Highlights/Hardware of the »redomatic 600«

»ace« High-Precision Spindle

Insert tool, push a button, finished. That’s how simple it is to power-operated clamp tools using the universal »ace« high-precision spindle (all-clamping element) from ZOLLER – always with the same precision, accurate and reliable to the last μm. The universal tool holder adapter exchange system makes it possible to exchange in less than 10 seconds between holder systems such as SK, HSK, PSC, VDI, KM or hydroexpansion. No wonder these poweroperated high-precision spindles have been impressing users throughout the world for decades.

»asza« length setting system

CNC controlled linear adjusting equipment for adjusting tools to length using a limit pin. Alternatively available as »asza-rot«, with which tool length can be optionally set via the automatic rotation of the length adjusting screw (does not apply for shrink-clamping chucks).

MMS technology

In tools for minimum quantity lubrication (MQL), the coolant transfer piece must be applied to the end of the tool shaft with a positive-locking connection. Only then will you have full functionality and reliability in production with MMS tools. Technology from ZOLLER guarantees secure and positive-locking connection to the coolant supply – fully automatically.

22 kVA induction coil with quick change interface

For shrink-clamping larger shrink-clamping holders diameters 1.57 to 2 inch (D 40 to 50 mm) and reinforced shrink-clamping holders (thicker walls). The 22 kVA induction coil can be operated quickly and ergonomically on an alternating basis with the 14 kVA induction coil via a quick exchange interface. The 22 kVA induction coil with shielding washers in diameters 0.63 to 0.79 inch (D 16 to 20 mm), 0.98 to 1.26 inch (D 25 to 32 mm), 1.57 to 2 inch (D 40 to 50 mm) – these are optionally available in a divided version.

Retractable slide unit

If the »redomatic 600« is not in the tool shrink mode, the »redomatic« slide unit can be lowered automatically to park position via software control. This increases the measurable tool diameter up to 31.49 inch (D 800 mm).

Cooling bells with »coolbyLight« user guidance

The cooling bells guide you through the cooling process reliably with the help of the color system, switch over LEDs and a cooling time monitoring:

