Consistent Processes

Your data accompanies you through all processes without bumps and stumbles. This is possible because ZOLLER has reliable and automated solutions for critical points such as data transfer or data preparation in controller format.

Consistent Processes

Your data accompanies you through all processes without bumps and stumbles. This is possible because ZOLLER has reliable and automated solutions for critical points such as data transfer or data preparation in controller format.

»idChip«

Unique Tool Identification

With the »idChip«, you make each of your tools ready for automated and error-free data transfer along your tool processes. The »idChip« carries a code that uniquely identifies a complete tool in the z.One database. By scanning the »idChip« with »zidCode«, the associated tool data is retrieved and transferred to the machine control system, for example.

The chip is firmly glued into the ZOLLER tool-holding fixtures and is additionally held in the holder by special grooves. The chip is therefore securely fixed even in fast rotating tools.

»idChip«

Unique Tool Identification

With the »idChip«, you make each of your tools ready for automated and error-free data transfer along your tool processes. The »idChip« carries a code that uniquely identifies a complete tool in the z.One database. By scanning the »idChip« with »zidCode«, the associated tool data is retrieved and transferred to the machine control system, for example.

The chip is firmly glued into the ZOLLER tool-holding fixtures and is additionally held in the holder by special grooves. The chip is therefore securely fixed even in fast rotating tools.

