Process Reliability

The µm-precise measuring and presetting data from the ZOLLER measuring technology makes a significant contribution to ensuring that process reliability remains at the highest level.

The »smile« and »venturion« presetting and measuring machines, each ZOLLER measuring machine and all ZOLLER inspection machines are designed for data exchange in production.

You can display current geometry data on tools and grinding wheels at any time or transfer it directly to your CNC machines. With ZOLLER you can manufacture safely.

Process Reliability

The µm-precise measuring and presetting data from the ZOLLER measuring technology makes a significant contribution to ensuring that process reliability remains at the highest level.

The »smile« and »venturion« presetting and measuring machines, each ZOLLER measuring machine and all ZOLLER inspection machines are designed for data exchange in production.

You can display current geometry data on tools and grinding wheels at any time or transfer it directly to your CNC machines. With ZOLLER you can manufacture safely.

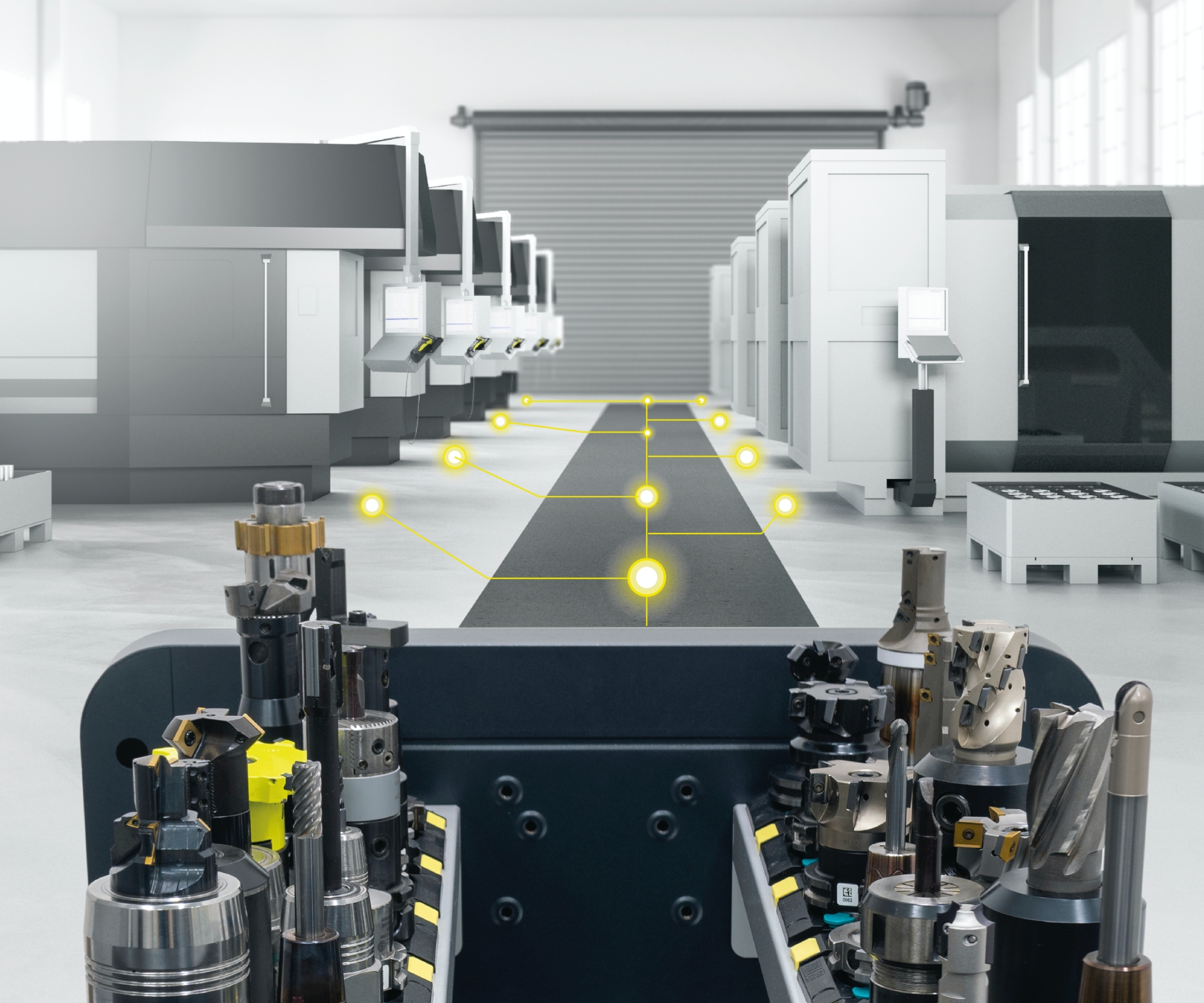

From A to B

Getting Data Safely On Its Way

Data transfer is a key aspect of process reliability. In particular, measured values from presetting and measuring machines should not be transferred manually to the CNC production machine. The risk of errors is high and the potential consequences can be costly.

