Software

Automation

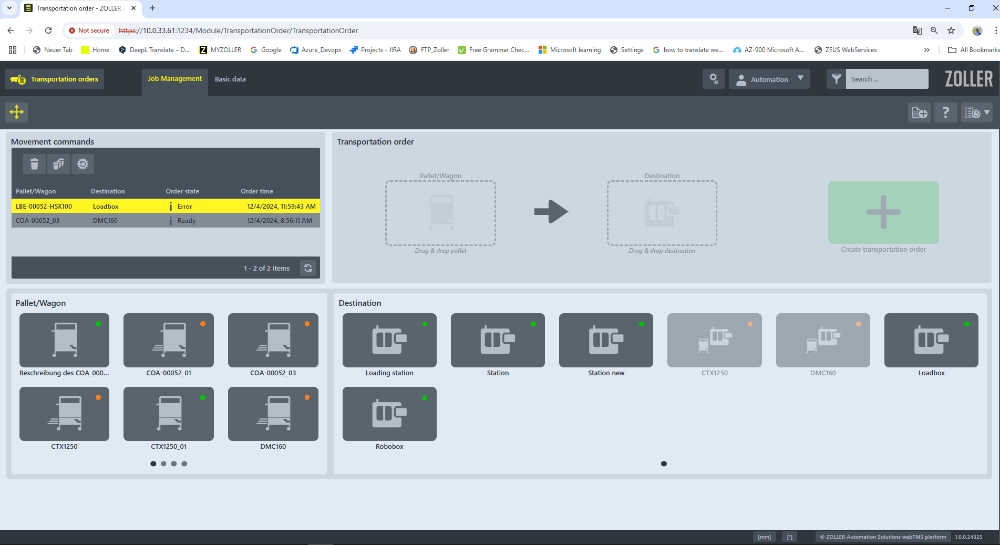

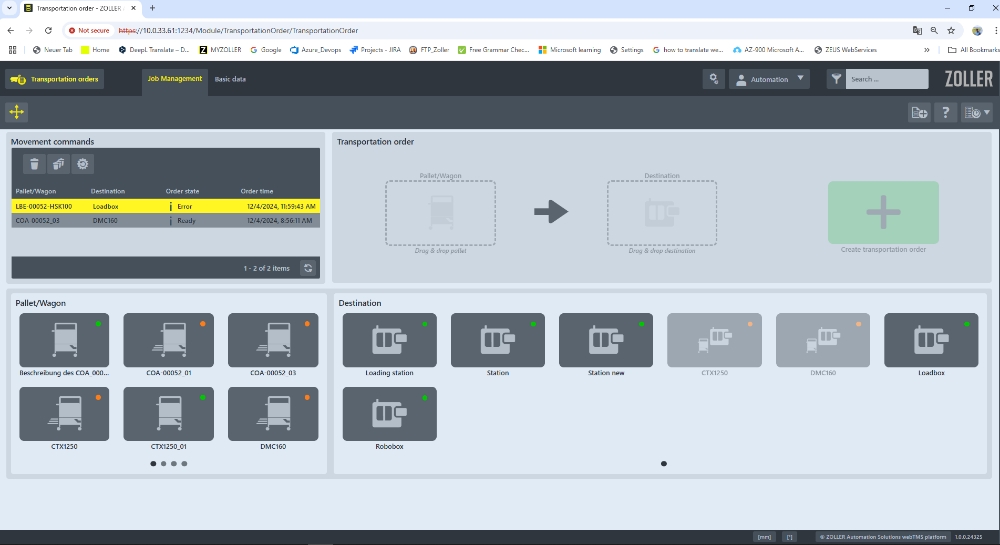

Job management for »coraLogistic«

The job management for »coraLogistic« provides a user-friendly interface for end users, allowing them to manage transport orders easily and efficiently. The user interface allows users to select the trolleys and target machines required to carry out the transport order. By clearly displaying the available options, users can quickly select the most suitable vehicles and target machines for their specific requirements.

