Featured

Technology

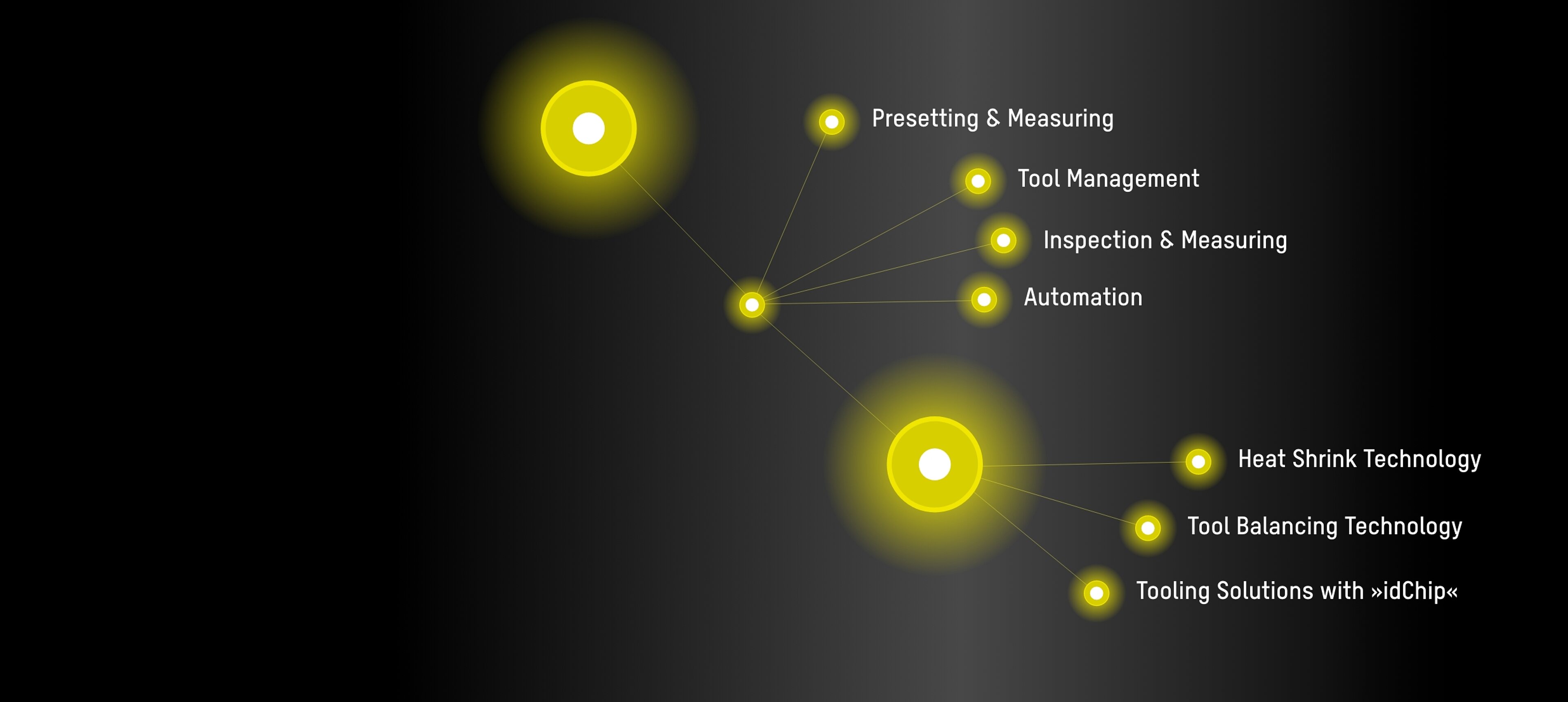

Discover your roadmap to greater efficiency

at the 2024 Open House & Technology Days!

Choose your roadmap to success

Tool Inspection & Measuring Solution

»genius«

The best-selling »genius« universal tool measuring and inspection machine is the perfect solution for quick, simple and precise measurement and inspection of your cutting tools.

