Options & Accessories

Automatic sliding door

Before starting the measuring process, the sliding door of the measuring machine can be conveniently and easily closed pneumatically via the software and opened again once the measuring process is completed.

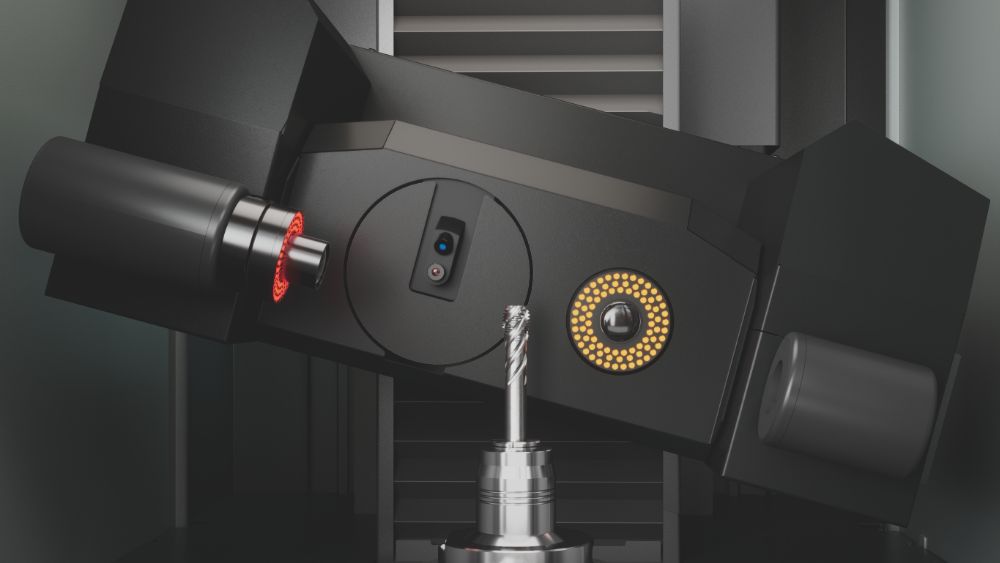

»orthoScan«

The swiveling multi-sensor optics carrier »orthoScan« always finds the perfect viewing angle on the tool. This means that the cutting edge geometries of tools with a pitch, such as taps or hob cutters, can be measured without distortion.

Tailstock counter point

With a clamping range of 300 mm for holding tools between points and for measuring exclusively using the snap gauge principle. The tailstock is removable and equipped with high-precision Hirth serration as an interchangeable interface.

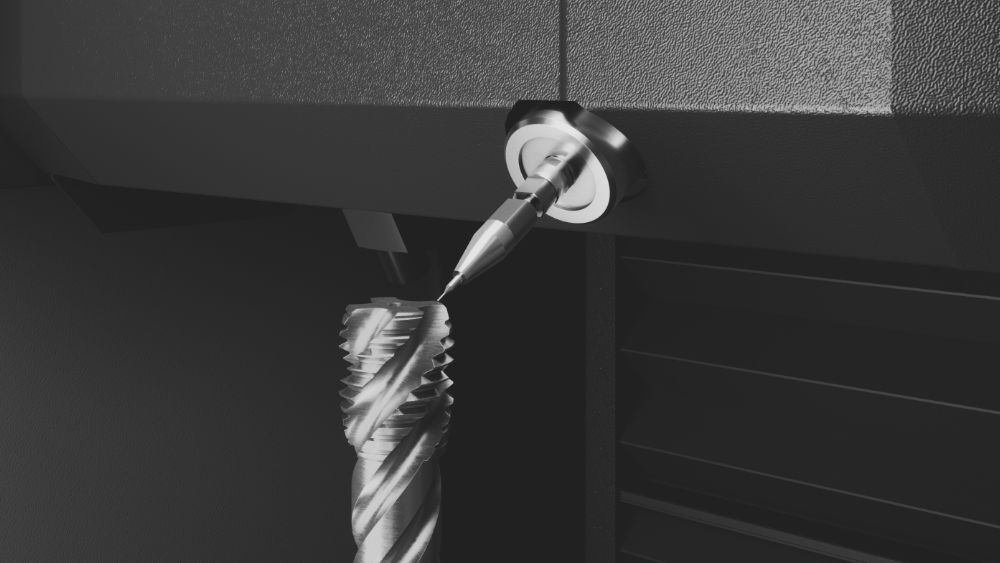

Scanning measuring probe

For electronic tactile measurement of, for example, the thread relief on taps. Available with probe inserts from D 0.01" to D 0.08" (D 0.3 mm to D 2 mm).

Measuring and inspection tools

For periodic on-site inspection of the measuring machine and to verify the accuracy of transmitted and incident light measurements, ZOLLER offers appropriate measuring and inspection tools for your measuring machine, such as test mandrels, diameter and angle test gauges.

Safety package

Important operating elements are located on the front of the measuring machine. This means you always have unrestricted access to the emergency stop switch, the reset button, the membrane keypad and the button for starting measurement processes.

Manual RFID read/write station »mslz«

For manual writing/reading of the code carrier on the tool holder via a handheld reader.

UPS system

The UPS system for uninterruptible power supply ensures that your computer is shut down properly in the case of a power failure to prevent data loss. Mains voltages of 230 V~ (Europe) and 120 V~ (USA) are available.

Sensors configuration

Optics transmitted light

Transmitted light camera HR70, BF approx. 0.15" x 0.14" (4.0 x 3.6 mm2)

Base model

Transmitted light camera 5 Mpx, BF approx. 0.21" x 0.19" (5.5 x 5.0 mm2)

optional

Transmitted light camera WF, BF approx. 0.61" x 0.55" (15.5 x 14.1 mm2)

optional

Optics incident light

Incident light camera HR70 Standard, BF approx. 0.04" x 0.03" (1.1 x 1.0 mm2)

Base model

Incident light camera HR70 Micro, BF approx. 0.01" x 0.01" (0.4 x 0.4 mm2)

optional

»zep« sensor (Cutting edge preparation)

optional

»zep-R« sensor (Cutting edge preparation/roughness)

optional

»Z3dCam« sensor (Digitization)

optional

Tactile

Scanning measuring probe

optional

Measuring machine configuration

Spindle

High-precision spindle »tcs«

Base model

High-precision spindle »ahd«

optional

Hollow encoder

Base model

Linear drive

Positive locking ball screw

Base model

X-, Y-axis in cross table design

Base model

Optics drive

Swivel axis incident light

Base model

Swivel axis incident light & transmitted light

optional

Vibration damping

Integrated, active with level control

Base model

Leveling element on machine feet

Base model

Material

Hard stone

Base model