Order in the Tool Store

The z.One database and the TMS Tool Management Solutions software keep the tool data in a production facility in order.

This order is a prerequisite for consistent data availability in CAM to part processes.

Order in the Tool Store

The z.One database and the TMS Tool Management Solutions software keep the tool data in a production facility in order.

This order is a prerequisite for consistent data availability in CAM to part processes.

Find tools and use them productively

Data Perfectly Organized

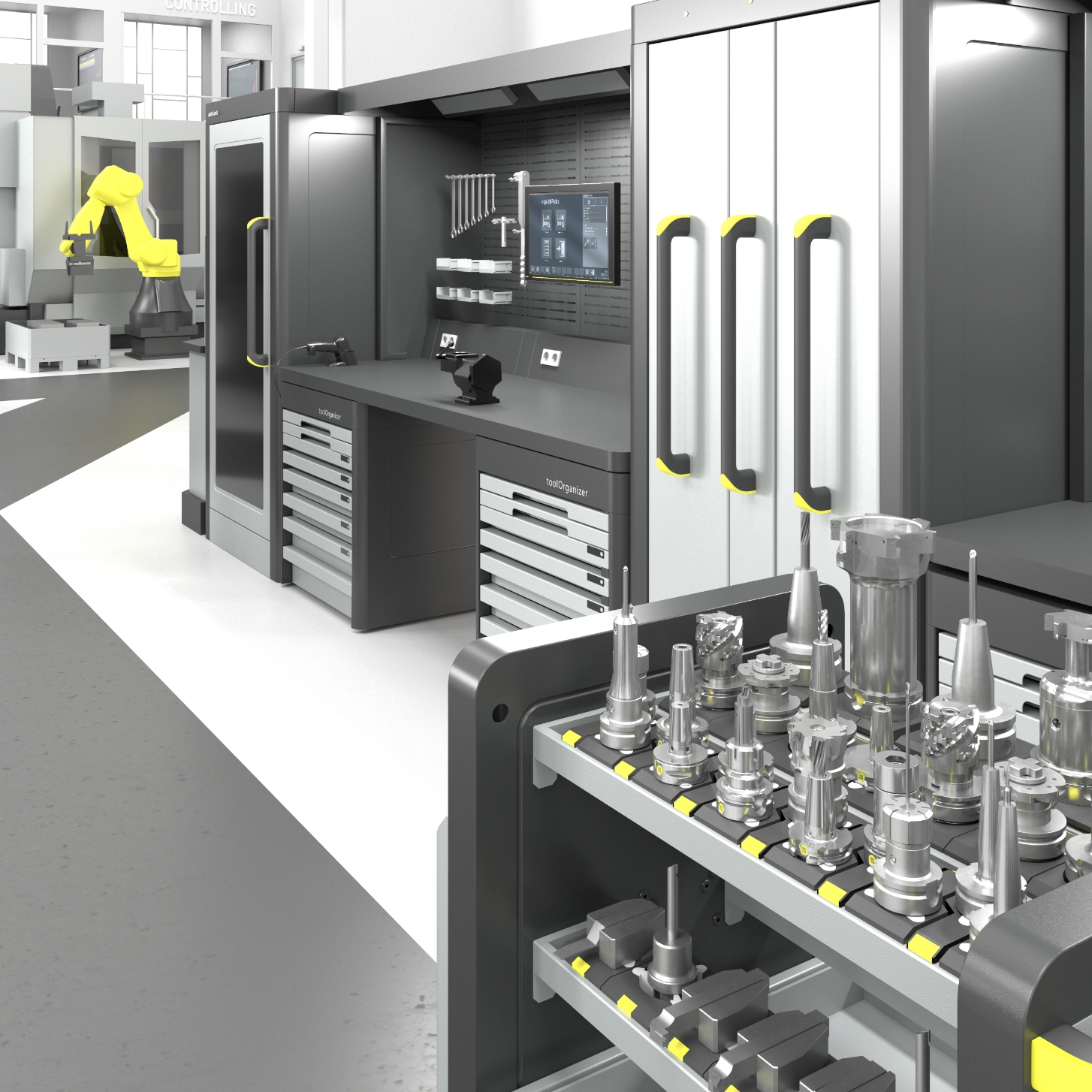

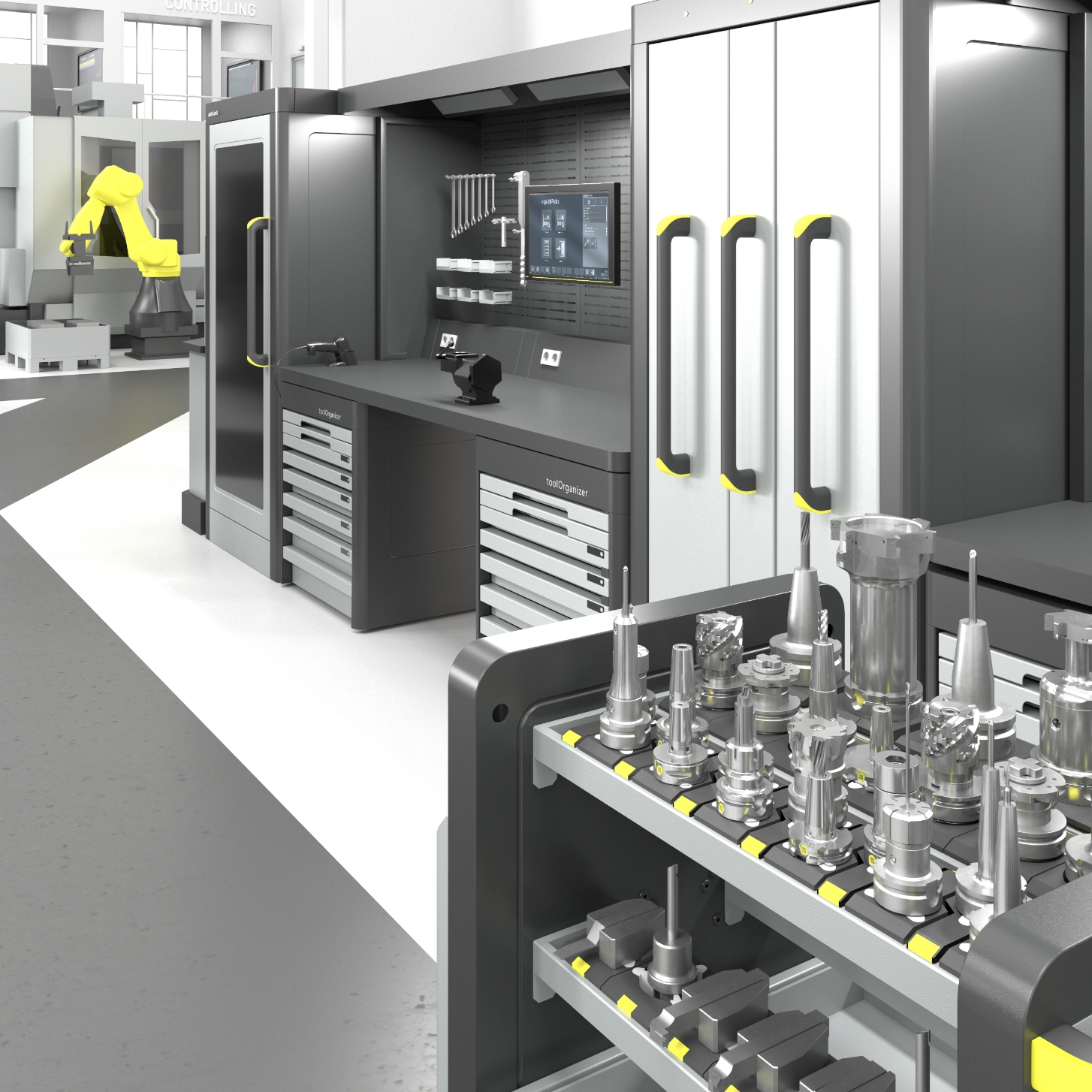

Order in the tool store means: tools have their fixed locations and all tool data can be called up. ZOLLER's Smart Cabinets provide order for tools. The Gold, Silver and Bronze software packages from TMS Tool Management Solutions are responsible for keeping the data in order.

This gives you access to the basic and geometry measurement data of a tool. You also know the stock of cutting inserts, tool holders, complete tools, clamping devices and inspection tools. The storage location management shows you what is where and which tools are currently in use. This comprehensive ZOLLER software can also be used to organize repeat orders.

The TMS Tool Management Solutions are the efficient control center for your data management and the perfect partner for the ZOLLER Smart Cabinets.

Find tools and use them productively

Data Perfectly Organized

Order in the tool store means: tools have their fixed locations and all tool data can be called up. ZOLLER's Smart Cabinets provide order for tools. The Gold, Silver and Bronze software packages from TMS Tool Management Solutions are responsible for keeping the data in order.

This gives you access to the basic and geometry measurement data of a tool. You also know the stock of cutting inserts, tool holders, complete tools, clamping devices and inspection tools. The storage location management shows you what is where and which tools are currently in use. This comprehensive ZOLLER software can also be used to organize repeat orders.

The TMS Tool Management Solutions are the efficient control center for your data management and the perfect partner for the ZOLLER Smart Cabinets.

Store experience

Extensive Data Availability