It can easily handle everything from the quick testing of individual criteria to the fully automatic and operator-independent measurement of more than 100 parameters on standard and micro tools. Applications range from incoming inspection, in-house regrinding, research, benchmarking, wear analysis, tool setup, in-process control, final inspection to cutting tool certification and reverse engineering.

The »pilot 4.0« operating software equips users to run any measurement and inspection program for any requirement including typical tool measurement of helix angles, radial reliefs, lands, gash angles, head lengths, center offsets, chamfer heights and end face facets, to list but a few.

Tool Inspection & Measuring Solution

»genius«

The best-selling »genius« universal tool measuring and inspection machine is the perfect solution for quick, simple and precise measurement and inspection of your cutting tools.

It can easily handle everything from the quick testing of individual criteria to the fully automatic and operator-independent measurement of more than 100 parameters on standard and micro tools. Applications range from incoming inspection, in-house regrinding, research, benchmarking, wear analysis, tool setup, in-process control, final inspection to cutting tool certification and reverse engineering.

The »pilot 4.0« operating software equips users to run any measurement and inspection program for any requirement including typical tool measurement of helix angles, radial reliefs, lands, gash angles, head lengths, center offsets, chamfer heights and end face facets, to list but a few.

- Automation Solution

»roboBox«

The ZOLLER »roboBox« completely automates your tool assembly processes. This automation solution features heat-shrinking, cooling and measuring modules that guarantee accuracy within 10 microns.Learn more about this game-changer for the manufacturing industry at ZOLLER Open House & Technology Days!

- Automation Solution

»roboBox«

The ZOLLER »roboBox« completely automates your tool assembly processes. This automation solution features heat-shrinking, cooling and measuring modules that guarantee accuracy within 10 microns.Learn more about this game-changer for the manufacturing industry at ZOLLER Open House & Technology Days!

- Automation Solution

»roboSet 2«

The »roboSet 2« provides a fully automatic tool inspection process by working with a ZOLLER measuring machine to automate tool handling, cleaning and laser marking.

The automation cell's multi-pallet system and double gripper enable the »roboSet 2« to process and document large numbers of tools automatically. Eight pallets fit into the machine, and several orders can be combined on each one, even with different tool types and sizes.

The »roboSet 2« also provides ultrasonic and dry cleaning to guarantee every tool is free from microparticles, dust and cooling lubricants.

Automatic laser marking makes it easy to map the life cycle of a tool with precise, complete and traceable data. The laser unit in the »roboSet 2« writes a QR code on a tool's shank or base during inspection. If a reground tool is checked again, an integrated camera reads the QR code to identify the tool and update the data, creating a tool history with traceable measured values.

Operation using the »pilot 4.0« software is simple, thanks to the touch monitor, clear menus, large icons and configurable interfaces.

- Automation Solution

»roboSet 2«

The »roboSet 2« provides a fully automatic tool inspection process by working with a ZOLLER measuring machine to automate tool handling, cleaning and laser marking.

The automation cell's multi-pallet system and double gripper enable the »roboSet 2« to process and document large numbers of tools automatically. Eight pallets fit into the machine, and several orders can be combined on each one, even with different tool types and sizes.

The »roboSet 2« also provides ultrasonic and dry cleaning to guarantee every tool is free from microparticles, dust and cooling lubricants.

Automatic laser marking makes it easy to map the life cycle of a tool with precise, complete and traceable data. The laser unit in the »roboSet 2« writes a QR code on a tool's shank or base during inspection. If a reground tool is checked again, an integrated camera reads the QR code to identify the tool and update the data, creating a tool history with traceable measured values.

Operation using the »pilot 4.0« software is simple, thanks to the touch monitor, clear menus, large icons and configurable interfaces.