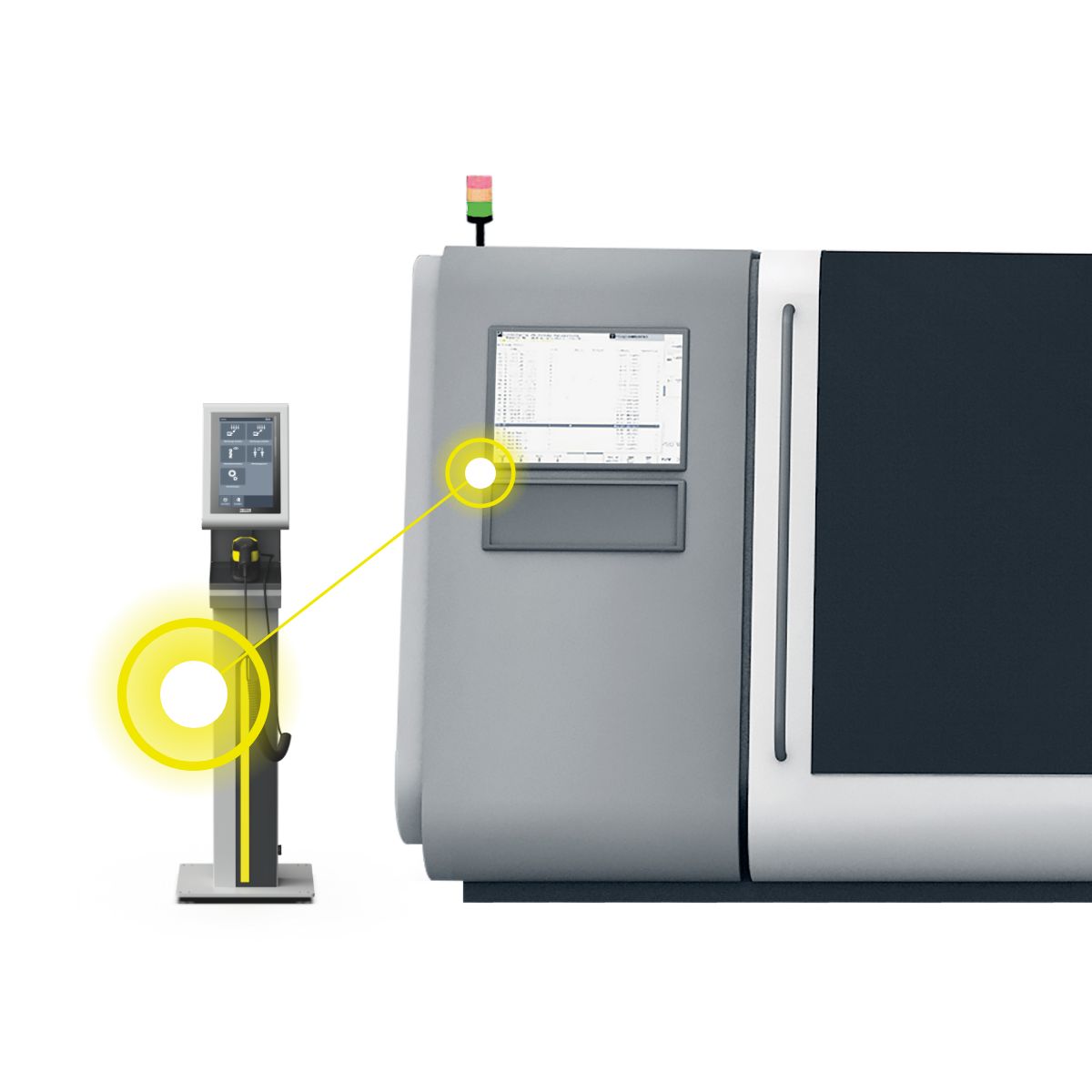

»zidCode«

Data Transfer with 45 % Time Saving

By scanning, »zidCode« transfers all relevant tool data in fractions of a second. Zero errors, no crashes, no wear due to incorrect data input on the control panel of the CNC machine.

Internal comparative measurements have shown: Even when setting up 6 tools, you save around 45 % with »zidCode«.