TMS Tool Management Solutions provide you with a lot of additional information. For example, cutting data can be expanded with comments from the production team. This allows you to build up an internal knowledge base on tools, applications and production details.

Further advantages of high data availability with ZOLLER:

- Manage calibration and certification of inspection equipment

- Retrieve updated tool life data from the CNC machine

- Recognize tool availability

- Create evaluations for tools

- Create setup sheets with editable cutting data

- Record article characteristics

- Call up procurement data

Store experience

Extensive Data Availability

TMS Tool Management Solutions provide you with a lot of additional information. For example, cutting data can be expanded with comments from the production team. This allows you to build up an internal knowledge base on tools, applications and production details.

Further advantages of high data availability with ZOLLER:

- Manage calibration and certification of inspection equipment

- Retrieve updated tool life data from the CNC machine

- Recognize tool availability

- Create evaluations for tools

- Create setup sheets with editable cutting data

- Record article characteristics

- Call up procurement data

Import, convert, transfer

Data Base: Keep It Simple

To create the database, import DIN and ISO-compliant tool data (e.g. DIN4000 / ISO13399) from one of the common directories such as ToolsUnited. The appropriate ZOLLER interface feeds the data directly into the TMS Tool Management Solutions.

You can then convert the data to suit your CAM or simulation system. ZOLLER provides interfaces to 27 CAD/CAM solutions and is the only manufacturer in the world to offer you this added value.

Your benefits include: production-related work preparation, seamless connection to subsequent processes and shorter run-in times.

Import, convert, transfer

Data Base: Keep It Simple

To create the database, import DIN and ISO-compliant tool data (e.g. DIN4000 / ISO13399) from one of the common directories such as ToolsUnited. The appropriate ZOLLER interface feeds the data directly into the TMS Tool Management Solutions.

You can then convert the data to suit your CAM or simulation system. ZOLLER provides interfaces to 27 CAD/CAM solutions and is the only manufacturer in the world to offer you this added value.

Your benefits include: production-related work preparation, seamless connection to subsequent processes and shorter run-in times.