- Tool Presetting & Measuring Solution

»smileCompact«

Experience the epitome of ZOLLER’s quality standards in manufacturing with the »smileCompact«. This presetting machine is not just about simplicity of operation; it also provides everything you need for fast and accurate presetting and measuring standard tools offline.

Designed for ergonomic use in the heart of the manufacturing environment, the »smileCompact« delivers precision tool presetting systems. It measures tool length, diameter, radius, angle, concentricity and axial run-out in seconds.

The tool’s cutting edge is vividly displayed on the vertical 13-inch panel PC, providing immediate and precise results without any training requirements. The »smileCompact« is your perfect entry point into the world of ZOLLER.

- Tool Presetting & Measuring Solution

»smileCompact«

Experience the epitome of ZOLLER’s quality standards in manufacturing with the »smileCompact«. This presetting machine is not just about simplicity of operation; it also provides everything you need for fast and accurate presetting and measuring standard tools offline.

Designed for ergonomic use in the heart of the manufacturing environment, the »smileCompact« delivers precision tool presetting systems. It measures tool length, diameter, radius, angle, concentricity and axial run-out in seconds.

The tool’s cutting edge is vividly displayed on the vertical 13-inch panel PC, providing immediate and precise results without any training requirements. The »smileCompact« is your perfect entry point into the world of ZOLLER.

- Tool Inspection & Measuring Solution

»smartCheck«

Whether a manual or 3-axis, CNC version, the »smartCheck« is ZOLLER's powerful universal measuring machine for all cutting tools. Check your tools efficiently before and after grinding to fulfill DIN EN ISO 9000 guidelines.

With the swiveling incident light image processing software, you can inspect, measure and document axial and radial geometries of tools easily in a single click without expert-level knowledge.

You profit directly from at least a 25% productivity increase with your CNC grinding machines simply by measuring your tools before regrinding.

- Tool Inspection & Measuring Solution

»smartCheck«

Whether a manual or 3-axis, CNC version, the »smartCheck« is ZOLLER's powerful universal measuring machine for all cutting tools. Check your tools efficiently before and after grinding to fulfill DIN EN ISO 9000 guidelines.

With the swiveling incident light image processing software, you can inspect, measure and document axial and radial geometries of tools easily in a single click without expert-level knowledge.

You profit directly from at least a 25% productivity increase with your CNC grinding machines simply by measuring your tools before regrinding.

- Tool Presetting & Measuring Solution

»venturion«

The ZOLLER »venturion« is a premium presetting and measuring machine that blends precision, flexibility and process reliability in a robust solution that can easily be customized.

Made from a light alloy developed for measuring machines, the »venturion« features high-quality, brand-name components, including a Heidenhain optical measuring system and Bosch/Festo pneumatic elements.

A high-precision spindle guarantees micron-accurate tool holding, and a universal toolholder adapter changing system allows the spindle to handle almost any toolholding system. Designed for quick exchanges, the »venturion« allows a toolholder to be changed in 10 seconds with an accuracy of less than one micron.

Operating on the world-class »pilot« image processing software, machines in the »venturion« series offer photorealistic input dialogs, automatic cutting edge detection, automatic zero-point monitoring and more. Modules can be added for tool inspection, center height measuring, measuring reamers or heat-shrinking tools.

Ergonomic features such as a one-hand control handle and a variable control unit allow the operator to work comfortably, and with 180 degrees of accessibility, it is much easier to change tools.

- Tool Presetting & Measuring Solution

»venturion«

The ZOLLER »venturion« is a premium presetting and measuring machine that blends precision, flexibility and process reliability in a robust solution that can easily be customized.

Made from a light alloy developed for measuring machines, the »venturion« features high-quality, brand-name components, including a Heidenhain optical measuring system and Bosch/Festo pneumatic elements.

A high-precision spindle guarantees micron-accurate tool holding, and a universal toolholder adapter changing system allows the spindle to handle almost any toolholding system. Designed for quick exchanges, the »venturion« allows a toolholder to be changed in 10 seconds with an accuracy of less than one micron.