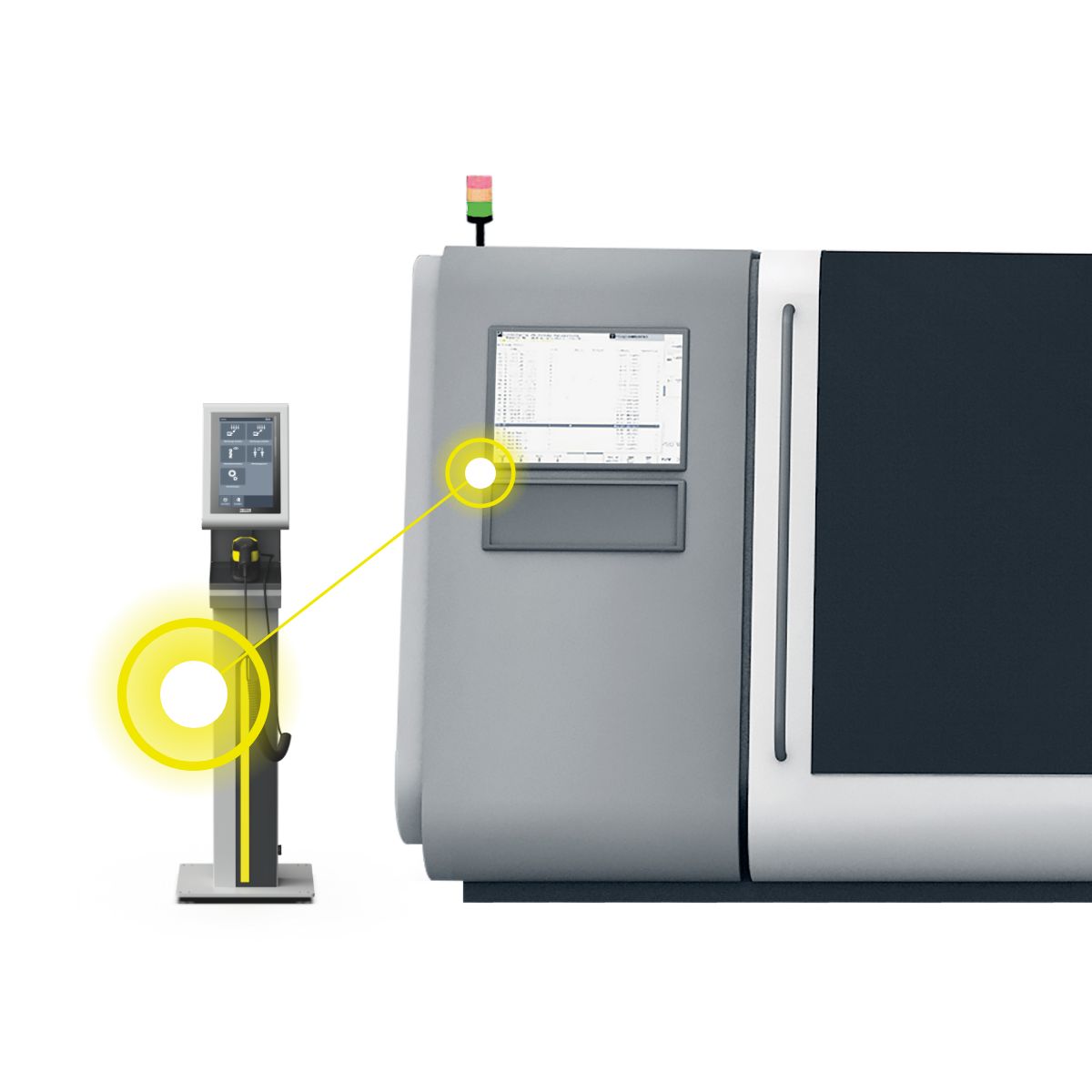

»zidCode«

Data Transfer with 45 % Time Saving

By scanning, »zidCode« transfers all relevant tool data in fractions of a second. Zero errors, no crashes, no wear due to incorrect data input on the control panel of the CNC machine.

Internal comparative measurements have shown: Even when setting up 6 tools, you save around 45 % with »zidCode«.

Interfaces to control systems

Bidirectional Data Flow

The technology »z.DMI« enables bidirectional data transfer between the z.One database and your production machines. This allows you to automatically write tool life data back to the database after each production run, for example. Cutting companies, tool manufacturers and grinding specialists benefit from continuously updated tool data.

»z.DMI« is compatible with control systems of Okuma, Makino, Fanuc, Heidenhain, Siemens, Mazak and Matsuura.

Interfaces to control systems

Bidirectional Data Flow

The technology »z.DMI« enables bidirectional data transfer between the z.One database and your production machines. This allows you to automatically write tool life data back to the database after each production run, for example. Cutting companies, tool manufacturers and grinding specialists benefit from continuously updated tool data.

»z.DMI« is compatible with control systems of Okuma, Makino, Fanuc, Heidenhain, Siemens, Mazak and Matsuura.

»caz«

Turn Data into Measuring Programs

The software module »caz« (computer aided ZOLLER) is a virtual measuring machine that tool manufacturers use to generate and simulate measuring sequences for newly developed tools or special tools.

These measuring sequences are then transferred to the »pilot 4.0« software. Your ZOLLER presetting and measuring machine is then ready for the new tool.

»caz«

Turn Data into Measuring Programs

The software module »caz« (computer aided ZOLLER) is a virtual measuring machine that tool manufacturers use to generate and simulate measuring sequences for newly developed tools or special tools.

These measuring sequences are then transferred to the »pilot 4.0« software. Your ZOLLER presetting and measuring machine is then ready for the new tool.

