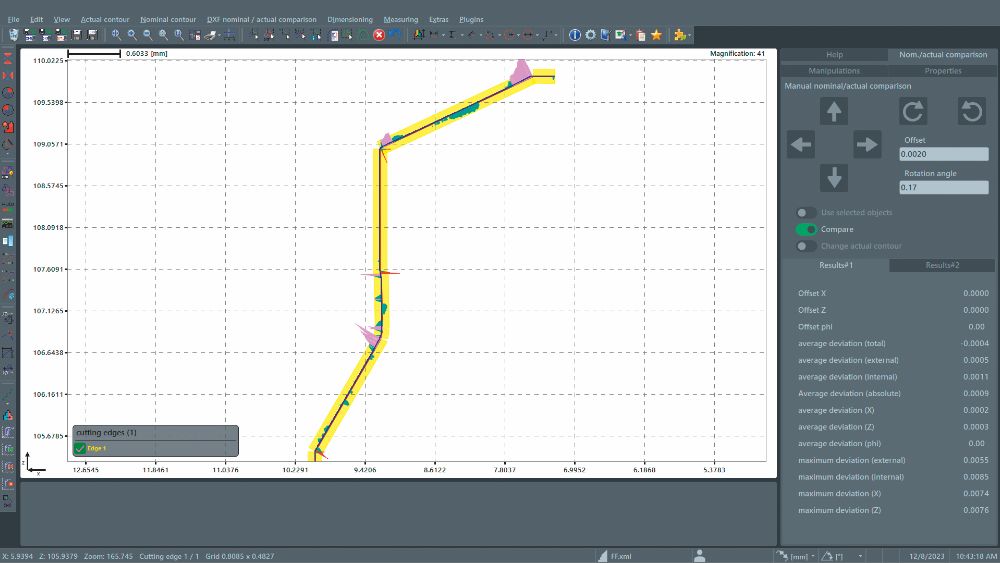

Contour measurement »lasso«

To scan any tool and workpiece contours and perform a nominal/actual comparison or dimensioning of the contour.

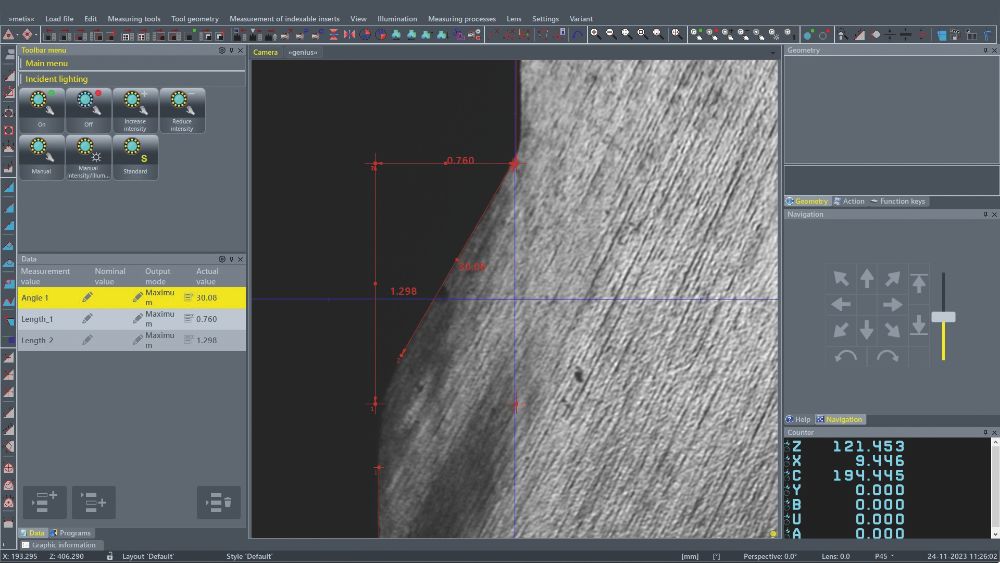

Tool analysis »metis«

Measures and documents any contours, radii, angles, distances and defects (wear) in incident light.

Editable inspection report »apus«

To display all measurement results including designations, nominal values, tolerances and much more in tabular form and flexibly in the layout.

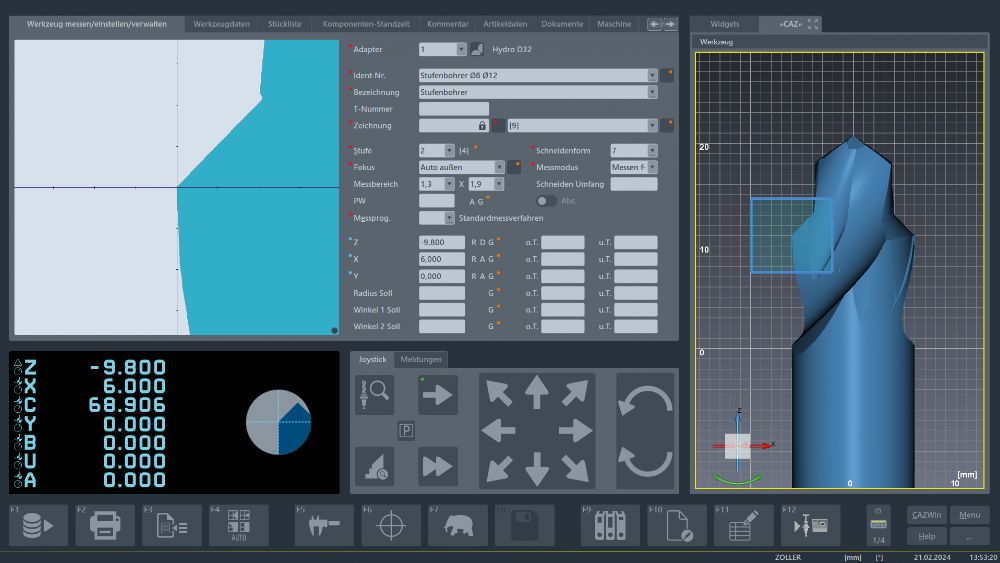

ZOLLER »caz«

The virtual measuring device for PC workstations for external creation of the inspection and measuring process including measuring programs, nominal values and tolerances using the 3D model of the tool before it is manufactured.