Operating on the world-class »pilot« image processing software, machines in the »venturion« series offer photorealistic input dialogs, automatic cutting edge detection, automatic zero-point monitoring and more. Modules can be added for tool inspection, center height measuring, measuring reamers or heat-shrinking tools.

Ergonomic features such as a one-hand control handle and a variable control unit allow the operator to work comfortably, and with 180 degrees of accessibility, it is much easier to change tools.

- Tool Presetting & Measuring Solution

»hyperion«

Whether you’re looking to preset and measure tools for lathe machines, processing centers or milling centers, the »hyperion« is your go-to solution for turning.

Due to a specially mounted revolving table, the »hyperion« caters to almost all tool-holding requirements quickly, accurately and reliably. With 100% prepared and inspected tools, you’ll experience the immediate benefits that come standard with ZOLLER: improved efficiency, better parts, higher productivity and greater profits.

- Tool Presetting & Measuring Solution

»hyperion«

Whether you’re looking to preset and measure tools for lathe machines, processing centers or milling centers, the »hyperion« is your go-to solution for turning.

Due to a specially mounted revolving table, the »hyperion« caters to almost all tool-holding requirements quickly, accurately and reliably. With 100% prepared and inspected tools, you’ll experience the immediate benefits that come standard with ZOLLER: improved efficiency, better parts, higher productivity and greater profits.

- Tool Inspection & Measuring Solution

»hobCheck«

The »hobCheck« opens up never-before-seen possibilities for the fully automatic, efficient and complete measurement of milling cutters of all sizes.

With transmitted light image processing, an incident light camera and a measuring sensor, more than 15 parameters can be measured, including tooth profile, concentricity, wobble, pitch, shape and position.

The analysis of more than 200 measured values, the calculation of the quality classes and the graphical record are all fully automatic. In addition, the »hobCheck« offers a comfortable convenient wear and tear evaluation on the tooth head for regrinding.

- Tool Inspection & Measuring Solution

»hobCheck«

The »hobCheck« opens up never-before-seen possibilities for the fully automatic, efficient and complete measurement of milling cutters of all sizes.

With transmitted light image processing, an incident light camera and a measuring sensor, more than 15 parameters can be measured, including tooth profile, concentricity, wobble, pitch, shape and position.

The analysis of more than 200 measured values, the calculation of the quality classes and the graphical record are all fully automatic. In addition, the »hobCheck« offers a comfortable convenient wear and tear evaluation on the tooth head for regrinding.

- Tool Presetting & Measuring Solution

»torquematic«

Fully Automatic Torquing

The »torquematic« presetting and measuring machine from ZOLLER allows tools with collet chucks to be automatically set to length, clamped to a predefined torque and measured. The automatic torquing station clamps tools without any effort. Your employees will be thrilled at the ease of operation of this machine!

- Tool Presetting & Measuring Solution

»torquematic«

Fully Automatic Torquing

The »torquematic« presetting and measuring machine from ZOLLER allows tools with collet chucks to be automatically set to length, clamped to a predefined torque and measured. The automatic torquing station clamps tools without any effort. Your employees will be thrilled at the ease of operation of this machine!

- Tool Presetting, Measuring & Heat-Shrinking Solution

»redomatic«

The »redomatic« is not just a machine; it’s a multifaceted tool that excels in the three disciplines of presetting, measuring and heat-shrinking.

The »redomatic« is equipped with a four-axis CNC control unit, autofocus, a revolving table for quick changes between tool holder types, an induction coil, tailstock and a cooling system.

Thanks to its unique automatic length adjustment feature, this machine is designed to shrink tools quickly and easily, achieving at least ± 10-micron accuracy. The heat-shrinking and cooling process takes just 35 seconds, offering manufacturers remarkable time savings and preserved tool holder life due to minimal energy usage.