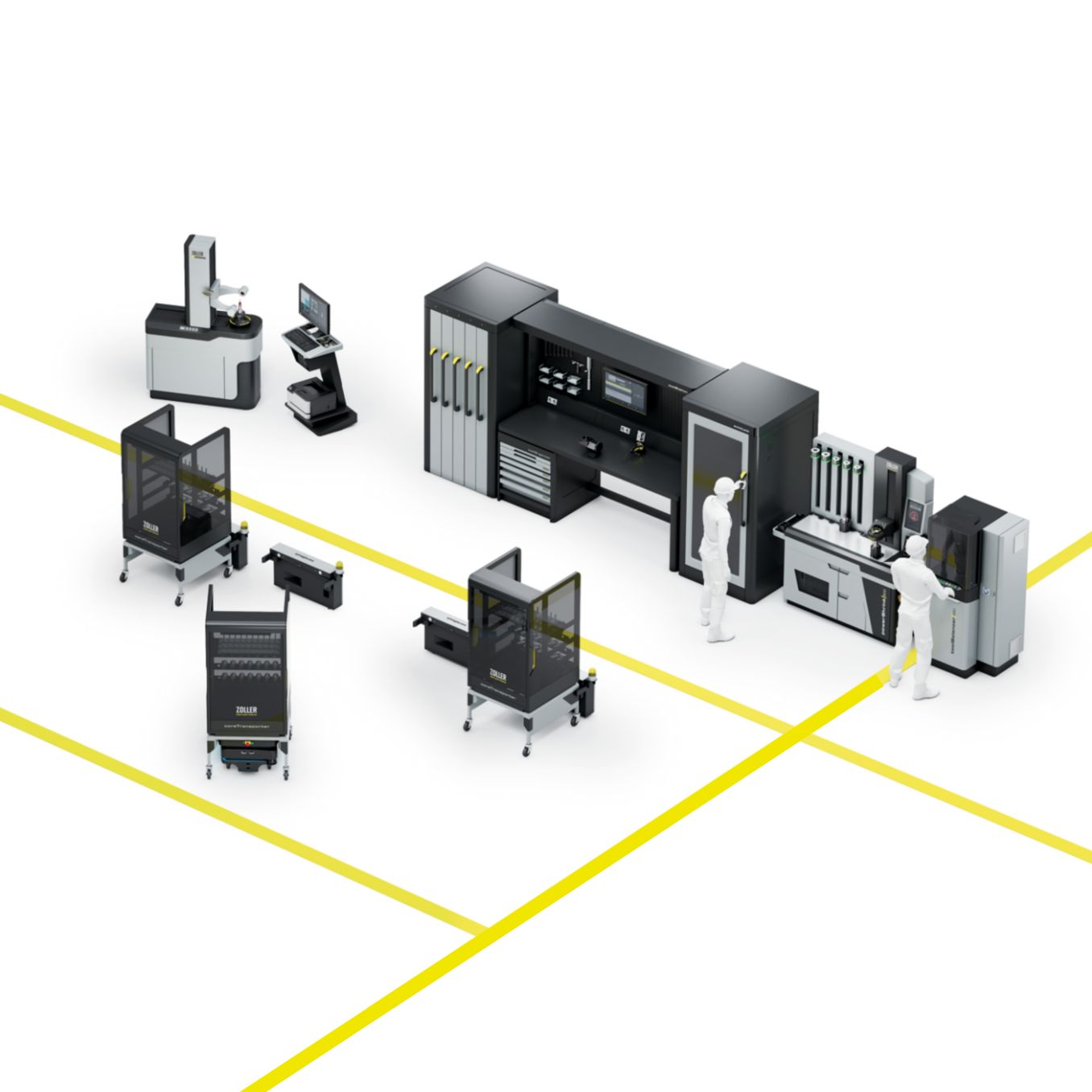

Preparing for the future

Data Leads to Automation

If you establish the systematic tool management of ZOLLER throughout the entire process, you create all the important prerequisites for taking the next step: Automation.

At ZOLLER, tool management, database, software, data transfer and data quality are prepared in such a way that you can start automating processes at any time. With ZOLLER, you automate:

