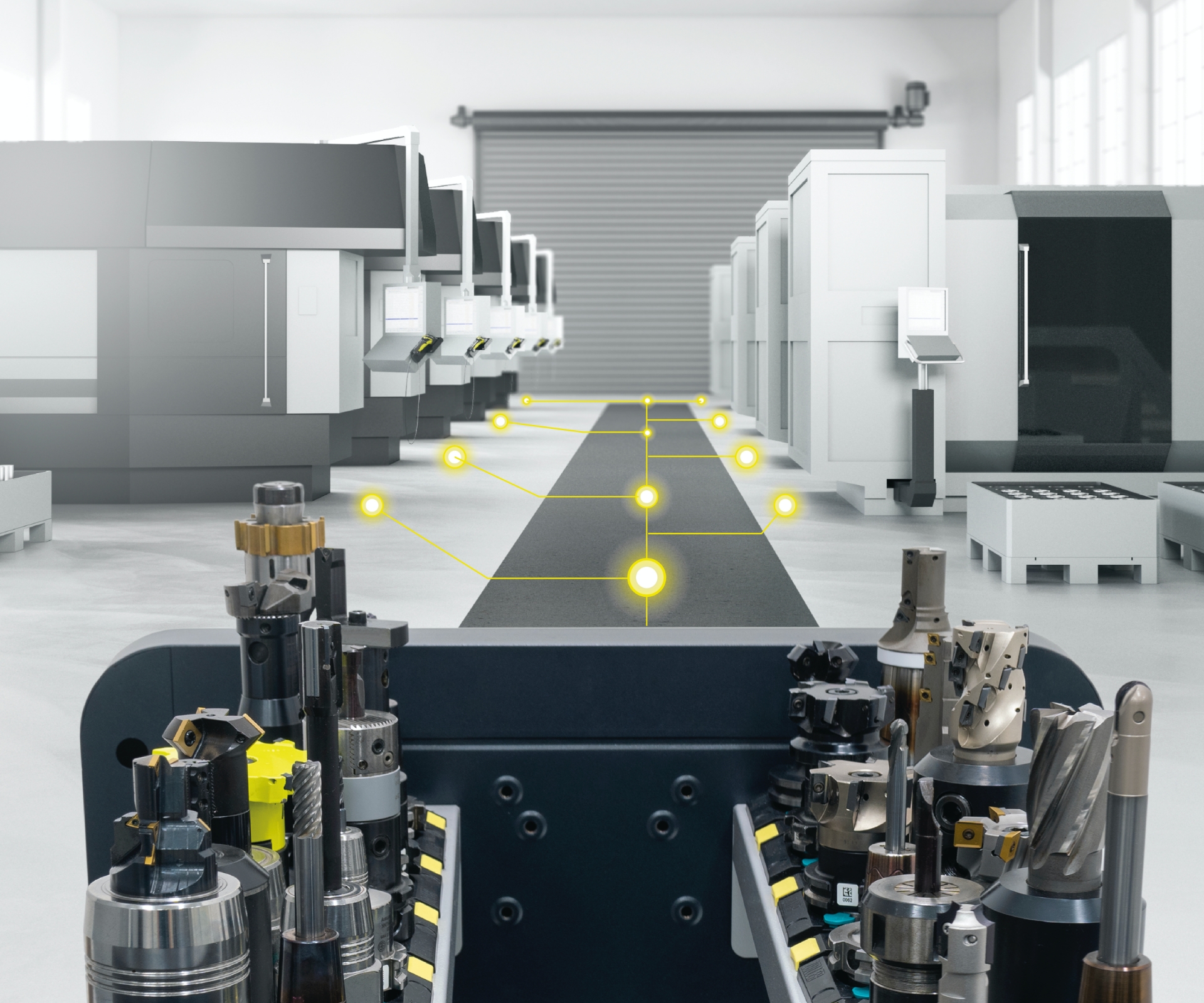

Data flow without a network

With the »zidCode«, your CNC machines are optimally protected against crashes even without a network because the tool data is transmitted error-free to the CNC machine via scanner and code.

This makes »zidCode« the ideal solution for production processes that work without a network. It's also perfect for CNC machines that are not prepared for networks.

Data flow without a network

With the »zidCode«, your CNC machines are optimally protected against crashes even without a network because the tool data is transmitted error-free to the CNC machine via scanner and code.

This makes »zidCode« the ideal solution for production processes that work without a network. It's also perfect for CNC machines that are not prepared for networks.

Integrates seamlessly

The »zidCode« fits into almost any production environment. The solution transfers tool data to the CNC machine via the USB interface. With older machines, data transfer is also easily possible via serial interfaces such as RS232.

Process optimization is only this efficient with ZOLLER.

Integrates seamlessly

The »zidCode« fits into almost any production environment. The solution transfers tool data to the CNC machine via the USB interface. With older machines, data transfer is also easily possible via serial interfaces such as RS232.

Process optimization is only this efficient with ZOLLER.