- Tool Presetting, Measuring & Heat-Shrinking Solution

»redomatic«

The »redomatic« is not just a machine; it’s a multifaceted tool that excels in the three disciplines of presetting, measuring and heat-shrinking.

The »redomatic« is equipped with a four-axis CNC control unit, autofocus, a revolving table for quick changes between tool holder types, an induction coil, tailstock and a cooling system.

Thanks to its unique automatic length adjustment feature, this machine is designed to shrink tools quickly and easily, achieving at least ± 10-micron accuracy. The heat-shrinking and cooling process takes just 35 seconds, offering manufacturers remarkable time savings and preserved tool holder life due to minimal energy usage.

- Tool Management Solutions

Tool Management Solutions

ZOLLER's tool management software and hardware make production more efficient by providing complete, accurate tool data.

Tapping into this data, all stored in a single-source database, is the key to decreasing setup times, increasing machine tool uptime, extending tool life and organizing and tracking a facility's inventory.

ZOLLER's robust tool management software provides transparent tool storage and circulation data to help you prevent costly production bottlenecks from missing or misplaced tools.

Three tiers of software packages — bronze, silver and gold — offer escalating levels of tool management, warehouse management and full cost control.

- Tool Management Solutions

Tool Management Solutions

ZOLLER's tool management software and hardware make production more efficient by providing complete, accurate tool data.

Tapping into this data, all stored in a single-source database, is the key to decreasing setup times, increasing machine tool uptime, extending tool life and organizing and tracking a facility's inventory.

ZOLLER's robust tool management software provides transparent tool storage and circulation data to help you prevent costly production bottlenecks from missing or misplaced tools.

Three tiers of software packages — bronze, silver and gold — offer escalating levels of tool management, warehouse management and full cost control.

- Tool Inspection & Measuring Solution

»pomBasic«

The ZOLLER »pomBasic« is the top inspection solution for process-related measuring and inspection of drills, milling cutters and counterbores in incident light.

Thanks to its compact and universal design, the »pomBasic« can be used in the measuring lab, incoming tool inspection or grinding shop. It is also the ideal machine for the shop floor and can be placed directly alongside the CNC grinding machine. Simply insert your tool, start up, measure and you’re done.

With automatic edge detection for high accuracy, assistant-supported measuring procedures and inspection reports in a single click, nothing is quicker or easier than the »pomBasic« solution.

- Tool Inspection & Measuring Solution

»pomBasic«

The ZOLLER »pomBasic« is the top inspection solution for process-related measuring and inspection of drills, milling cutters and counterbores in incident light.

Thanks to its compact and universal design, the »pomBasic« can be used in the measuring lab, incoming tool inspection or grinding shop. It is also the ideal machine for the shop floor and can be placed directly alongside the CNC grinding machine. Simply insert your tool, start up, measure and you’re done.

With automatic edge detection for high accuracy, assistant-supported measuring procedures and inspection reports in a single click, nothing is quicker or easier than the »pomBasic« solution.

- Tool Management Solutions

Smart cabinets

ZOLLER offers smart storage solutions to manage all your cutting tools, components and accessories. All these storage solutions are connected to ZOLLER's tool management software, letting you monitor inventory 24/7 and benefit from intelligent tool management. They include:

- »toolOrganizer« storage for cutting tools and small parts

- »keeper« vertical storage for complete tool and toolholders

- »toolStation« workbench for optimal tool assembly

- »twister« storage for tool components and accessory parts

- ZOLLER tool cart for convenient tool transport

- Tool Management Solutions

Smart cabinets

ZOLLER offers smart storage solutions to manage all your cutting tools, components and accessories. All these storage solutions are connected to ZOLLER's tool management software, letting you monitor inventory 24/7 and benefit from intelligent tool management. They include:

- »toolOrganizer« storage for cutting tools and small parts

- »keeper« vertical storage for complete tool and toolholders

- »toolStation« workbench for optimal tool assembly

- »twister« storage for tool components and accessory parts

- ZOLLER tool cart for convenient tool transport