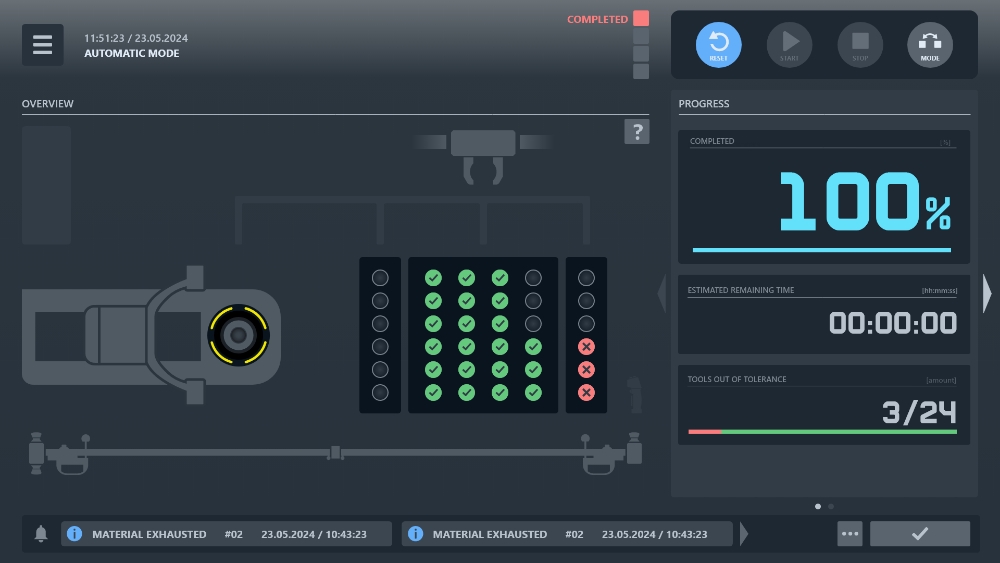

»coraMeasure LG« user interface

Each of the automation cells is controlled via the intelligent »coraMeasure LG« user interface (start, stop, pause). This convenient user interface also provides a clear overview of status, progress and error management. Furthermore, analysis tools show, for example, the number of tools per day or the number of reject tools. The user interface is also equipped with preventive maintenance: every movement and every stroke are tracked and counted so that necessary maintenance measures can be initiated automatically before the individual components break or unpleasant downtimes occur.

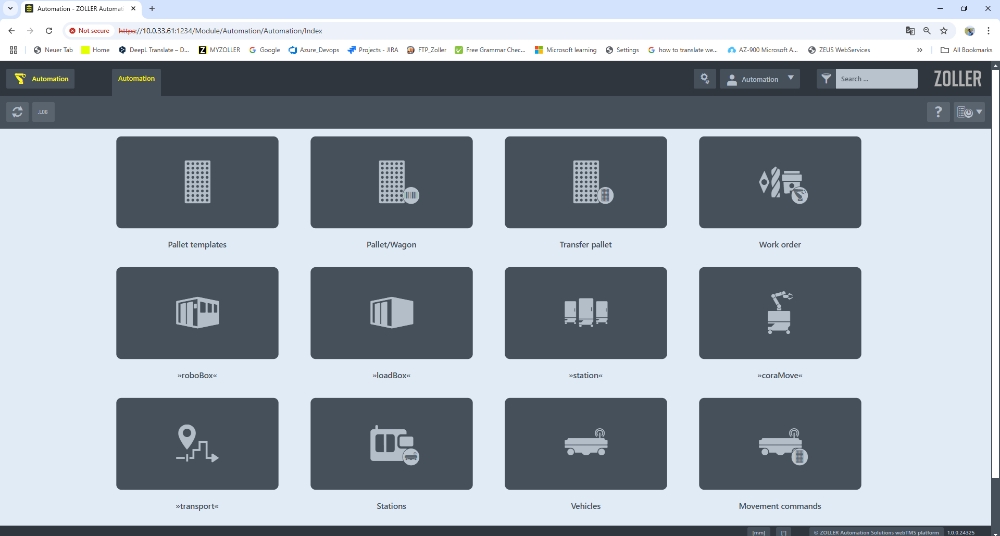

Overview of automation modules

The automation modules provide a comprehensive overview of all available functions that can be used to automate various tasks and processes. These modules are designed to provide an intuitive user interface that allows the operator to navigate effortlessly through the automation process.

»roboBox« user interface

The graphical user interface of the »roboBox« provides a clear overview of all available individual modules, including functions such as measuring, shrinking and cooling. In addition, status indicators are displayed for each module, showing the current status and progress of the robot's running processes. These status indicators allow users to effectively monitor the operation of the robot and identify potential problems in good time.

Order management/tool bookings

Our order management system enables seamless integration of the ZOLLER TMS Tool Management Solutions into the automation processes. With our system, individual tools and setup sheets from ZOLLER TMS can be easily booked directly onto the automation pallets. This ensures that the required tools and setup sheets are available for production precisely and on time.

To minimize errors, we offer the option of scanning DataMatrix codes (DMC) on the places and tools. Scanning these codes ensures that the right tools are placed in the right locations, improving the accuracy and efficiency of your automation processes. With our solution, you can optimize your production processes and maximize the reliability of your tool bookings.