ZOLLER offers several options for automating this process step – regardless of the manufacturer of a machine:

- RFID chip

- Post-processor (DNC system: Distributed Numerical Control)

- Higher-level production control systems

- Encryption of the actual data in a data matrix code and scanning of the code on the machine with »zidCode«

We will be happy to advise you on the best individual option for your production.

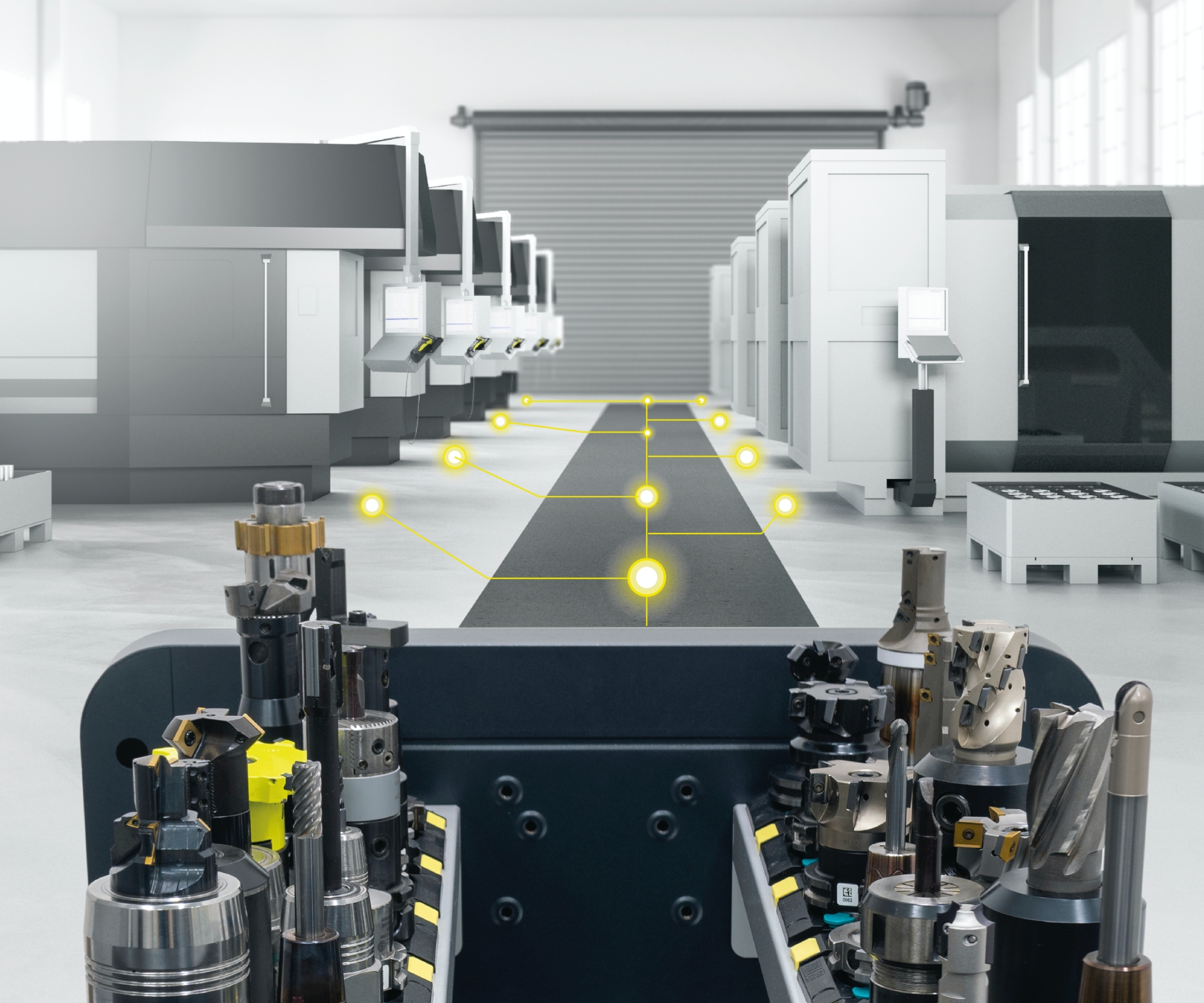

From A to B

Getting Data Safely On Its Way

Data transfer is a key aspect of process reliability. In particular, measured values from presetting and measuring machines should not be transferred manually to the CNC production machine. The risk of errors is high and the potential consequences can be costly.

ZOLLER offers several options for automating this process step – regardless of the manufacturer of a machine:

- RFID chip

- Post-processor (DNC system: Distributed Numerical Control)

- Higher-level production control systems

- Encryption of the actual data in a data matrix code and scanning of the code on the machine with »zidCode«

We will be happy to advise you on the best individual option for your production.