Small investment for a huge return

With the »zidCode«, you have all the elements for success at your fingertips. You gain security, accuracy and reliability, save time and make it easier for your employees to transfer data to the CNC machine. Even a lean, basic setup will quickly see these benefits.

ZOLLER makes digital progress easy.

Small investment for a huge return

With the »zidCode«, you have all the elements for success at your fingertips. You gain security, accuracy and reliability, save time and make it easier for your employees to transfer data to the CNC machine. Even a lean, basic setup will quickly see these benefits.

ZOLLER makes digital progress easy.

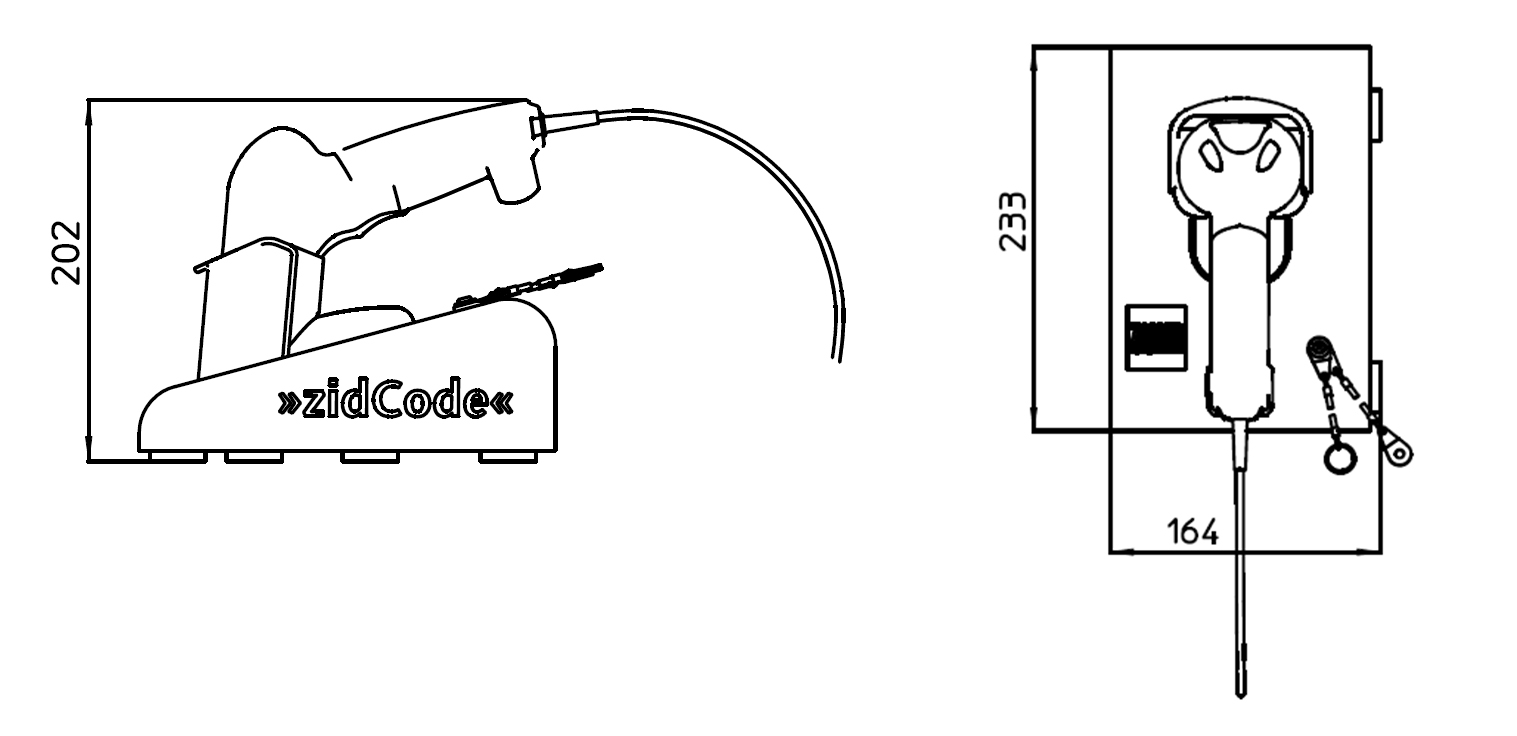

Technical data

Dive into the details for interfaces, requirements and software.

Features

- Barcode reader 1D/2D per CNC machine

- »zidCode« unit per CNC machine

- Software for »zidCode« on the ZOLLER presetting and measuring machine with image processing »pilot 3.0« or »pilot 2 mT«

- USB stick (documentation, instructions, training videos)

- USB cable (connect »zidCode« unit with CNC machine to simulate the keyboard)

Requirements

- CNC machine (controller) with USB connection on which a simulated USB keyboard is recognized. Optional RS232 interface for data output.

- ZOLLER presetting and measuring machine with image processing »pilot 4.0«, »pilot 3.0« or »pilot 2 mT« from version 1.15.0.0, or »pilot 1.0«« from version 1.15.13.0 and thermal label printer