- Tool assembly

- Presetting and measuring

- Tool inspection and documentation

- Tool storage and dispensing

- Tool logistics on the shop floor

- Cleaning, laser marking, shrinking and more

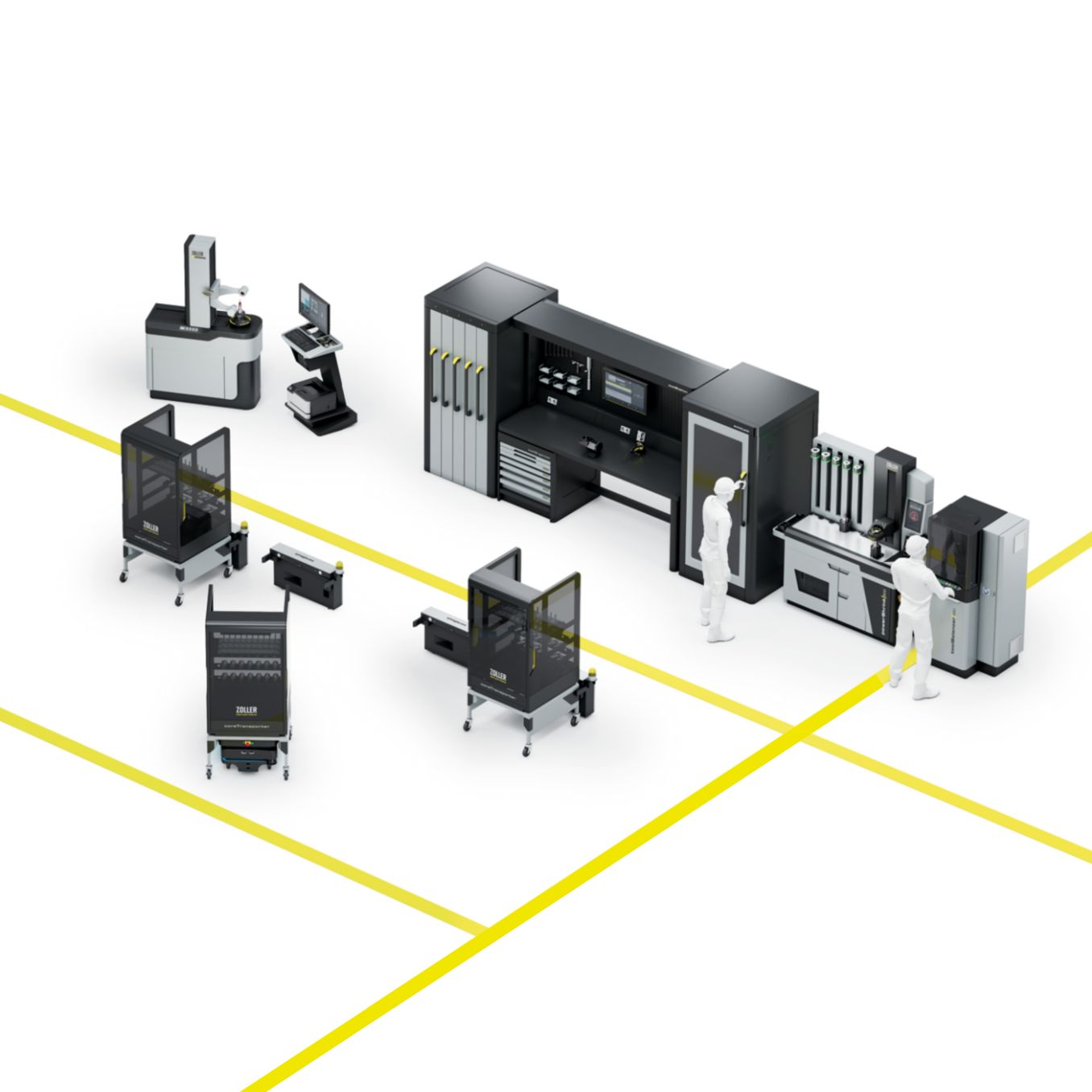

Preparing for the future

Data Leads to Automation

If you establish the systematic tool management of ZOLLER throughout the entire process, you create all the important prerequisites for taking the next step: Automation.

At ZOLLER, tool management, database, software, data transfer and data quality are prepared in such a way that you can start automating processes at any time. With ZOLLER, you automate:

- Tool assembly

- Presetting and measuring

- Tool inspection and documentation

- Tool storage and dispensing

- Tool logistics on the shop floor

- Cleaning, laser marking, shrinking and more