Steady green: ready for cooling

Flashing green: the cooling bell to be used

Steady red: Shrink-clamping holder hot

Flashing blue: Shrink-clamping holder cooled down

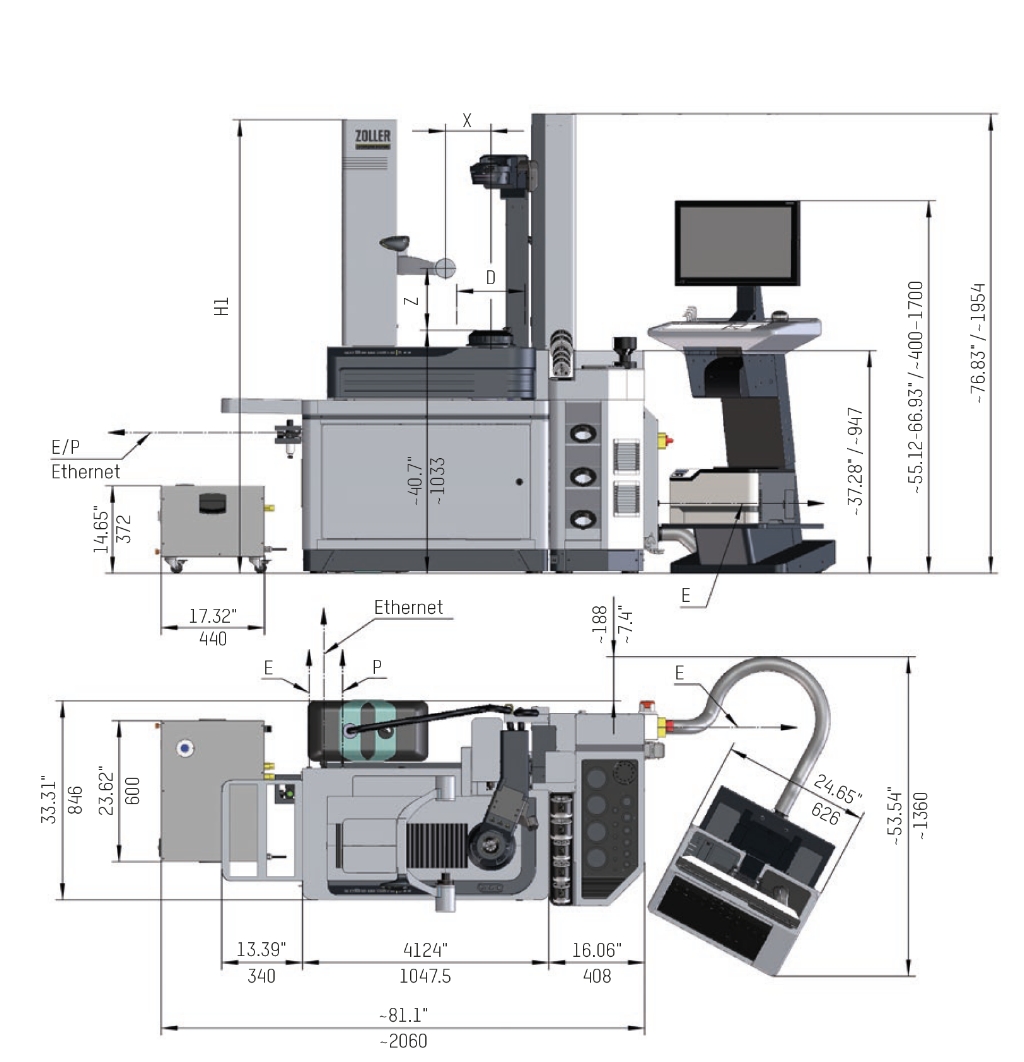

Technical Data and Installation Dimensions

23.62" (600 mm)

Maximum tool length Z

23.62 / 31.5 / 39.4" (600 / 800 / 1000 mm)

Maximum tool length Z

8.27 / 12.2" (210 / 310 mm)

Measuring range X axis

10.63 / 11.8 / 15.75" (270 / 300 / 400 mm)

Measuring range X axis

1.25" (32 mm)

Maximum clampable shank diameter

1.25 / 2" (32 / 50 mm)

Maximum clampable shank diameter

16.54 / 24.4" (420 / 620 mm)

Maximum tool diameter D

21.3 / 23.62 / 31.5" (540 / 600 / 800 mm)

