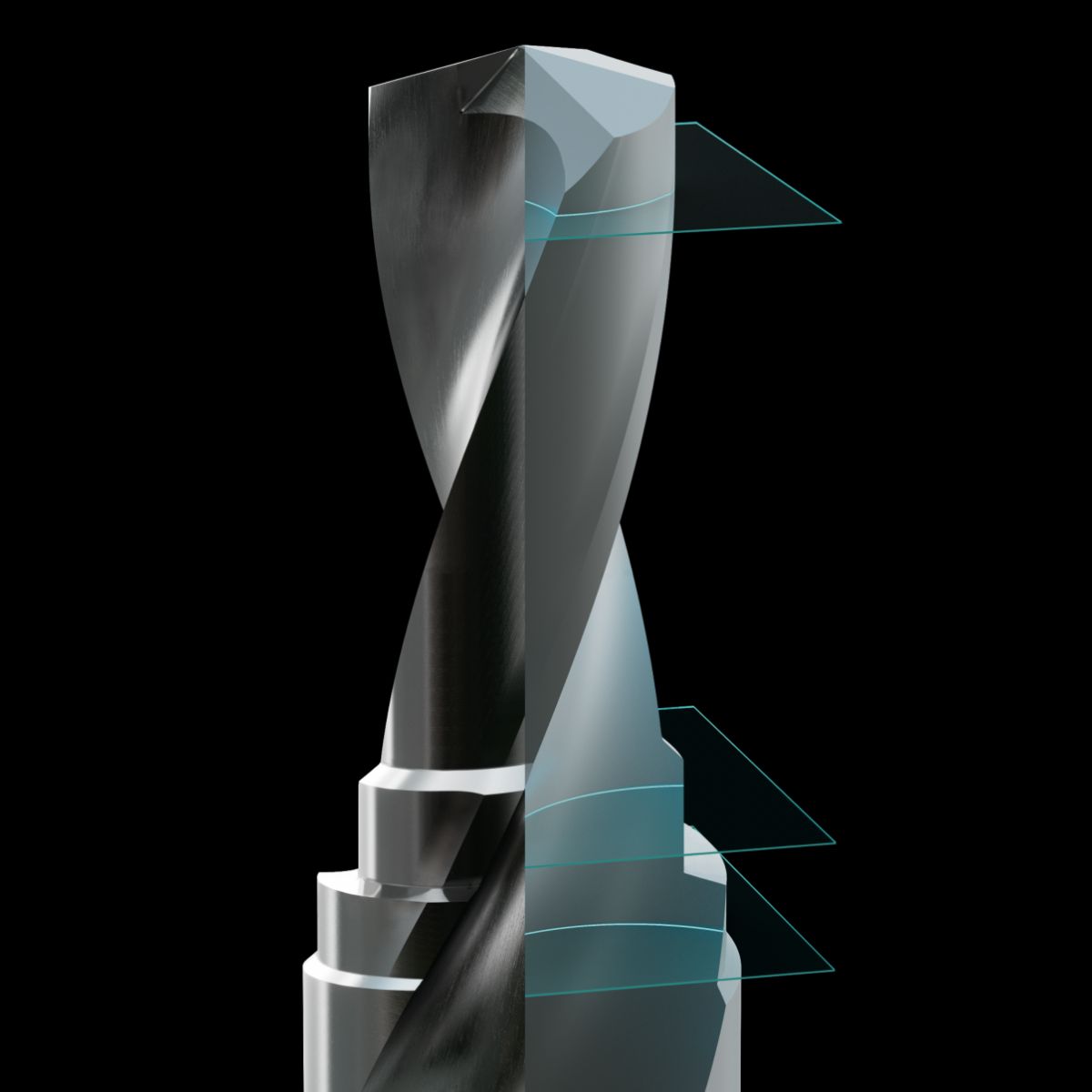

Precise Data on Geometries

For cutting companies

With the presetting and measuring machines from ZOLLER, you can generate detailed data records on tool geometries from µm-precise measurements. With this information, you can exploit the high quality potential of tools and CNC machines.

For tool manufacturers

ZOLLER’s presetting and measuring machines measure grinding wheel packs with high precision. The measurement data obtained is a prerequisite for CNC grinding machines in order to achieve the best results in the grinding process.

The data from the process-oriented measuring machines of the »pom« series from ZOLLER prove the quality. This allows you to quickly record geometry data for initial sample inspections and random samples.

For grinding shops

The measuring machines of the »pom« series also provide precise data for tool wear analyses of used tools. You can forward the measured values in controller format directly to the CNC grinding machine for regrinding jobs.

Quality check and adjustment

Inspecting Tools Close to the Process

Within seconds, the process-oriented measuring devices from ZOLLER record more than 70 parameters – directly next to the machine. The data can be transferred to the CNC grinding machines in controller format.

The data for both grinding and regrinding processes is immediately available on the machine without errors. There is no more efficient and reliable way to get quality on track.

Quality check and adjustment

Inspecting Tools Close to the Process

Within seconds, the process-oriented measuring devices from ZOLLER record more than 70 parameters – directly next to the machine. The data can be transferred to the CNC grinding machines in controller format.

The data for both grinding and regrinding processes is immediately available on the machine without errors. There is no more efficient and reliable way to get quality on track.

Results analysis

Proving Quality with Data

In quality testing, the more comprehensive the data set from the measurements, the more precise the statements about quality.

The measuring machines of the »genius« series are the experts for in‑depth analyses on all tools – optionally including cutting edge preparation and roughness testing. They generate precision data from over 100 parameters and transfer them to the digital tool management system.

This data is then available to control CNC machines, document tool quality and for complete tool histories.

Results analysis

Proving Quality with Data

In quality testing, the more comprehensive the data set from the measurements, the more precise the statements about quality.

The measuring machines of the »genius« series are the experts for in‑depth analyses on all tools – optionally including cutting edge preparation and roughness testing. They generate precision data from over 100 parameters and transfer them to the digital tool management system.

This data is then available to control CNC machines, document tool quality and for complete tool histories.