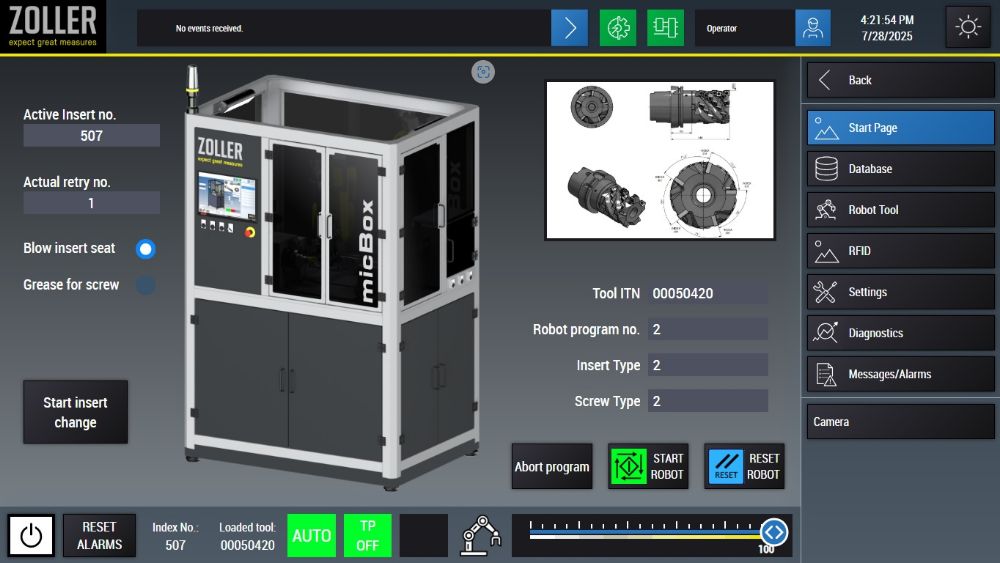

»micBox« start menu

The start page shows all important information at a glance and has a clear, concise and user-friendly surface. The operator receives information on the loaded tool and the current robot status at all times, and messages worth knowing are also reliably displayed. From this central user interface, the operator can quickly navigate to all other areas within the control software. The system can be started with just one click!

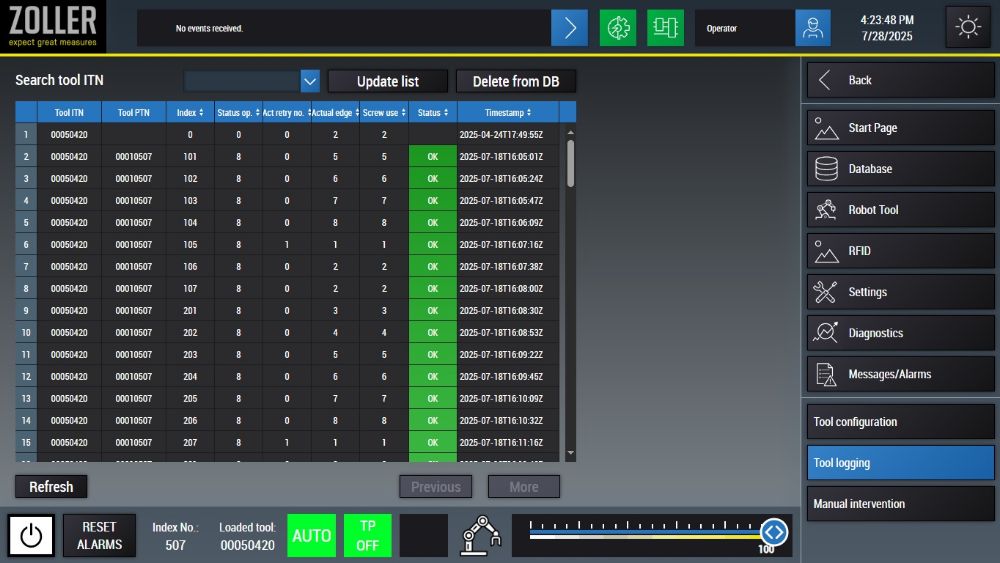

»micBox« database overview

The database overview permits the operator a reliable view of all relevant information on the currently loaded tool. It displays precisely how many indexable inserts have been usage and how often an exchange has already taken place - all automatically monitored and recorded. Practical submenus allow the operator to enter the configuration page, where all necessary tool data can be entered and adjust quickly and simply.

»micBox« user interface

The control's graphical user interface provides a clear overview of all available modules – from the robot control to the rotate and swivel unit to the lubrication station for torquing. Each module can be conveniently controlled manually, as can the robot directly via the software. Important status displays such as robot status, tool ID and messages remain visible at all times – even when exchanging between pages. This ensures maximum transparency and ease of use.

»micBox« tool configuration

Tool configuration is simple for the operator: new tools can be created quickly and all the necessary information for the robot can be entered. Existing tools can also be easily edited and refreshed at any time. The "Delete from DB" and "Write to DB" buttons are used to manage tool data directly and conveniently in the database – deleting or adding tool data is done reliably and smoothly.