Maximum tool diameter D

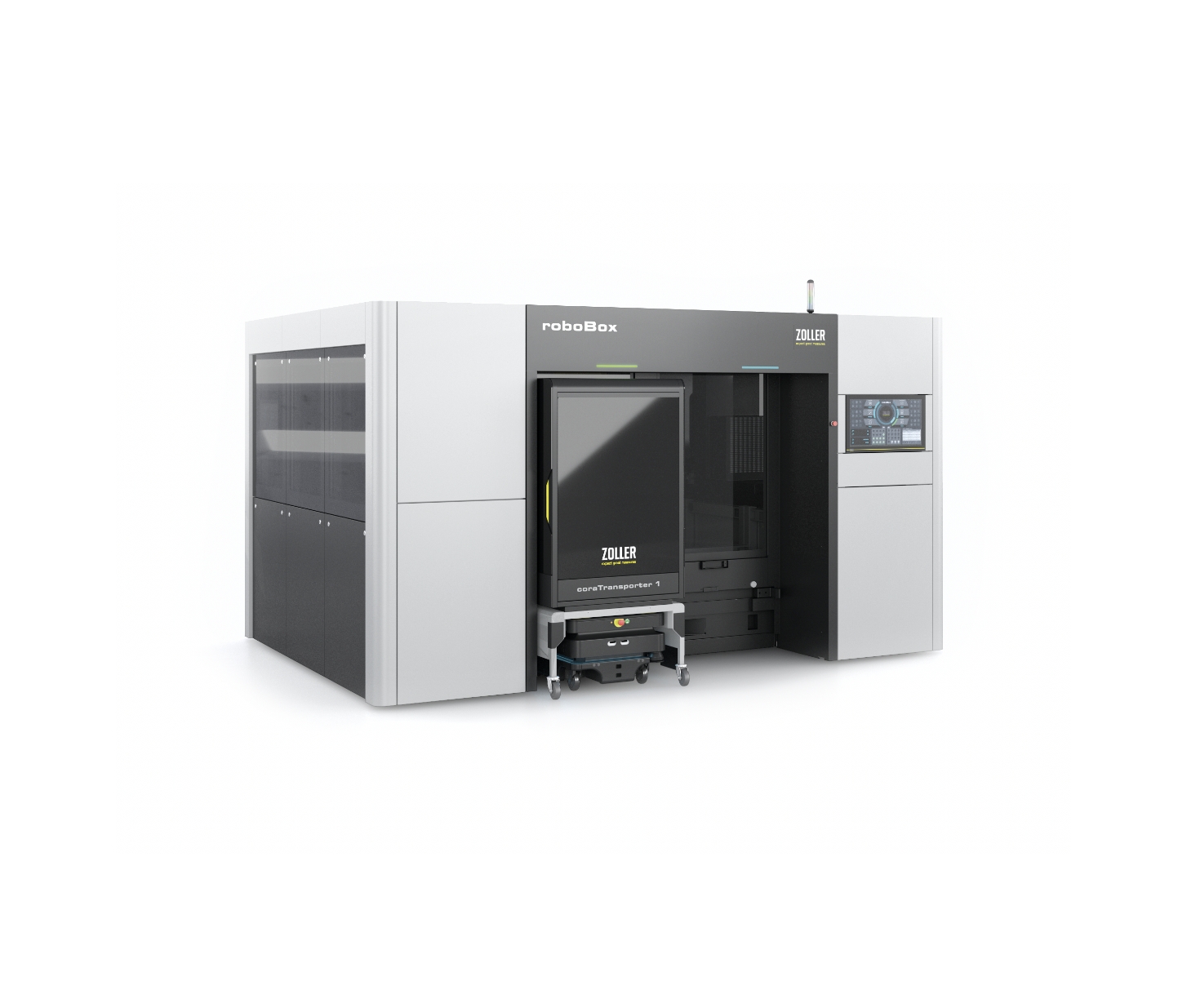

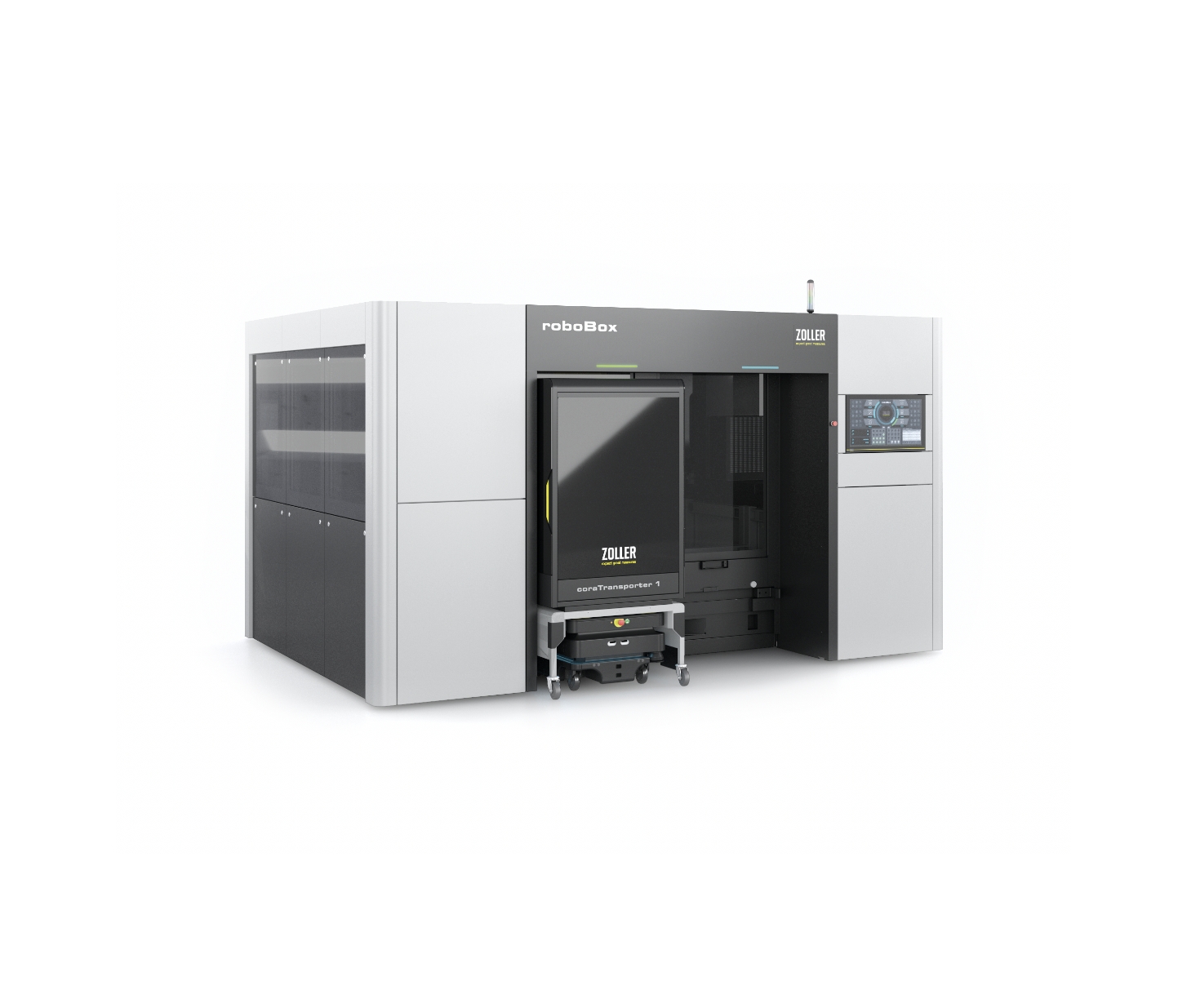

»roboBox« Automation System

If you use multiple shrink-clamping tools each day, you will benefit immediately from the »roboBox«. With up to six modules, you can individually expand the »roboBox« to create a fully automatic system for fitting, measuring and cooling tools. Your advantages: high throughput, high precision, high tool availability.

»roboBox« can handle all shrink-clamping processes independently with just the combination of the three measuring, shrink-clamping, and cooling modules. Work with tools shrink-clamped to a precise length and exactly measured in fully automatic series production. Unclamp tools quickly that have reached the end of their tool life or that are defective. ZOLLER »roboBox« can be easily integrated into any production and put into operation quickly.

»roboBox« Automation System

If you use multiple shrink-clamping tools each day, you will benefit immediately from the »roboBox«. With up to six modules, you can individually expand the »roboBox« to create a fully automatic system for fitting, measuring and cooling tools. Your advantages: high throughput, high precision, high tool availability.

»roboBox« can handle all shrink-clamping processes independently with just the combination of the three measuring, shrink-clamping, and cooling modules. Work with tools shrink-clamped to a precise length and exactly measured in fully automatic series production. Unclamp tools quickly that have reached the end of their tool life or that are defective. ZOLLER »roboBox« can be easily integrated into any production and put into operation quickly.